Intelligent bait casting machine and intelligent control system of bait casting machine

A technology of intelligent bait feeding and control system, applied in general control system, control/regulation system, computer control, etc., can solve the problems of high energy consumption and heavy workload of bait feeding, and achieve reduced energy consumption, flexible and accurate feeding range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

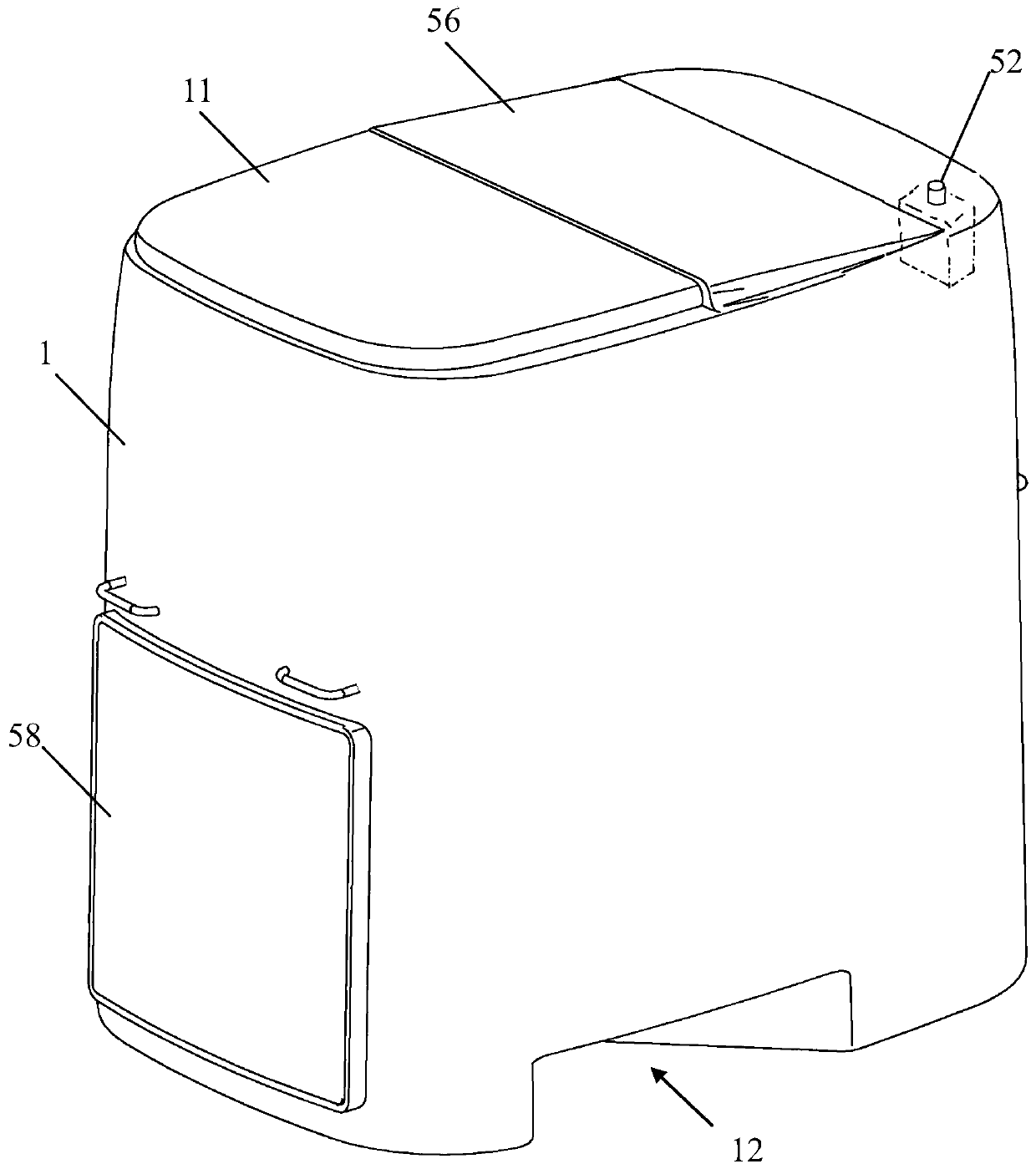

[0074] figure 1 It is a schematic diagram of the appearance of an intelligent bait casting machine according to a preferred embodiment of the present invention, which includes an outer shell 1, a bait bin 2, a material guide mechanism, a bait throwing mechanism and a control system.

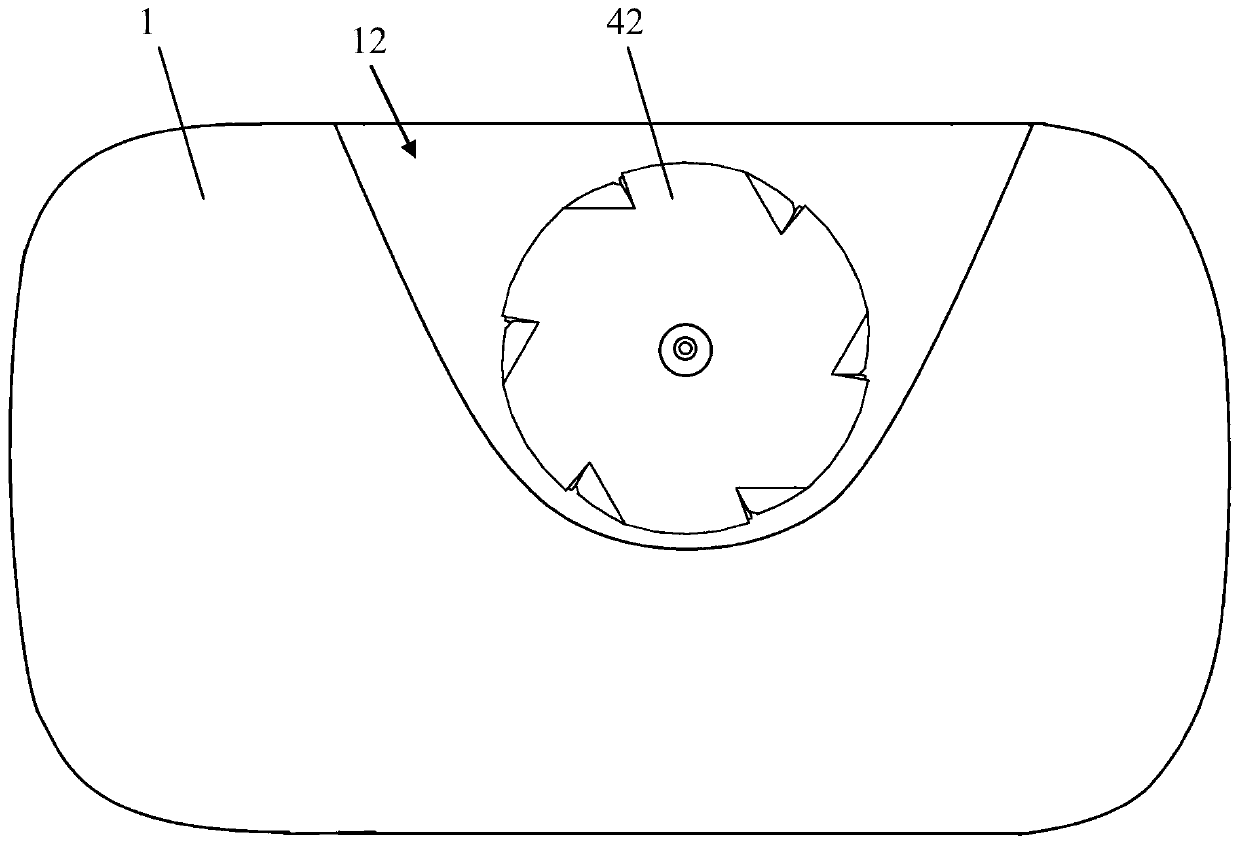

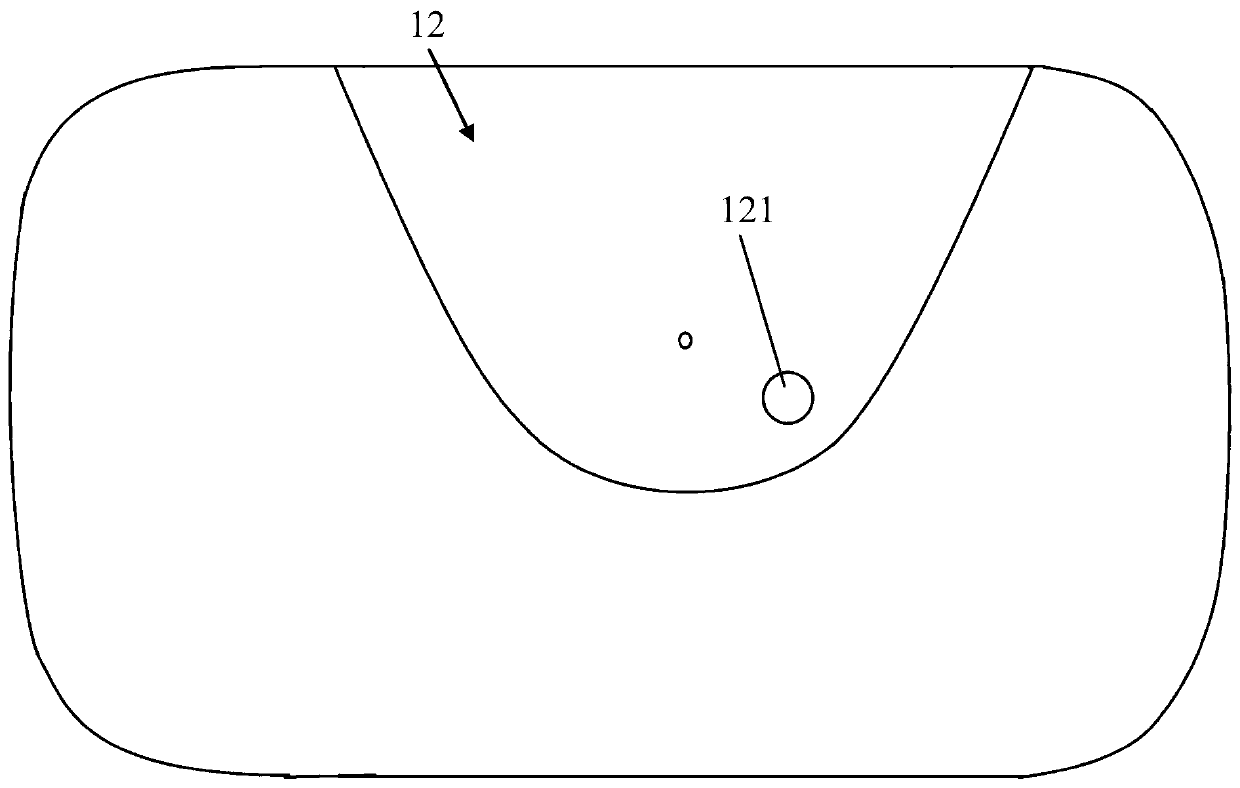

[0075]The top panel of the outer casing 1 is provided with a material feeding door 11 . The bottom plate of the outer casing 1 is provided with an upwardly recessed feeding groove 12, such as figure 2 with 3 As shown, the feeding groove 12 is provided with a first discharge port 121 . The opening on one side of the feeding groove 12 extends to the edge of the outer shell, the inner side of the feeding groove 12 away from the notch is arc-shaped, and the width of the feeding groove 12 gradually increases from the inner side to the notch. The setting of the feeding groove 12 enables the intelligent bait throwing machine to perform unidirectional bait throwing on one side, which can effectively ...

Embodiment 2

[0109] An intelligent control system for a bait-throwing machine, which can be used for the unified control of multiple bait-throwing machines with the structure described in Embodiment 1, which includes: several terminal power supplies, data collectors, controllers and Lora Node, and at least one Lora gateway, cloud and client, wherein, the terminal power supplies power for the controller and the bait feeder, the data collector is used to collect data related to the bait feeder, and the controller controls the bait feeder to turn on the bait feeder or Stop baiting, the controller and the Lora node are connected through the 485 communication protocol, the Lora node and the Lora gateway form a local area network through the Lora wireless transmission protocol, and the Lora gateway and the client use the wireless Internet protocol to perform data interaction with the cloud; the control system of the control system Methods include each feeder independently or synchronously with ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com