Flexible organic film capacitive sensor capable of sensing humidity and gas simultaneously and manufacturing method thereof

A capacitive sensor and organic thin film technology, applied in the direction of material capacitance, etc., can solve the problems of low sensor accuracy, easy to be affected by other conditions, and poor coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

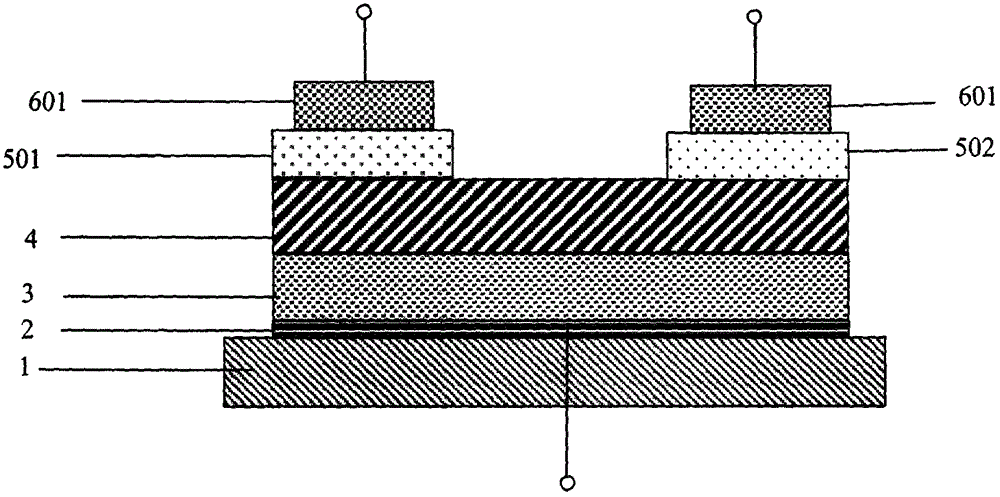

[0028] In this embodiment, a flexible organic thin film capacitive sensor is prepared according to the following steps:

[0029] 1) The substrate layer used is PET, and the lower electrode is made by magnetron sputtering method, and the ITO film is sputtered on the PET substrate; the ITO ceramic target material In 2 o 3 :SnO 2 =90:10wt.%, the purity is 99%. Before sputtering, the PET is cleaned with acetone, ethanol, deionized water and ultrasonic for 15 minutes. The method of preparing the lower electrode is magnetron sputtering, the work of magnetron sputtering The gas pressure was 2.5 pascals, the sputtering power was 140 watts, and the deposition time was 20 minutes.

[0030] 2) Prepare a humidity sensitive layer on the lower electrode by spin coating, dissolve polymethyl methacrylate in anisole (solution concentration is 50 mg / ml), spin coating speed is 6000 rpm, spin coating time for 45 seconds.

[0031] 3) Prepare a gas-sensitive layer by spin-coating on the humidit...

Embodiment 2

[0035] According to the same preparation method as in Example 1, only the methyl methacrylate in step 2) is changed to polyimide, and a flexible organic thin film capacitive sensor is obtained under the same preparation conditions as in the above-mentioned embodiment. The morphology and device performance are the same as in Example 1.

Embodiment 3

[0037] According to the same preparation method as in Example 1, only the propyl-trimethoxysilane in step 3) was changed to 3-diethylaminopropyl-trimethoxysilane, in the same preparation as in the above-mentioned examples The flexible organic thin film capacitive sensor was obtained under the same conditions, and the morphology and device performance of the sensor were the same as those in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap