Micro-cable optical fiber filling paste and preparation method therefor

A technology of optical fiber filling paste and microcable, applied in the direction of fiber mechanical structure, etc., can solve the problems of small cone penetration, insufficient uniformity, clogging, etc., and achieve the effect of excellent high and low temperature performance, simple processing technology, and clean production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

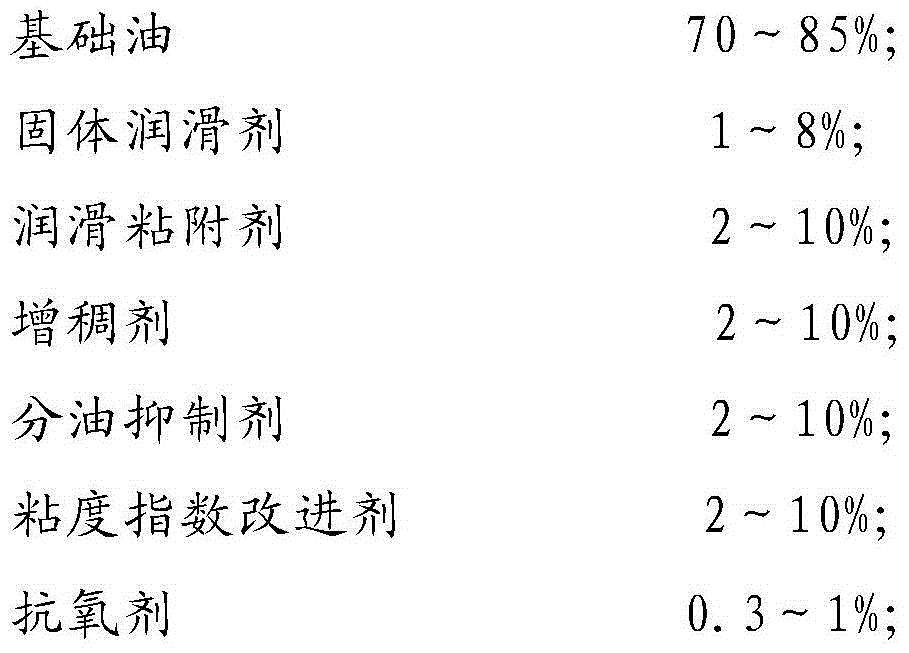

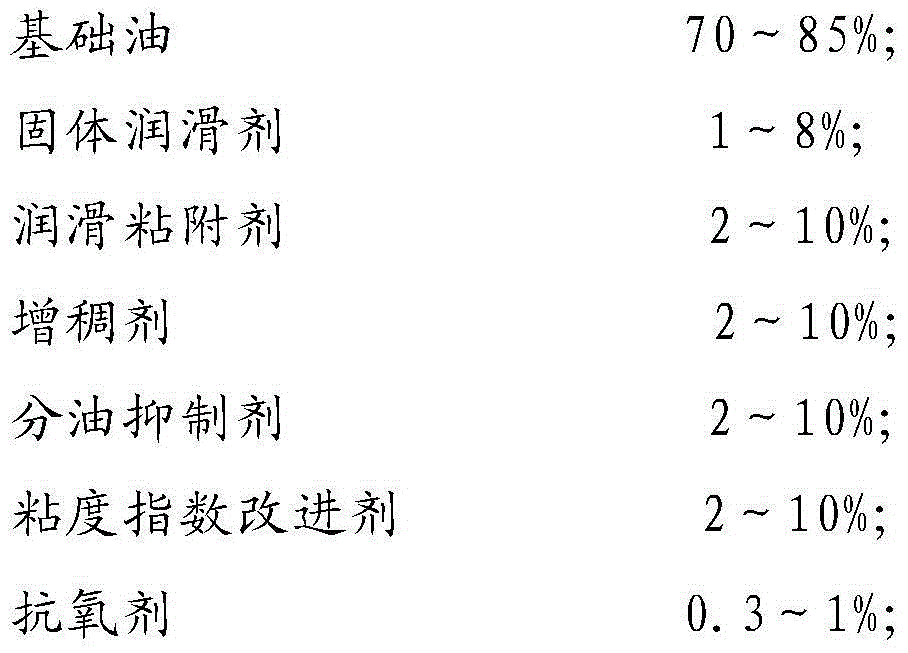

Method used

Image

Examples

Embodiment 1

[0018] Add 50 grams of oil separation inhibitor to 805 grams of base oil, stir well and evenly, start stirring while heating for 1 to 3 hours, when the temperature rises to 100°C, add 20 grams of viscosity index improver, continue heating and stirring 2 to 5 hours, when the temperature rises to 160°C, stop heating, add 20 grams of solid lubricant and 60 grams of lubricating adhesive, keep warm and stir for 1 to 3 hours, then add 5 grams of antioxidant and stir for 0.5-1 hour , and then lower the temperature to 50°C to 80°C, add 40 grams of thickener, fully feed back and stir for 1 to 3 hours, homogeneously grind, and vacuum degas, the final product obtained is a transparent colloid.

[0019] Among the above-mentioned raw materials, the base oil is GTL base oil produced by Shell, the solid lubricant is CF-5000 fluorinated graphite from Shanghai Fubon Chemical Co. The block polyisobutylene with an average molecular weight of 50000, the oil separation inhibitor is selected from t...

Embodiment 2

[0022] Add 45 grams of oil separation inhibitor to 800 grams of base oil, stir fully and evenly, start stirring while heating for 1 to 3 hours, when the temperature rises to 100°C, add 25 grams of viscosity index improver, continue heating and stirring 2-5 hours, when the temperature rises to 160°C, stop heating, add 15 grams of solid lubricant and 65 grams of lubricating adhesive, keep warm and stir for 1-3 hours, then add 5 grams of antioxidant and stir for 0.5-1 hour , and then lower the temperature to 50°C to 80°C, add 45 grams of thickener, fully feed back and stir for 1 to 3 hours, homogeneously grind, and vacuum degas, the final product obtained is a transparent colloid.

[0023] Among the above raw materials, the base oil is PAO-6 synthetic oil produced by Exxon Mobil Corporation, and the rest of the raw materials are the same as in Example 1.

[0024] The main indicators of the final product after testing are: appearance (colloidal and transparent); thixotropic index ...

Embodiment 3

[0026] Add 40 grams of oil separation inhibitor to 795 grams of base oil, stir well and evenly, start stirring while heating for 1 to 3 hours, when the temperature rises to 100°C, add 15 grams of viscosity index improver, continue heating and stirring 2 to 5 hours, when the temperature rises to 160°C, stop heating, add 25 grams of solid lubricant and 70 grams of lubricating adhesive, keep warm and stir for 1 to 3 hours, then add 5 grams of antioxidant and stir for 0.5-1 hour , and then lower the temperature to 50°C to 80°C, add 50 grams of thickener, fully feed back and stir for 1 to 3 hours, homogeneously grind, and vacuum degas, the final product obtained is a transparent colloid.

[0027] Among the above raw materials, the base oil is a mixture of GTL base oil produced by Shell and PAO-6 synthetic oil produced by ExxonMobil, and the mixing ratio is 1:1, and the rest of the raw materials are the same as in Example 1.

[0028] The main indicators of the final product after te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com