Non-aqueous electrolyte secondary cell

一种非水电解质、二次电池的技术,应用在二次电池、电池、电池电极等方向,能够解决安全性降低、电池特性降低等问题,达到安全性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

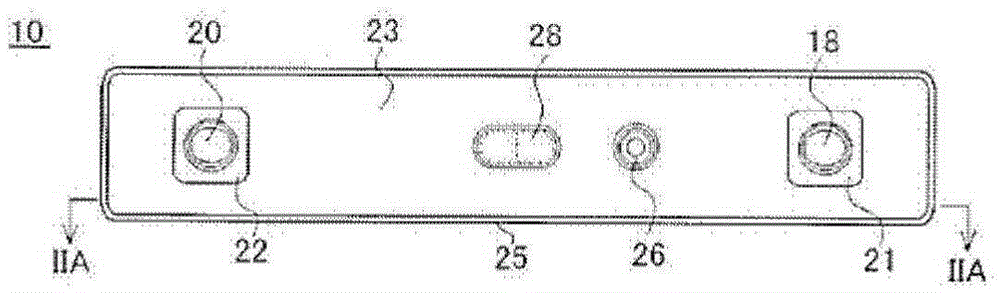

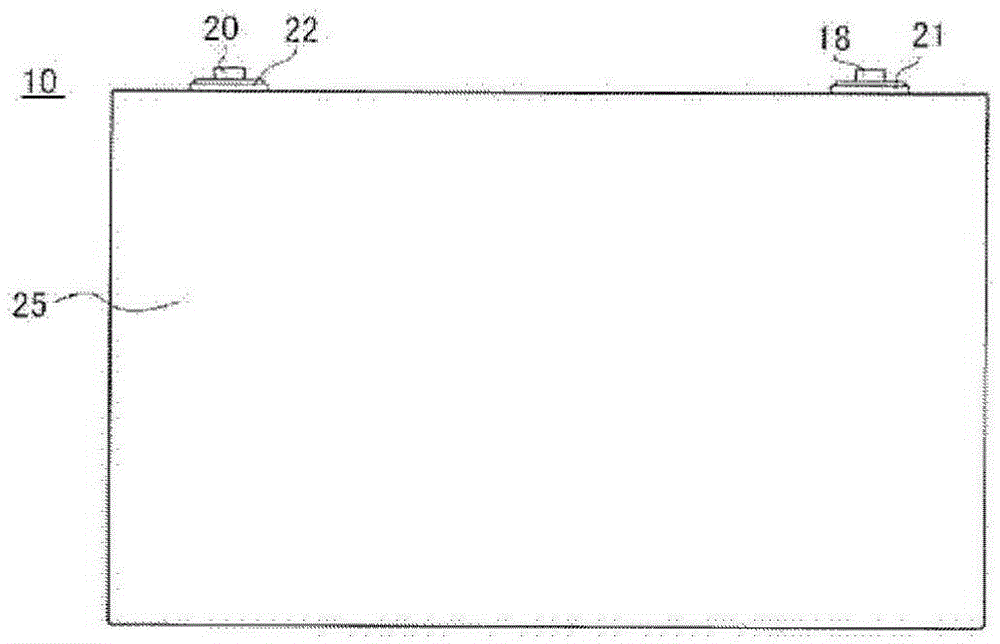

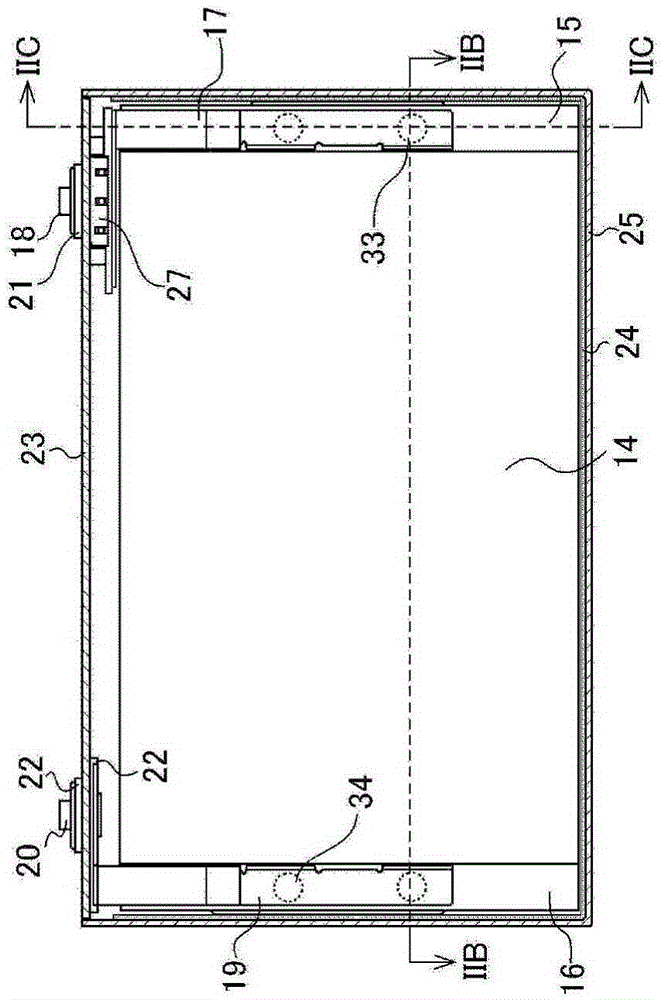

[0040] First, the non-aqueous electrolyte secondary battery of the embodiment will be described using FIGS. 1 to 4. As shown in FIG. 4, this non-aqueous electrolyte secondary battery 10 has a flat wound electrode body 14 wound in a state where the positive electrode plate 11 and the negative electrode plate 12 are insulated from each other with a separator 13 interposed therebetween. The outermost side of the flat wound electrode body 14 is covered by the separator 13, and the negative electrode plate 12 is on the outer peripheral side compared to the positive electrode plate 11.

[0041] Positive plate 11 such as Figure 3A As shown, on both sides of a positive electrode core body composed of aluminum or aluminum alloy foil with a thickness of about 10 to 20 μm, there are formed in a state where one end of the positive electrode core body along the width direction is exposed in a strip shape. Positive electrode mixture layer 11a. The portion of the positive electrode core expos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com