High-temperature- and high-voltage-resistant high-insulating-property ignition cable

A high-temperature and high-voltage technology, applied in the field of high-temperature, high-voltage, and high-insulation ignition cables, can solve the problems of the multi-layer metal shielding body of the ignition cable exceeding the specified requirements, the electromagnetic shielding performance not meeting the requirements of harsh use environments, etc. Achieve the effect of avoiding electromagnetic leakage point defects, strong adaptability to harsh environments, and small electromagnetic leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

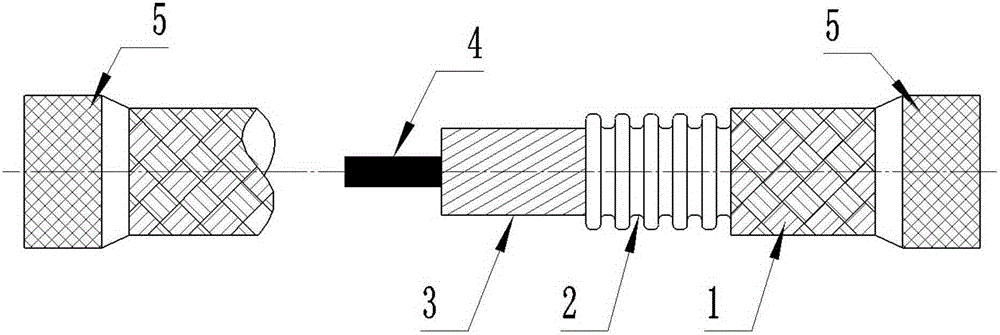

[0017] refer to figure 1 . In the embodiment described below, the ignition cable with high temperature resistance, high voltage and high insulation performance includes an outer shield, an intermediate layer and an inner layer insulator, wherein the nickel core conductor 4 passes through the inner layer insulator 3 . The outer shielding body 1 consists of a stainless steel mesh sleeve and a metal pipe with a regular wave shape, the middle insulating layer is an insulator wrapped with soft filaments and fine sand, and the two ends are needle or hole ceramic / metal Sealed high temperature resistant connectors. The outer shielding body can use stainless steel wire braided mesh sleeve and / or layered silicone sleeve as the shielding body protection structure. The corrugated metal hose can be a nickel alloy corrugated hose that is easy to bend and can seal the shielding structure. It is convenient to realize the overall sealing of the ignition cable, improve the high-altitude perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com