Transverse flux mutual inductance coupling linear switched reluctance motor

A switched reluctance motor, mutual inductance coupling technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as large normal force, improve power density, improve utilization, solve magnetic circuit interruption and magnetic The effect of road asymmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

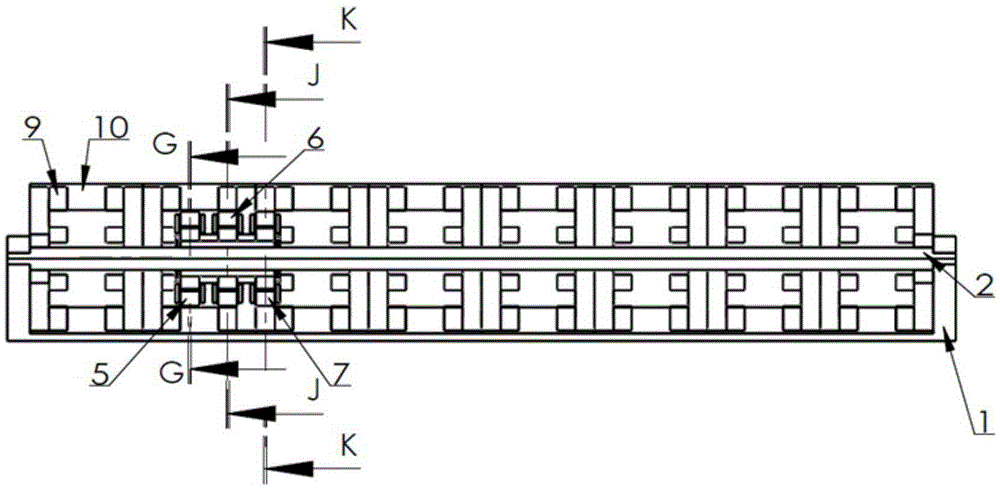

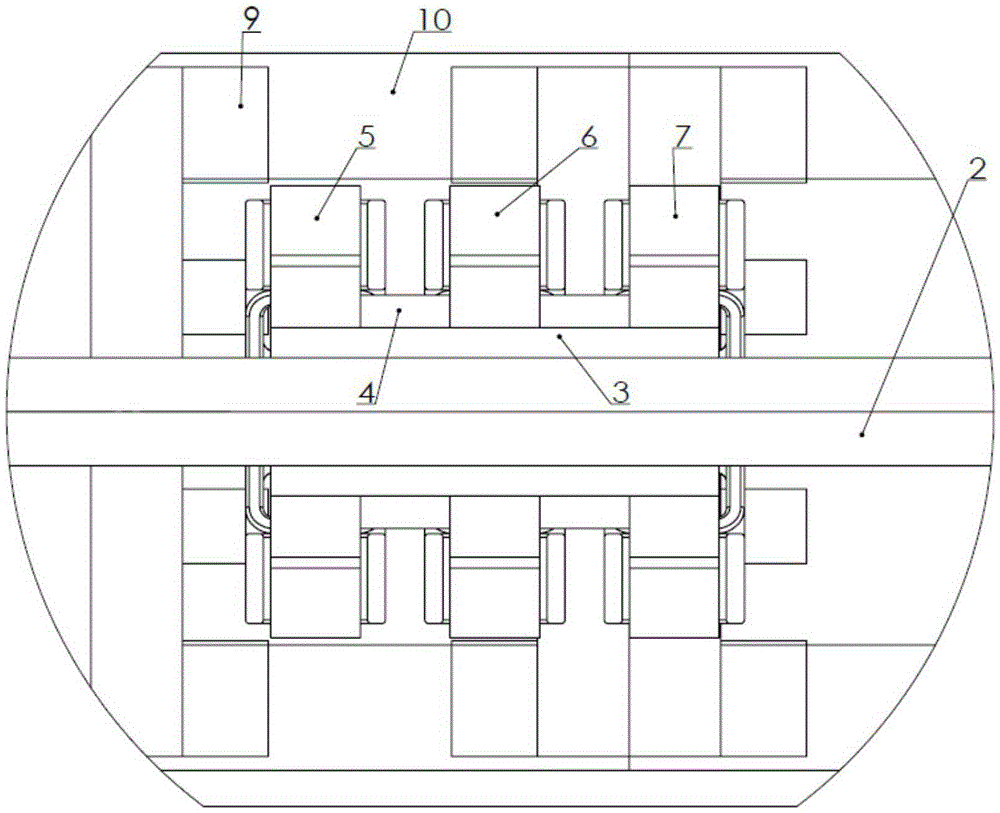

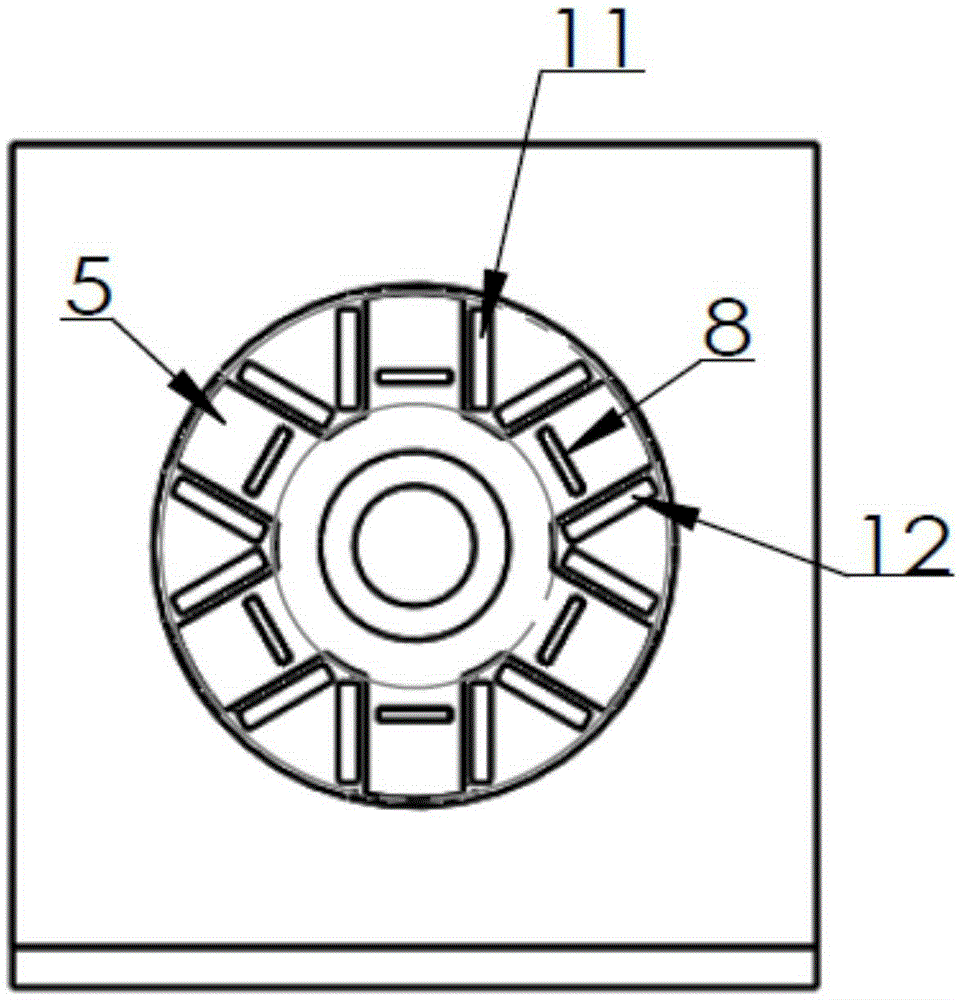

[0024] In this embodiment, the motor operates as an electric motor, the number of phases is 3, the number of stator blocks per cycle in the axial section is 2, and the number of mover blocks is 3. refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 . This embodiment includes a base 1, a shaft 2, a bearing 3, a shaft coupling 4, a stator, a mover, a permanent magnet 8 and mover windings arranged on the mover group. The stator includes several stator blocks 9 and stator sleeves 10, the stator blocks 9 are arranged at equal intervals in the axial direction, and include stator teeth, stator slots and stator yokes, and the stator sleeve 10 consists of several sleeves of the same size The sleeves are connected in the axial direction, and two stator blocks can be fixed in each sleeve; the mover is composed of mover one 5, mover two 6, mover three 7, permanent magnet 8 and mover windings (including A, B, C three-phase) structure, mover 1 5, mover 2 6, mover 3 7 ar...

Embodiment 2

[0029] The motor of this embodiment operates as a generator, and the specific structure is the same as that of Embodiment 1. During the operation of the generator, the DC excitation voltage is directly provided by the permanent magnet. figure 2 position, when the prime mover drives the mover to move in the axial direction opposite to the direction of the stator block 9, it overcomes the magnetic pull to do work, and the mechanical energy is converted into electrical energy. In principle, when the prime mover drives the mover to move in the direction shown in the figure, the mover windings output C and A phase currents and A and B phase currents outward in turn, continuously converting mechanical energy into electrical energy output.

[0030] In this embodiment, the number of stator blocks per cycle is 2, and the number of mover blocks is 3. However, in the specific implementation process, it is not limited to this, as long as the general law of pole-slot matching of the swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com