High-Mach-number low-temperature spray tube for HF/DF chemical laser

A high Mach number, chemical laser technology, used in laser parts and other directions, can solve the problems of increased working pressure of the combustion chamber, unfavorable light output medium gain, loss of kinetic energy of the main nozzle, etc., and achieves improved gain, simple processing, and optical cavity temperature. and low pressure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

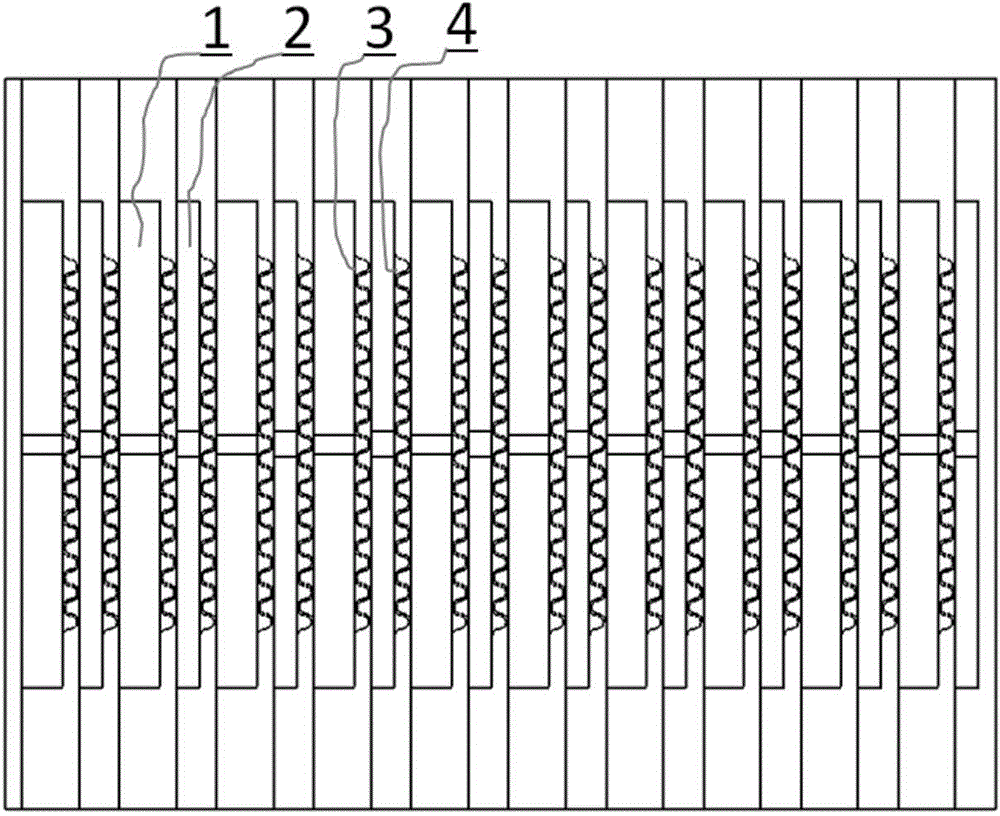

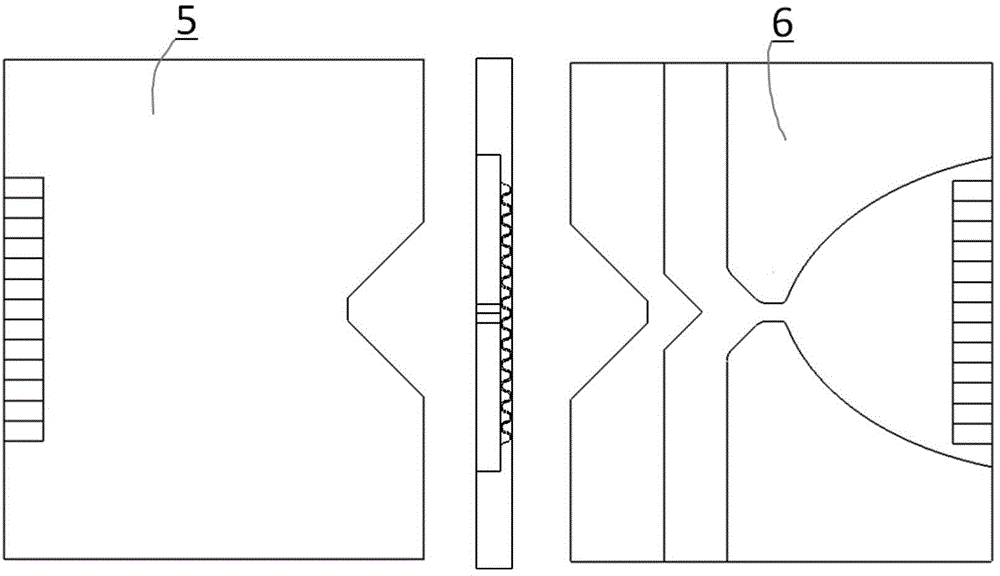

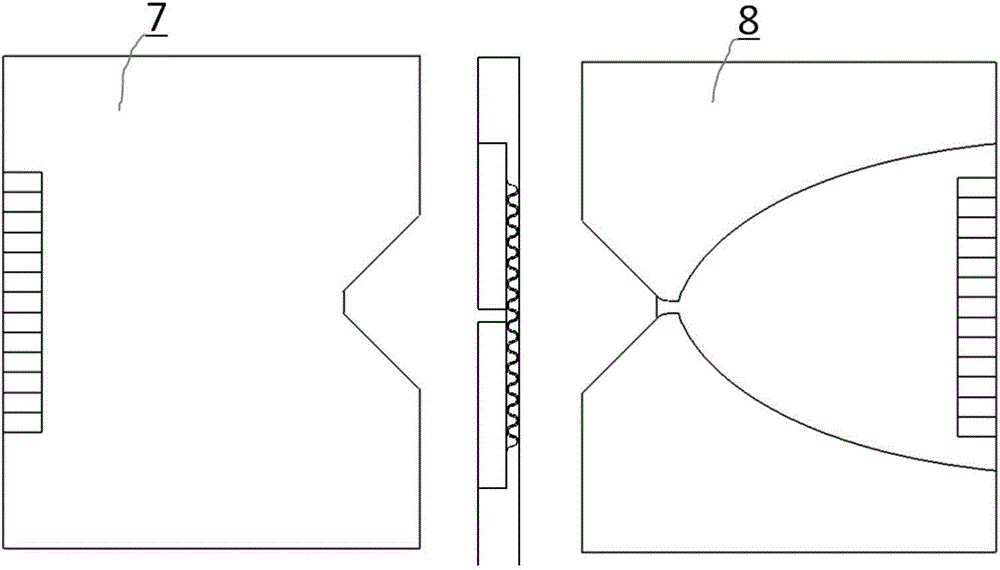

[0028] According to the design concept of the present invention, the following nozzles have been designed, the integral nozzle, the auxiliary nozzle assembly and the main nozzle assembly such as Figure 1-3 Shown:

[0029] A high Mach number cryogenic nozzle for HF / DF chemical laser, including a main nozzle unit and a sub-nozzle unit, both of which are typical two-dimensional slit Rafal nozzles , the inlet of the main nozzle unit is connected to the outlet of the combustion chamber, the outlet of the main nozzle unit is connected to the optical cavity, the inlet of the auxiliary nozzle unit is connected to the H2 gas storage chamber, and the outlet of the auxiliary nozzle unit is connected to the optical cavity; In the expansion direction of the expansion section of the unit and the sub-nozzle unit, the main nozzle unit and the sub-nozzle unit are arranged parallel to each other and staggered sequentially to form the whole nozzle.

[0030] The ratio of the height of the expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com