Solid laser with adjustable pulse width from hundred picoseconds to nanosecond

A solid-state laser, nanosecond pulse technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of complex laser structure and high cost, and achieve the effect of good beam quality, simple structure and low technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

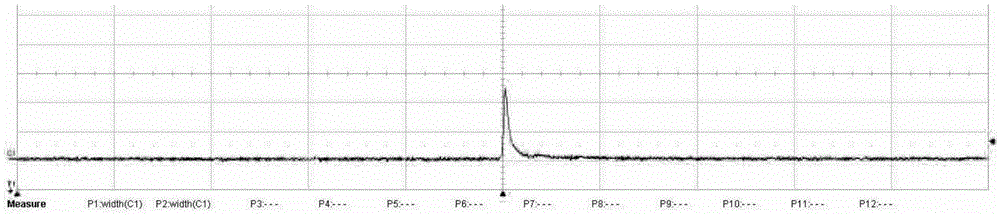

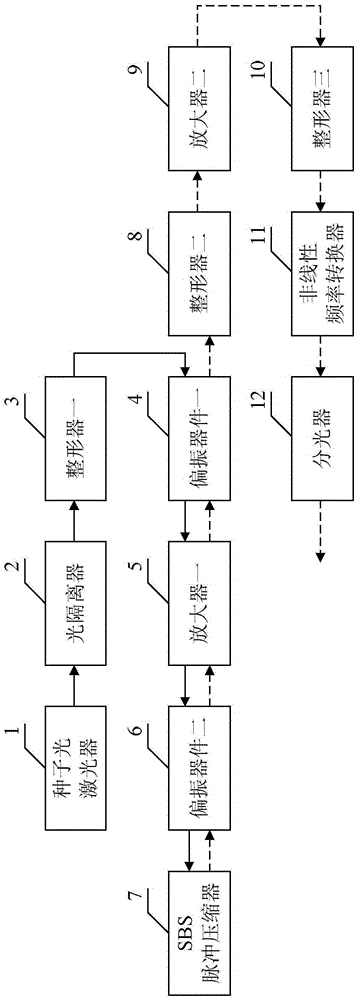

[0016] Specific implementation mode one: combine Figure 1 to Figure 9 , Figure 14 to Figure 17 Describe this embodiment mode, a solid-state laser with adjustable pulse width from picoseconds to nanoseconds described in this embodiment mode includes a seed optical laser 1, an optical isolator 2, a shaper 3, a polarization device 4, and an amplifier 1 5. Polarization device two 6, SBS pulse compressor 7, shaper two 8 and amplifier two 9;

[0017] The linearly polarized light generated by the seed light laser 1 passes through the optical isolator 2, the shaper one 3, the polarizer one 4, the amplifier one 5 and the polarizer two 6 in turn, enters the SBS pulse compressor 7, and returns from the SBS pulse compressor 7 After passing through the polarization device 2 6, the amplifier 1 5, the polarization device 1 4, the shaper 2 8 and the amplifier 2 9 in turn, the light exits from the amplifier 2 9;

[0018] Polarizing device one 4 is used to transmit the laser light polarized...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is a further limitation of the solid-state laser with adjustable pulse width from 100 picoseconds to nanoseconds described in Embodiment 1. In this embodiment, the solid-state laser also includes a shaper 3 10 , nonlinear frequency converter 11 and beam splitter 12, the laser light emitted from amplifier two 9 passes through shaper three 10, nonlinear frequency converter 11 and beam splitter 12 in sequence, and then emerges from beam splitter 12.

[0022] After the laser light emitted from the amplifier two 9 passes through the shaper three 10, the nonlinear frequency converter 11 and the beam splitter 12 in sequence, the combined output of different laser wavelengths can be obtained.

specific Embodiment approach 3

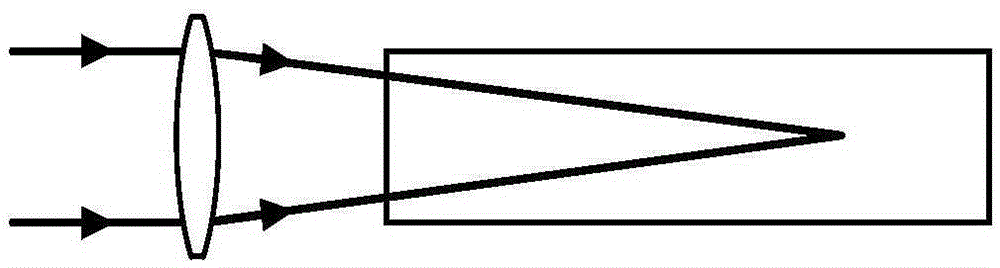

[0023] Specific Embodiment 3: This embodiment is a further limitation of the solid-state laser with adjustable pulse width from one hundred picoseconds to nanoseconds described in Embodiments 1 and 2. In this embodiment, the working substance of the SBS pulse compressor 7 gas, liquid or solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com