Device and method for generating single-layer and/or dual-layer plasma photonic crystal

A plasma and photonic crystal technology, applied in the field of plasma application technology and optics, can solve the problem that the device can only produce single-layer plasma photonic crystals and only double-layer plasma photonic crystals, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

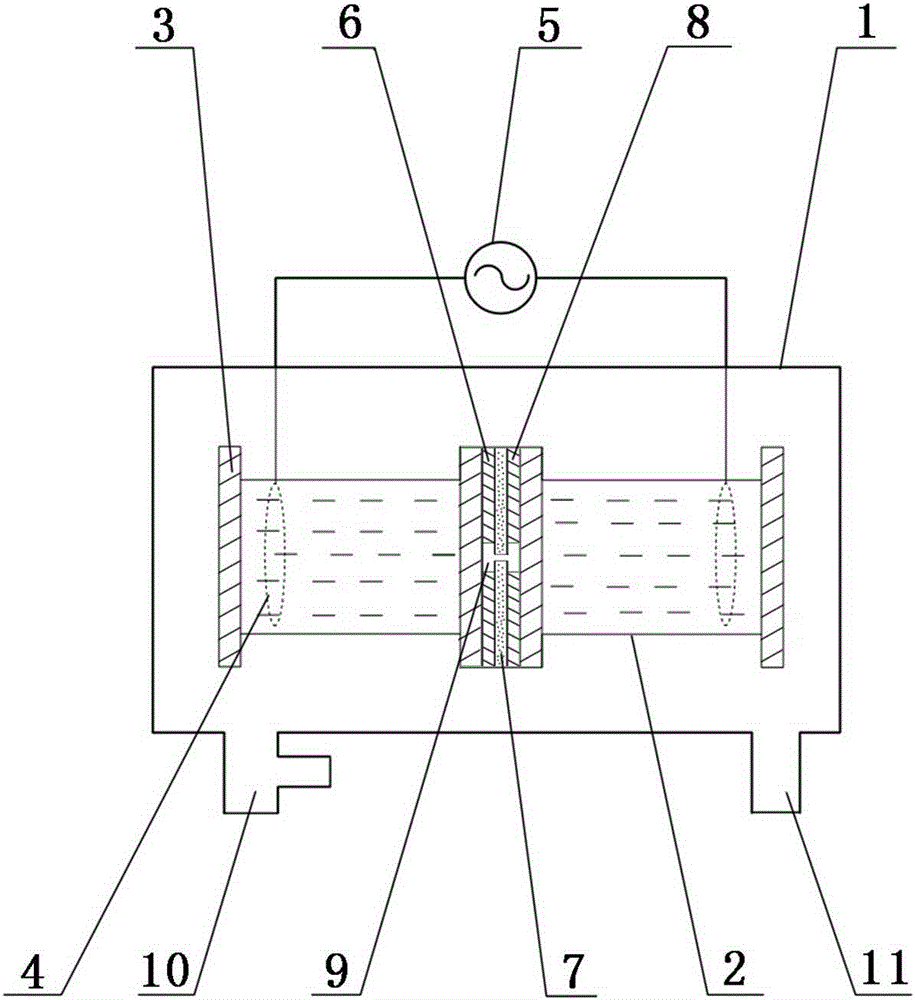

[0034] Such as figure 1 As shown, the device for producing single-layer and / or double-layer plasmonic photonic crystals provided by the present invention is to arrange two airtight dielectric containers symmetrically in a horizontal cylindrical vacuum reaction chamber 1, and in the airtight dielectric container Water is injected to form two water electrodes 2 . The two water electrodes 2 are electrically connected to a plasma generating power source 5 . The water electrode 2 is made of a plexiglass tube which is sealed by glass baffles 3 at both ends. The plexiglass tube is filled with water, and a copper ring 4 is set in the plexiglass tube. The two copper rings 4 are respectively electrically connected to the positive pole and the negative pole of the plasma generation power supply 5 outside the vacuum reaction chamber 1 through power lines. The thickness of the glass block 3 is between 0.5 mm and 3 mm.

[0035] Between the two water electrodes 2, there are left, middle a...

Embodiment 2

[0043] The method for producing single-layer and / or double-layer plasmonic photonic crystal provided by the present invention comprises the following steps:

[0044] a. A vacuum reaction chamber 1 is provided, an air inlet 10 and an air outlet 11 are provided on the wall of the vacuum reaction chamber 1 , and two water electrodes 2 are installed in the vacuum reaction chamber 1 . The water electrode 2 adopts a plexiglass tube sealed with glass baffles 3 on both sides and filled with water, and a built-in copper ring 4 is electrically connected to the plasma generating power supply 5 .

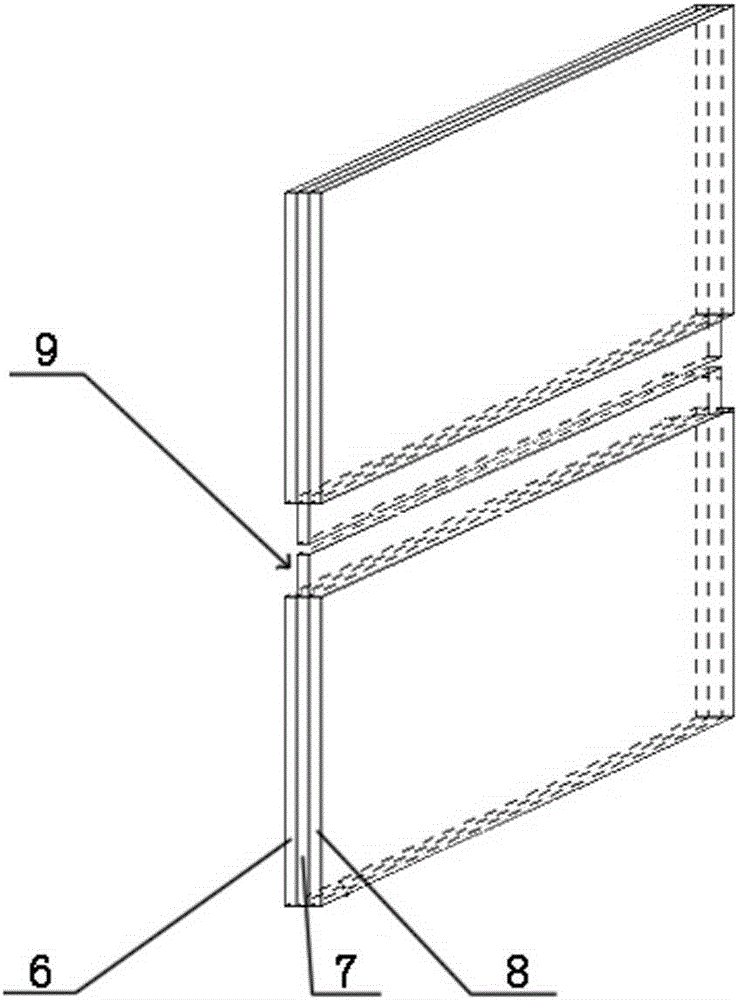

[0045] b. Between the two water electrodes 2, three layers of left, middle and right layers of glass are sequentially stacked and laminated. On the three layers of glass, a discharge gap 9 with a cavity cross-section in an H-shaped structure is formed, and the left, middle, and The three layers of glass on the right are perpendicular to the axis lines of the two water electrodes 2 respectively....

Embodiment 3

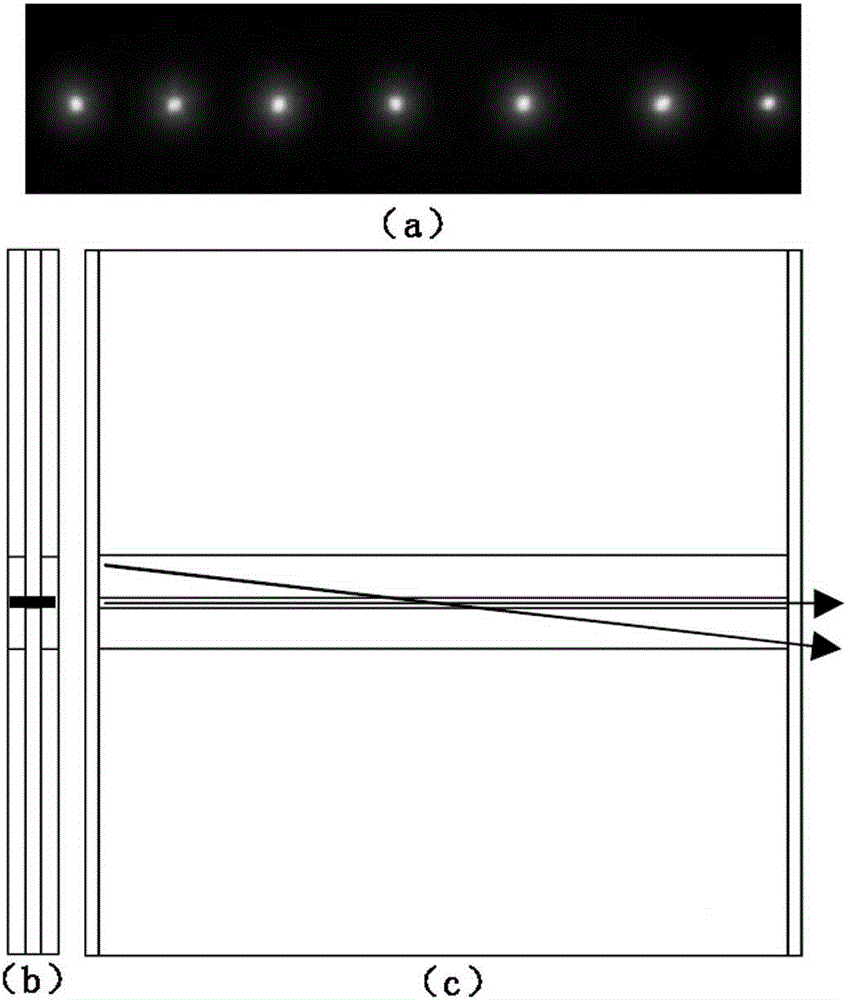

[0050] The present embodiment is compared with embodiment 2, and concrete experimental parameter is: the structure of three layers of glass is figure 2 In the structure shown, the thickness of the three layers of glass is 1.4mm; the length of the gap between the upper and lower glass in the left glass layer 6 is 80mm, and the width (that is, the distance between the upper and lower glass, or height) is 9mm The length of the gap between the upper and lower two sheets of glass in the middle glass layer 7 is 80mm, and the width is 1mm; the length of the gap between the upper and lower two sheets of glass in the right side glass layer 8 is 80mm, and the width is 9mm. The height of the single air gap in the middle of the discharge gap 9 is 1 mm, and the thickness is 4.2 mm (that is, the sum of the thicknesses of the three layers of glass). The upper and lower sides of the single air gap are double air gaps. For the double air gap on either side, the height of the two symmetrically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com