positive temperature coefficient element

A positive temperature coefficient and component technology, applied in the direction of resistors with positive temperature coefficients, electrical components, non-adjustable metal resistors, etc., can solve the problem of reducing the PTC trigger temperature, no teaching, no teaching low molecular weight organic compound melting temperature concentration to achieve the effect of high maintenance current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above and other technical contents, features and advantages of the present invention more comprehensible, the following specifically cites relevant embodiments, together with the accompanying drawings, for a detailed description as follows.

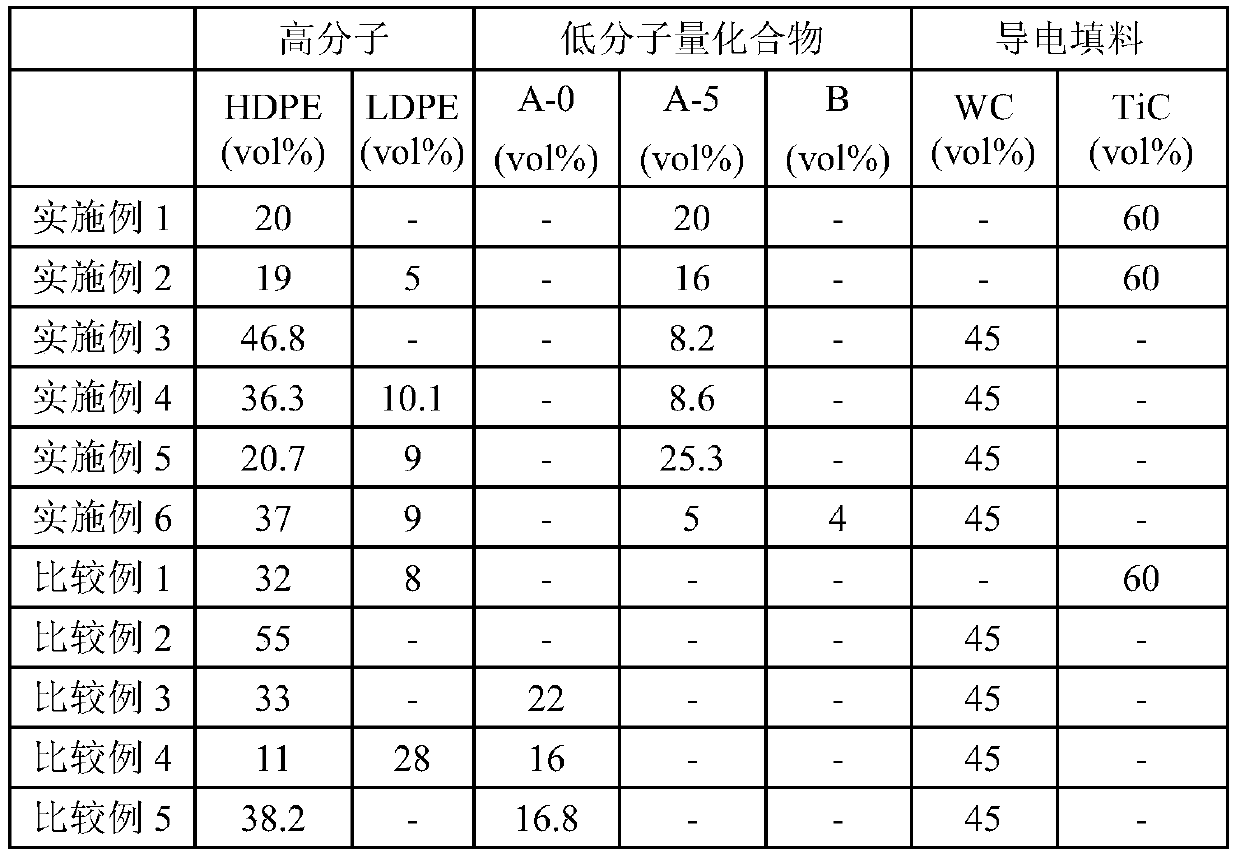

[0029] The structure of the PTC element of the present invention is exemplified as figure 1The PTC element 10 includes two electrode layers 12 and a PTC material layer 11 stacked between the two electrode layers 12 . The PTC material layer 11 includes crystalline high molecular polymer, conductive ceramic filler and crystalline low molecular weight organic compound. The crystalline high molecular polymer is used as the base material of the PTC material layer 11, and the conductive ceramic filler and the crystalline low molecular weight organic compound are uniformly dispersed in the base material formed by the crystalline high molecular polymer. The crystallinity of crystalline low-molecular-weight organic com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com