Lightweight mechanical arm modular joint

A modular joint and robotic arm technology, applied in the field of robotics, can solve problems such as low joint control accuracy, inability to start work immediately, and unfavorable mass production. It achieves a large weight-to-load ratio and transmission accuracy, which is conducive to mass production and is convenient. The effect of disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

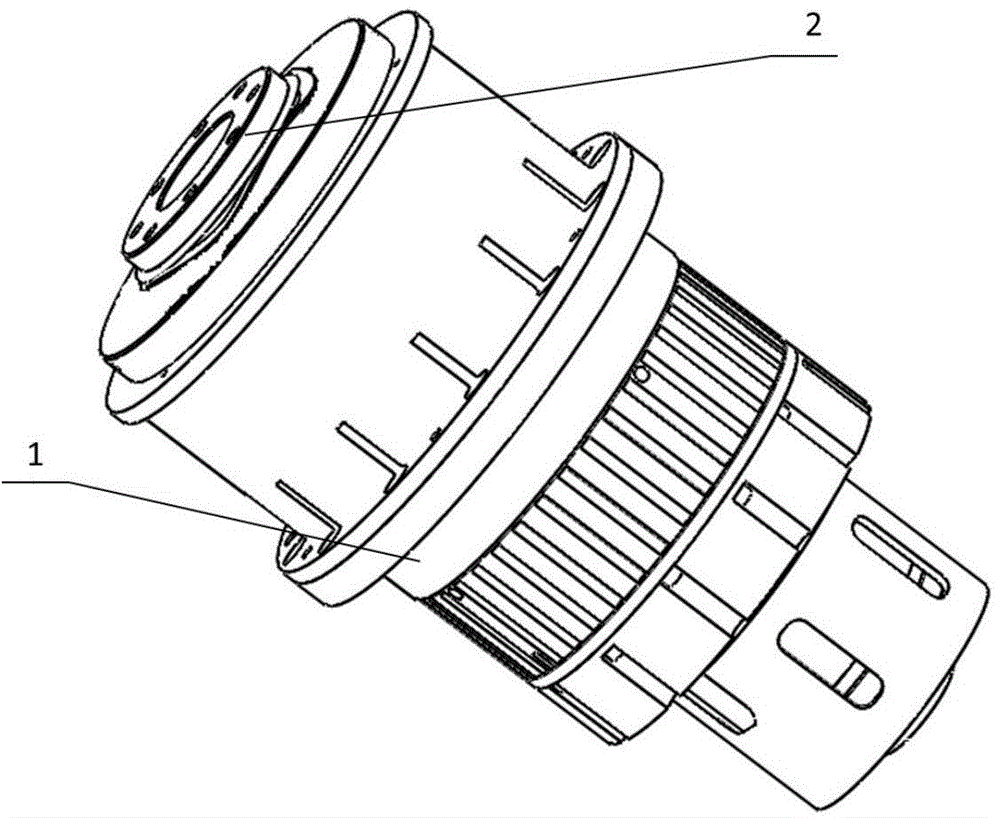

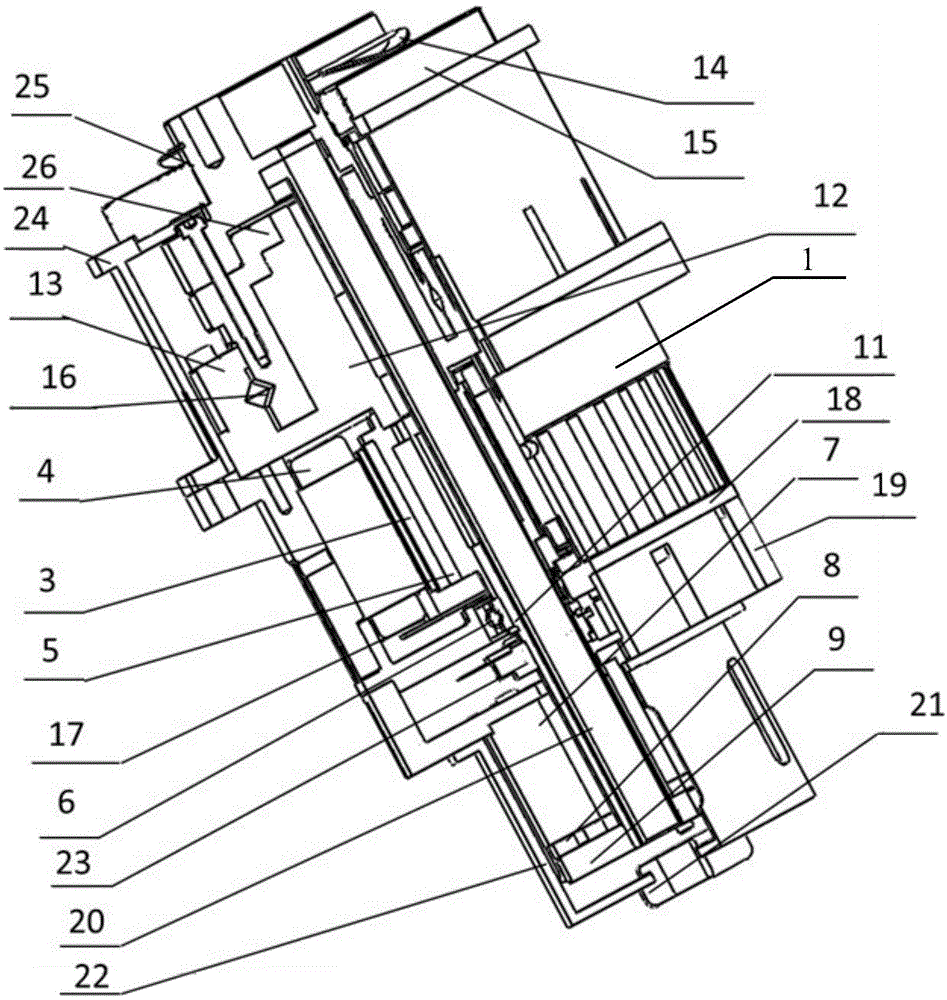

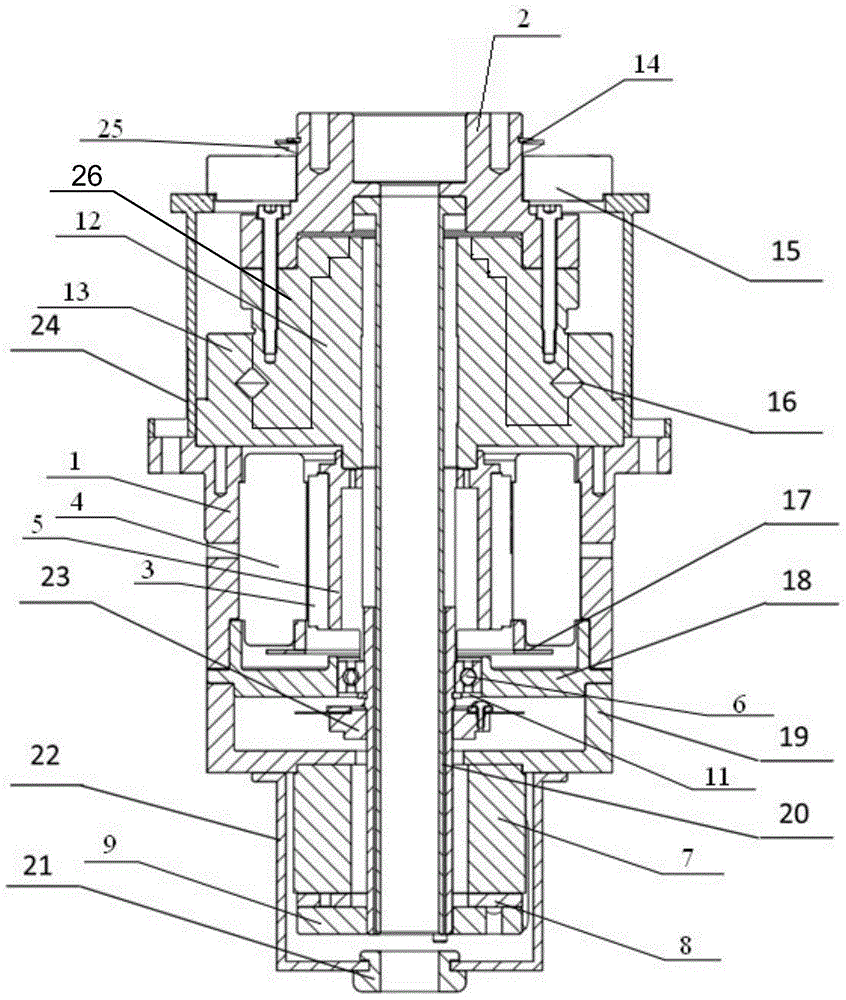

[0023] Such as figure 1 , 2 , 3, the lightweight mechanical arm modular joints include: drive assembly, joint assembly, electrical assembly,

[0024] The drive assembly includes hollow motor rotor 3, hollow motor stator 4, hollow motor shaft 5, high-speed motor bearing 6, hollow brake stator 7, hollow brake rotor 8, hollow brake rotor mounting flange 9, high-speed motor bearing retaining spring 11. The wave generator 12 of the harmonic reducer, and the flexible wheel 26 of the harmonic reducer.

[0025] The joint assembly includes modular joint mounting flange 1, modular joint output shaft 2, harmonic reducer steel wheel 13, cross roller bearing 16, hollow brake mounting flange 19, hollow cable tube 20, hollow bundle Wire harness 21, hollow wire harness installation flange 22.

[0026] The electrical assembly includes Hall sensor 17, photoelectric encoder 23, photoelectric encoder mount 18, absolute encoder 15, absolute encoder mounting flange 24, absolute encoder mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com