Device for removing sulfur, fluorine, and dusts from glue gas

A dust removal device and defluorination technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of short reaction process, dust entry, dust removal, etc., to improve the reaction ability, facilitate maintenance, reduce dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

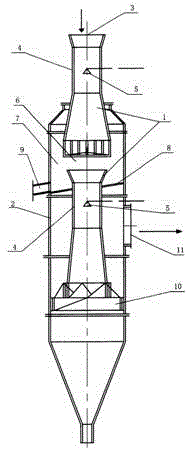

[0007] As shown in the figure, the flue gas desulfurization, defluorination and dust removal device of the present invention includes a reactor 1 with a two-stage structure and a casing 2 covering the periphery of the reactor; the flue gas enters the upper section of the reactor from the smoke inlet 3, and after shrinking Section 4 and the absorption liquid sprayed by the absorption liquid spraying device 5 undergo the first-stage absorption reaction, and then enter the dust removal chamber 7 from the disconnected part 6 of the two-stage reactor; in the dust removal chamber, most of the dust settles in the compartment at the bottom On the plate 8, when the dust accumulates to a certain amount, open the ash outlet 9 to clean it; the flue gas passing through the dust removal chamber enters the lower section of the reactor 1, and absorbs the dust sprayed by the contraction section 4 and the lower absorption liquid atomization spray device 5. The liquid undergoes the second-stage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com