Aluminum alloy plate for magnetic disk, aluminum alloy blank for magnetic disk, and aluminum alloy substrate for magnetic disk

A technology for aluminum alloy plates and magnetic disks, applied in the direction of disk-shaped carrier, magnetic recording, magnetic recording layer, etc., can solve the problem of inability to form films, and achieve the effect of excellent yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

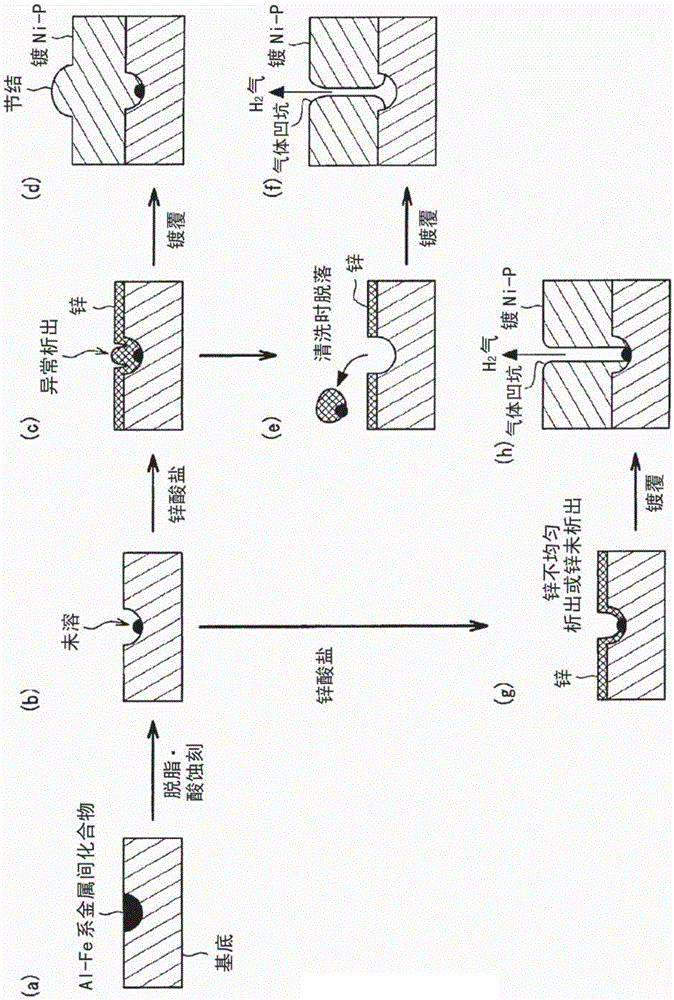

Method used

Image

Examples

Embodiment

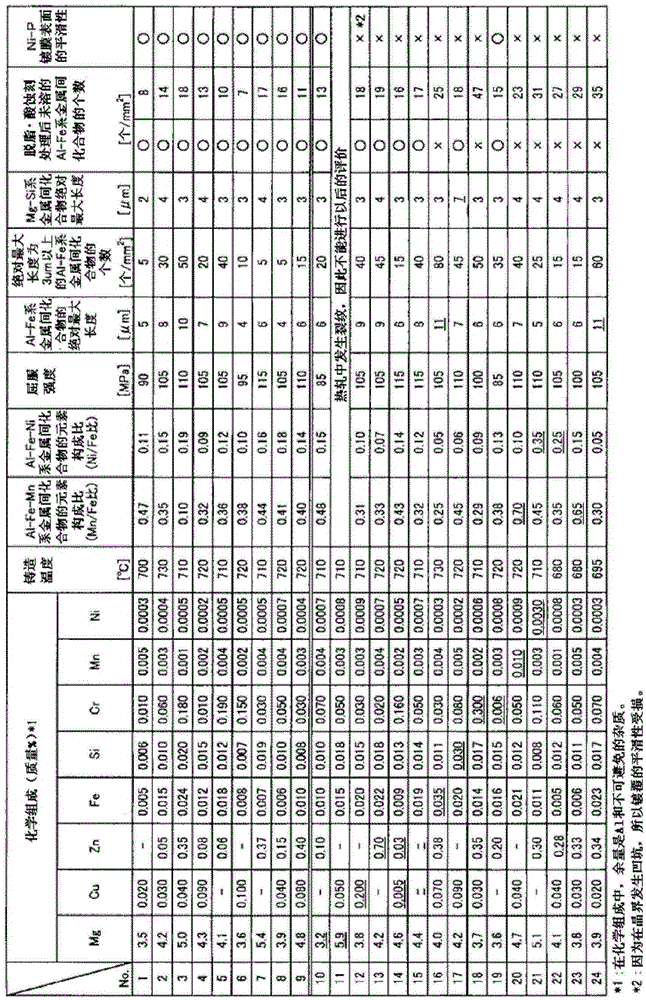

[0120] Next, the contents of the present invention will be specifically described with reference to Examples that exhibit the effects of the present invention and Comparative Examples that do not.

[0121] First, the material was melted at 700° C., the components were adjusted so as to have the chemical compositions shown in No. 1 to 24 in Table 1, and ingots were cast at the casting temperatures shown in Table 1. Next, surface cutting was performed to remove the segregation layer on the surface of the ingot, and a homogenization heat treatment was performed at 540° C. for 8 hours. Thereafter, hot rolling was immediately performed to produce a hot-rolled sheet having a thickness of 3 mm. Then, this hot-rolled sheet was cold-rolled to manufacture a cold-rolled sheet having a thickness of 1.0 mm.

[0122] This cold-rolled sheet (Al alloy sheet) was punched into a ring shape with an outer diameter of 95 mm and an inner diameter of 25 mm, stacked 20 sheets, annealed at 320°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com