Non-combustion low-temperature top-speed heating device and cigarette case thereof

A heating device and non-combustion technology, which is applied in tobacco, smoker’s products, applications, etc., can solve the problems of affecting the service life of the heating sheet, the heating rate is not fast enough, and the temperature distribution is uneven, so as to overcome the heating rate and temperature. The effect of small difference and uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

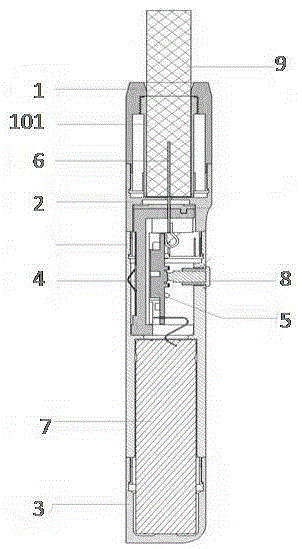

[0044] Such as figure 1 As shown, a non-combustion low-temperature and extremely fast heating device includes a cigarette holder 1, a cigarette rod 2 and a battery compartment 3 connected in sequence. The cigarette holder 1 has a cavity 101 for inserting a cigarette 9, and the cigarette rod 2 is provided with a fixing frame 4. The controller in the fixed frame 4 and the double-sided ceramic heating sheet 6 that can be inserted into the cigarette, the controller is a PCB control board 5, the PCB control board 5 is provided with a switch 8, the double-sided ceramic heating sheet 6 and the fixed frame 4 One end close to the cavity of the cigarette holder is connected, and the double-sided ceramic heating sheet is opposite to the cavity. The battery compartment 3 is provided with a detachable and replaceable rechargeable battery 7, and the PCB control board 5 is connected with the rechargeable battery.

[0045] The shells of the cigarette holder 1, the cigarette rod 2 and the bat...

Embodiment 2

[0060] The non-combustion low-temperature and extremely fast heating device described in this embodiment has the same components and connection methods as in Embodiment 1. The difference from Embodiment 1 is that the double-sided ceramic heating sheet is prepared by the following method:

[0061] Prepare electronic paste:

[0062] S1. Mix 12.0g of ferromanganese alloy powder, 15.0g of molybdenum powder, 20.0g of palladium powder, 1.0g of kaolin, 10.0g of talcum powder, and 20.0g of titanium platinum powder, then add 1.0g of nano-carbon powder, stir and mix to obtain a mixed powder ; The ferromanganese alloy is composed of the following elements by mass percentage: 70.0% manganese, 15.0% iron, and 10.0% silicon.

[0063] S2. At 60-80°C, mix terpineol 16.0g, castor oil 4.0g, and hydrogenated castor oil 1.0g to obtain a solvent;

[0064] S3. Slowly add the mixed powder into the solvent and stir for 1-3 hours to obtain the electronic paste.

[0065] Other preparation method step...

Embodiment 3

[0069] The non-combustion low-temperature and extremely fast heating device described in this embodiment has the same components and connection methods as in Embodiment 1. The difference from Embodiment 1 is that the double-sided ceramic heating sheet is prepared by the following method:

[0070] S1. Mix 18.0g of ferromanganese alloy powder, 8.0g of molybdenum powder, 10.0g of palladium powder, 5.0g of kaolin, 3.0g of talcum powder, and 34.0g of titanium platinum powder, then add 5.0g of nano-carbon powder, stir and mix to obtain a mixed powder ; The ferromanganese alloy is composed of the following elements by mass percentage: 70.0% manganese, 15.0% iron, and 10.0% silicon.

[0071] S2. At 60-80°C, mix 12.0 g of terpineol, 4.0 g of castor oil, and 1.0 g of hydrogenated castor oil to obtain a solvent;

[0072] S3. Slowly add the mixed powder into the solvent and stir for 1-3 hours to obtain the electronic paste.

[0073] Other preparation method steps are identical with embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com