Semiconductor laser stack array structure

A semiconductor and laser technology, applied in the field of large-channel semiconductor laser stacked array structure, can solve the problems of difficulty in ensuring good heat dissipation, the influence of the normal operation of the stacked array, and the inability to achieve heat dissipation of the stacked array, so as to ensure long-term high reliability and stable operation, good Heat dissipation and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

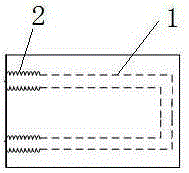

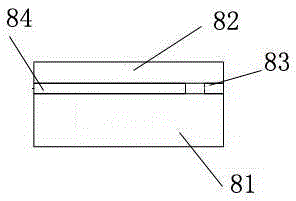

[0027] Attached below Figure 1~7 The present invention will be further described in detail with specific embodiments.

[0028] The semiconductor laser stack structure provided by the present invention includes a semiconductor laser array module. The semiconductor laser array module includes a P electrode and an N electrode, and an insulating sheet and an array chip are packaged between the P electrode and the N electrode. The P surface electrode thickness of the semiconductor laser array module is generally 2-8mm, and its P electrode and N electrode are usually made of oxygen-free copper.

[0029] The semiconductor laser array structure of the present invention also includes a water tank module. Two completely isolated first water tanks and second water tanks are arranged in the water tank module. One end of the first water tank and the second water tank is respectively connected with a copper pipe, and then through the copper pipe The water inlet and outlet connected to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com