Filter element and a method for manufacturing a filter element

A filter element and filter process technology, applied in the direction of mobile filter element filter, filter separation, separation method, etc., can solve the problems of expensive replacement and increased operating time of filter plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles of the present invention can be used to dry or dehydrate fluid materials in any industrial process, especially in the ore and mining industries. In the embodiment described here, the material to be filtered is called slurry, but the embodiment of the present invention is not limited to this fluid material. The slurry can have a higher solid concentration, such as base metal concentrates, iron ore, chromite, ferrochromium, copper, gold, cobalt, nickel, zinc, lead, and pyrite. The following will illustrate exemplary embodiments of filter plates used for rotating vacuum disc filters, but the principle of the present invention can also be applied to filter media of other types of vacuum filters, such as rotating vacuum drum filters.

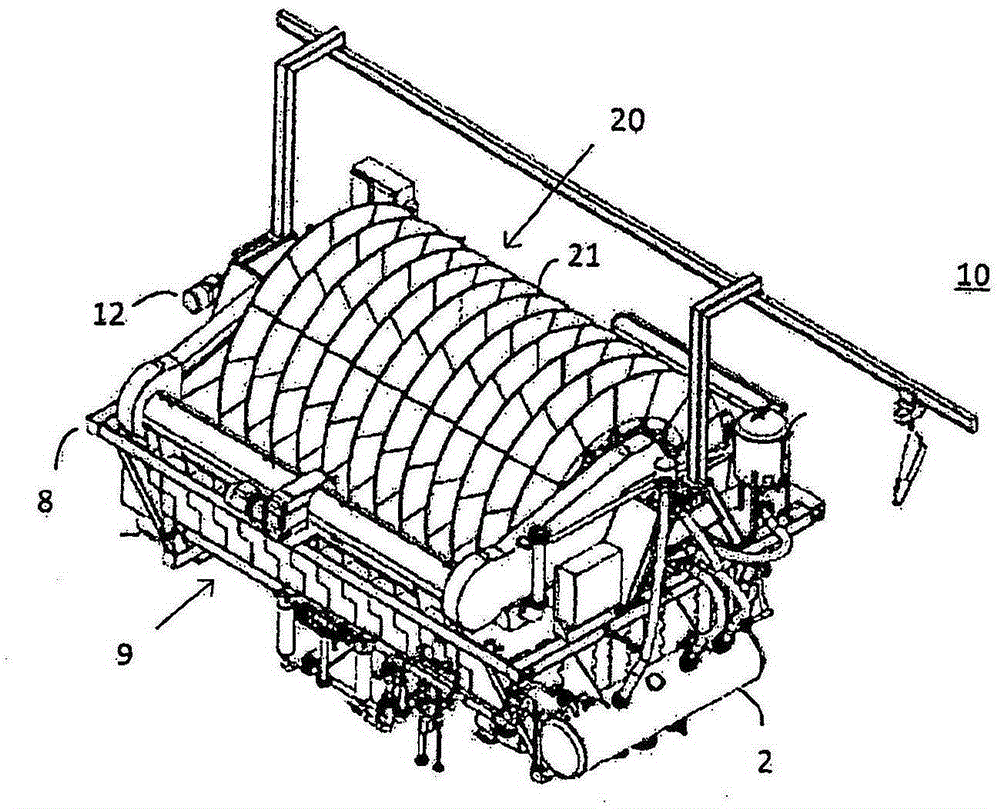

[0030] figure 1 It is a top perspective view showing an example disc filter device in which the filter plate according to the embodiment of the present invention can be used. The exemplary disc filter device 10 includes a cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com