Ultraviolet-heat dual-curing adhesive and application thereof

An adhesive and dual-curing technology, applied in the direction of adhesives, non-polymer organic compound adhesives, adhesive types, etc., can solve problems such as cracking, falling off, lens shifting, etc., to prevent shifting, reduce curing shrinkage, The effect of improving the ability to resist cold and heat shocks and external shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

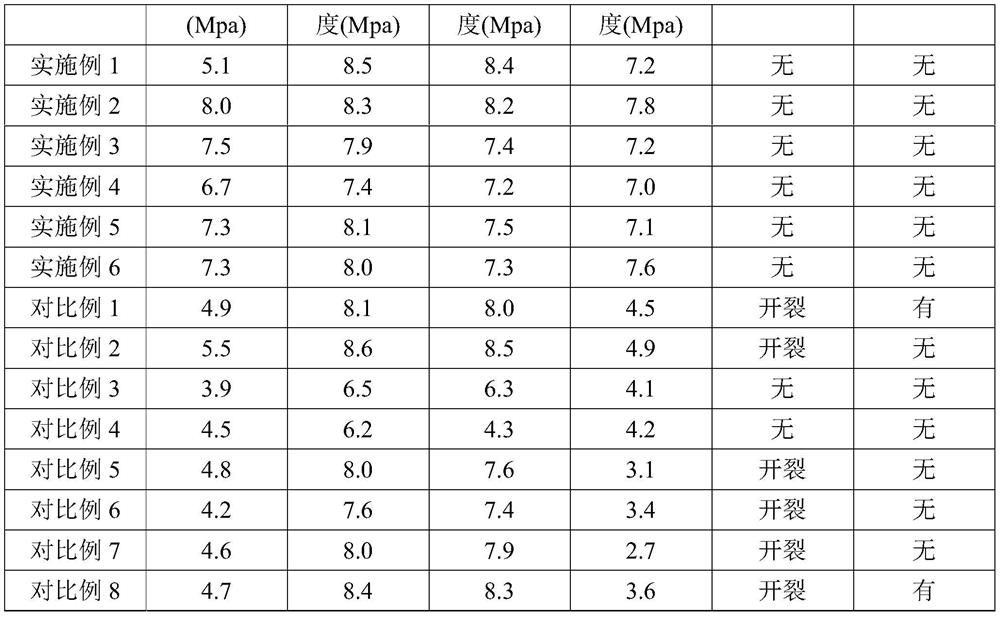

Examples

Embodiment 1

[0069] This embodiment provides a UV-heat dual curing adhesive, comprising the following components in parts by weight:

[0070] 55 parts of cycloaliphatic epoxy resin, 25 parts of bisphenol A epoxy resin, 1 part of 3-ethyl-3-oxetanol, 1 part of styrene-butadiene rubber-acrylic resin core-shell toughener, polyamide 1 part of resin powder, 1 part of 1-hydroxycyclohexyl phenyl ketone, 5 parts of blocked hexafluoroantimonate and 1 part of fumed silica.

[0071] The preparation method of described ultraviolet-heat dual curing adhesive is as follows:

[0072] (1) 55kg cycloaliphatic epoxy resin, 25kg bisphenol A type epoxy resin, 1kg 3-ethyl-3-oxetanemethanol, 1kg styrene-butadiene rubber-acrylic resin core-shell toughener and 1kg polystyrene After the amide resin powder is weighed, drop into the mixing tank and stir, the stirring speed is set as 90rpm, and stirs for 10 minutes;

[0073] (2) Continue to add 5kg closed type hexafluoroantimonate (CXC-1612 of U.S. King's Industries ...

Embodiment 2

[0076] This embodiment provides a UV-heat dual curing adhesive, comprising the following components in parts by weight:

[0077] 30 parts of cycloaliphatic epoxy resin, 10 parts of bisphenol A epoxy resin, 10 parts of isobornyl acrylate, 10 parts of polybutadiene-acrylic resin core-shell toughener, 5 parts of polyamide resin powder, diphenyl 5 parts of ketone, 1 part of blocked hexafluoroantimonate and 2 parts of fumed silica.

[0078] The preparation method of described ultraviolet-heat dual curing adhesive is as follows:

[0079] (1) 30kg cycloaliphatic epoxy resin, 10kg bisphenol A type epoxy resin, 10kg isobornyl acrylate, 10kg polybutadiene-acrylic resin core-shell toughening agent and 5kg polyamide resin powder are weighed and dropped into Stir in the mixing tank, the stirring speed is set as 90rpm, and stir for 10 minutes;

[0080] (2) Continue to add 1kg closed type hexafluoroantimonate (KGI Applied Materials Co., Ltd. VicbaseTC3630) and 5kg benzophenone to stir in t...

Embodiment 3

[0083] This embodiment provides a UV-heat dual curing adhesive, comprising the following components in parts by weight:

[0084] 30 parts of cycloaliphatic epoxy resin, 25 parts of bisphenol A epoxy resin, 5 parts of isobornyl acrylate, 5 parts of polybutadiene-acrylic resin core-shell toughening agent, 3 parts of polymethyl methacrylate resin powder 2.5 parts of benzophenone, 2.5 parts of blocked hexafluoroantimonate and 5 parts of fumed silica.

[0085] The preparation method of described ultraviolet-heat dual curing adhesive is as follows:

[0086] (1) 30kg cycloaliphatic epoxy resin, 25kg bisphenol A type epoxy resin, 5kg isobornyl acrylate, 5kg polybutadiene-acrylic resin core-shell toughening agent and 3kg polymethyl methacrylate resin powder After weighing, put into the mixing tank and stir, the stirring speed was set at 90rpm, and stirred for 10 minutes;

[0087] (2) Continue to add 2.5kg of closed hexafluoroantimonate (Kage Applied Materials Co., Ltd. Vicbase TC3630...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com