Electrician-used insulated soft composite material preparation method

A composite material and manufacturing method technology, applied in the direction of insulators, circuits, electrical components, etc., can solve problems affecting the safety and reliability of motors, incomplete curing of adhesives, and unfavorable bonding performance, so as to improve safety and reliability , easy to operate, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

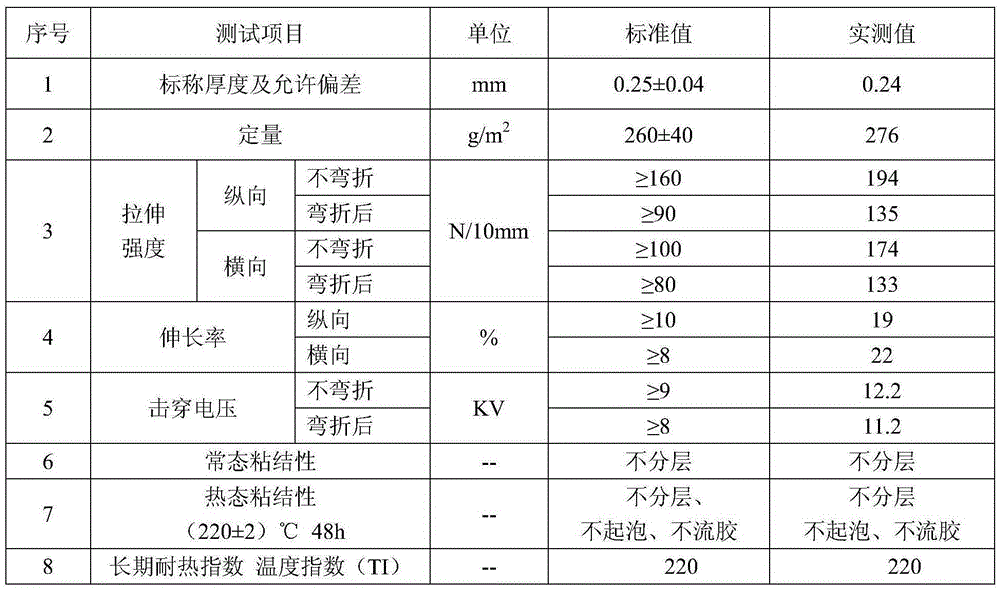

Examples

Embodiment 1

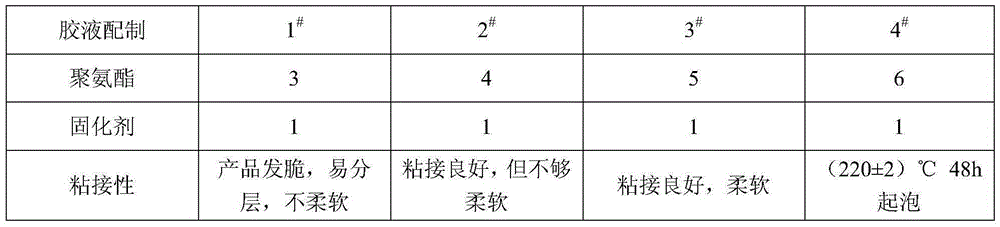

[0037] Step 1. Glue preparation: in parts by mass, take 5 parts of polyurethane main agent and dissolve with 8 parts of ethyl acetate, then add 1 part of curing agent to mix, and stir evenly to obtain polyurethane glue.

[0038] Step 2. Glue coating: After the polyurethane glue is prepared, set the temperature of the oven to 55°C in zone I, 100°C in zone II, and 105°C in zone III. The polyaramid fiber paper is unrolled at the same time, and the speed of the machine is 10m / min. Polyurethane glue is coated on both sides of the polyimide film, and then dried in an oven to obtain a polyimide film with glue. The amount of dry glue on the imide film is 18g / m 2 .

[0039] Step 3: Composite and winding: the polyaramid fiber paper passes through the guide roller, and is composited with the glued polyimide film exiting the oven, and then wound to obtain a roll-shaped composite material with a winding tension of 35N.

[0040] Step 4. Post-curing treatment: Post-cure the rolled product....

Embodiment 2

[0050] Step 1. Glue preparation: in parts by mass, take 5 parts of polyurethane main agent and dissolve it with 7 parts of ethyl acetate, then add 1 part of curing agent to mix, and stir evenly to obtain polyurethane glue.

[0051] Step 2. Glue coating: After the polyurethane glue is prepared, set the oven temperature to 50°C in zone I, 90°C in zone II, and 90°C in zone III. After the temperature of the oven rises to the set value, drive the polyimide film and The polyaramid fiber paper is unrolled at the same time, and the speed of the machine is 10m / min. Polyurethane glue is coated on both sides of the polyimide film, and then dried in an oven to obtain a polyimide film with glue. The amount of dry glue on the imide film is 20g / m 2 .

[0052] Step 3: Composite and winding: the polyaramid fiber paper passes through the guide roller, and is composited with the glued polyimide film exiting the oven, and then wound to obtain a roll-shaped composite material with a winding tensi...

Embodiment 3

[0055] Step 1. Glue preparation: in parts by mass, take 5 parts of polyurethane main agent and dissolve it with 9 parts of ethyl acetate, then add 1 part of curing agent to mix, and stir evenly to obtain polyurethane glue.

[0056] Step 2. Glue application: After the polyurethane glue is prepared, set the temperature of the oven to 60°C in zone I, 105°C in zone II, and 105°C in zone III. The polyaramid fiber paper is unrolled at the same time, and the speed of the machine is 10m / min. Polyurethane glue is coated on both sides of the polyimide film, and then dried in an oven to obtain a polyimide film with glue. The amount of dry glue on the imide film is 14g / m 2 .

[0057] Step 3: Compounding and winding: the polyaramid fiber paper passes through the guide roller, and is compounded with the glued polyimide film exiting the oven, and then wound to obtain a roll-shaped composite material with a winding tension of 40N.

[0058] Step 4, post-curing treatment: Post-cure the rolled p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| winding tension | aaaaa | aaaaa |

| winding tension | aaaaa | aaaaa |

| winding tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com