A hydraulic turning tool for large rods

A rod and hydraulic technology, which is applied in the field of large-scale rod hydraulic turning tooling, can solve the problems of unguaranteed safety, time-consuming and labor-intensive turning, and surface damage of components, so as to improve the degree of mechanized operation, increase stability, and increase load bearing effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

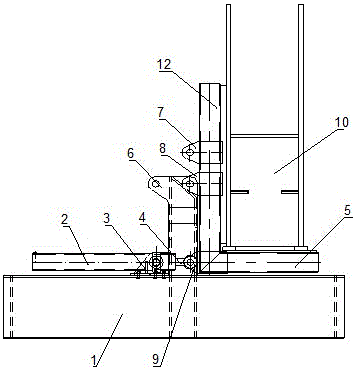

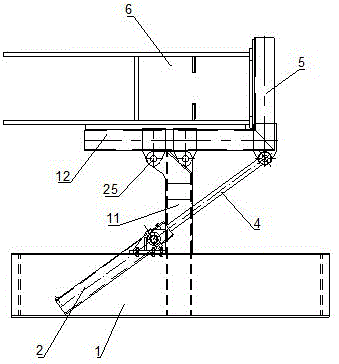

[0024] Such as figure 1 , figure 2 with image 3 As shown, the present invention discloses a hydraulic turnover tool for large rods, including a base 1, a support 11 vertically welded on the base 1, an oil cylinder 2 and an L-shaped support respectively arranged at both ends of the support 11.

[0025] Several pairs of supporting feet 13 are provided at both ends of the base 1 along the long axis direction, and reinforcing plates 14 are provided at both ends of the base 1 and the support 11 .

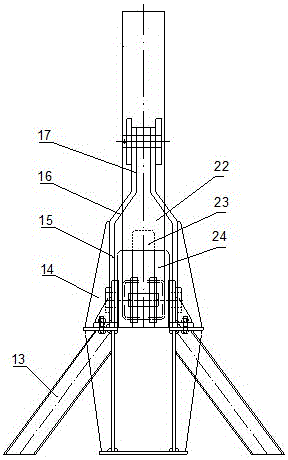

[0026] Such as Figure 4 As shown, the support 11 includes a pair of plates A21 arranged symmetrically along the long axis of the base 1, a plate B20 and a plate C18 perpendicular to the long axis of the base 1 and respectively welded on both sides of the pair of plates A21; The plate A21 is bent to form three sections, including the upper connecting plate A17, the lower connecting plate B15 parallel to the connecting plate A17, and the transition plate 16 in the middle. The connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com