Thermo-photovoltaic power generation system based on heat pipe heat radiation platform

A thermal photovoltaic power generation, photovoltaic cell technology, applied in photovoltaic power generation, photovoltaic power stations, photovoltaic modules, etc., can solve the problems of unsuitable space vehicles, difficult to control the temperature of photovoltaic cells, etc., to achieve the effect of increasing temperature uniformity and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following combination Figure 1 ~ Figure 3 , a preferred embodiment of the present invention is described in detail.

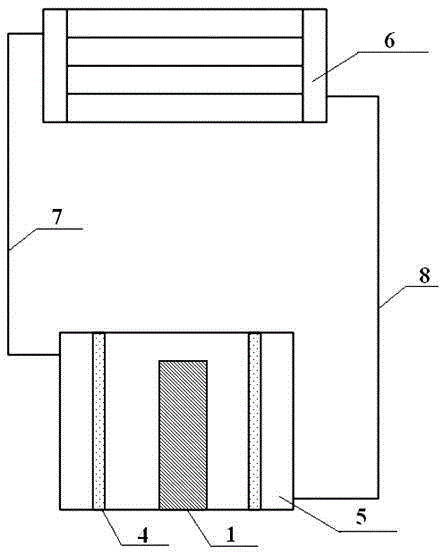

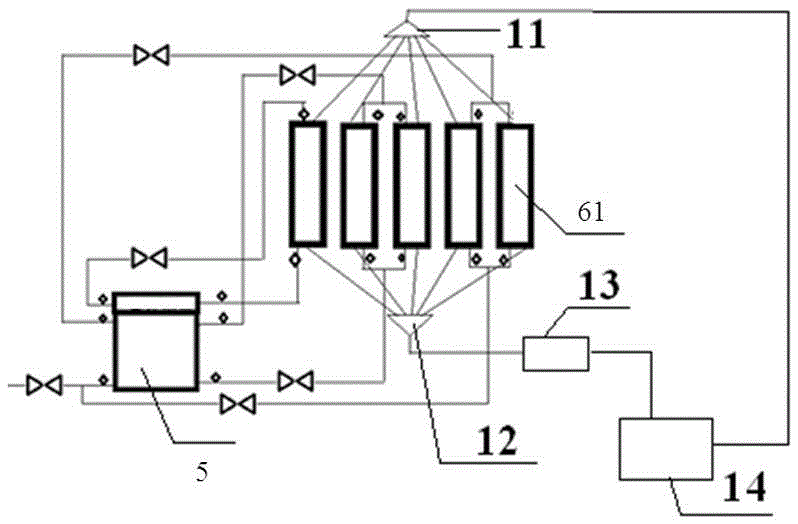

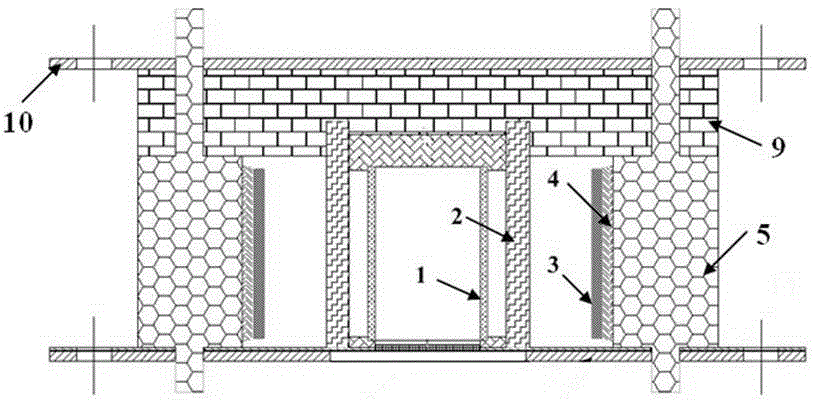

[0025] Such as figure 1 As shown, the thermal photovoltaic power generation system based on the heat pipe heat dissipation platform provided by the present invention includes: a heating module; a radiator 1, the radiator 1 is heated by the heating module, so that the radiator 1 emits infrared radiation to the outside Energy; a thermoelectric conversion module, which is arranged around the periphery of the radiator 1, receives the infrared radiation energy emitted by the radiator 1, and converts it into electrical energy output; a cooling module, which adopts a separate gravity flat heat pipe Perform heat exchange, take away the excess heat of the thermoelectric conversion module, and cool it; the cooling module includes: a heat pipe flat plate evaporator 5, which is arranged around the outside of the thermoelectric conversion module, and is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com