A pressing device suitable for LED lamp heat sink and its realization method

A pressing device and LED lamp technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of only pressing one group or two groups at a time, and achieve high safety, reasonable power design, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

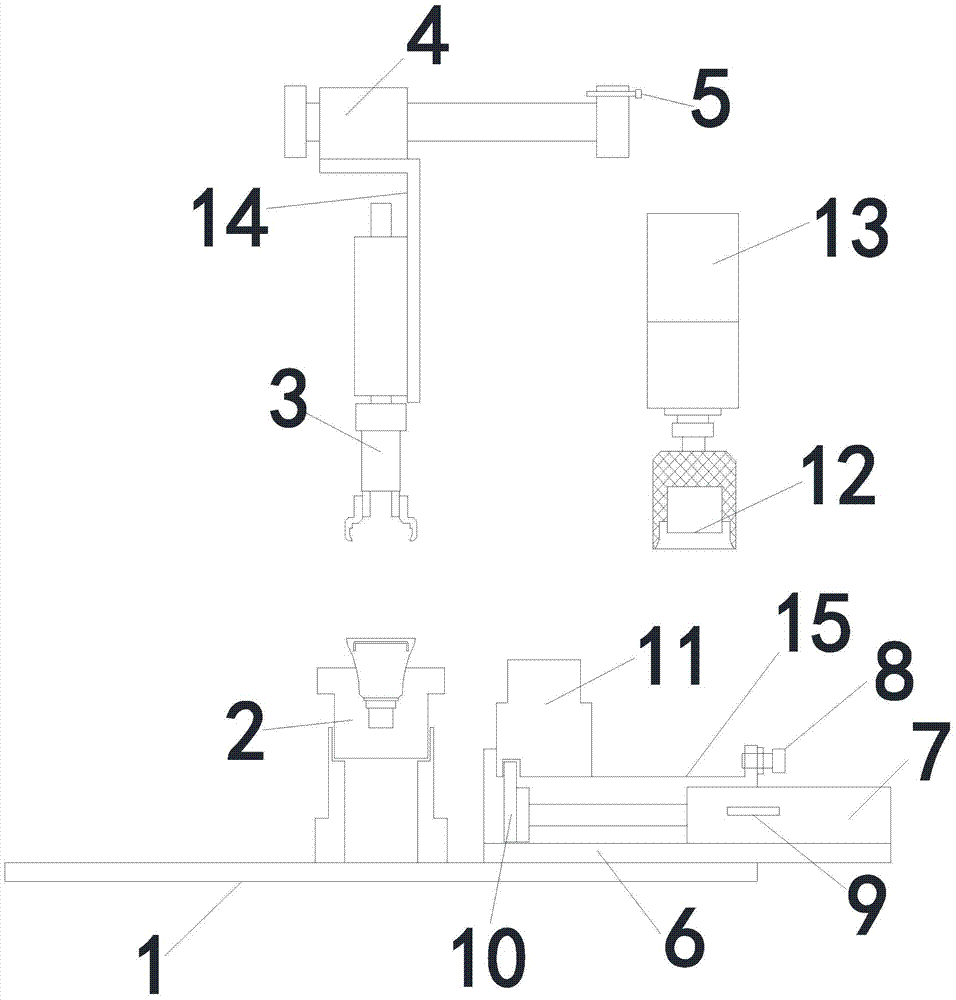

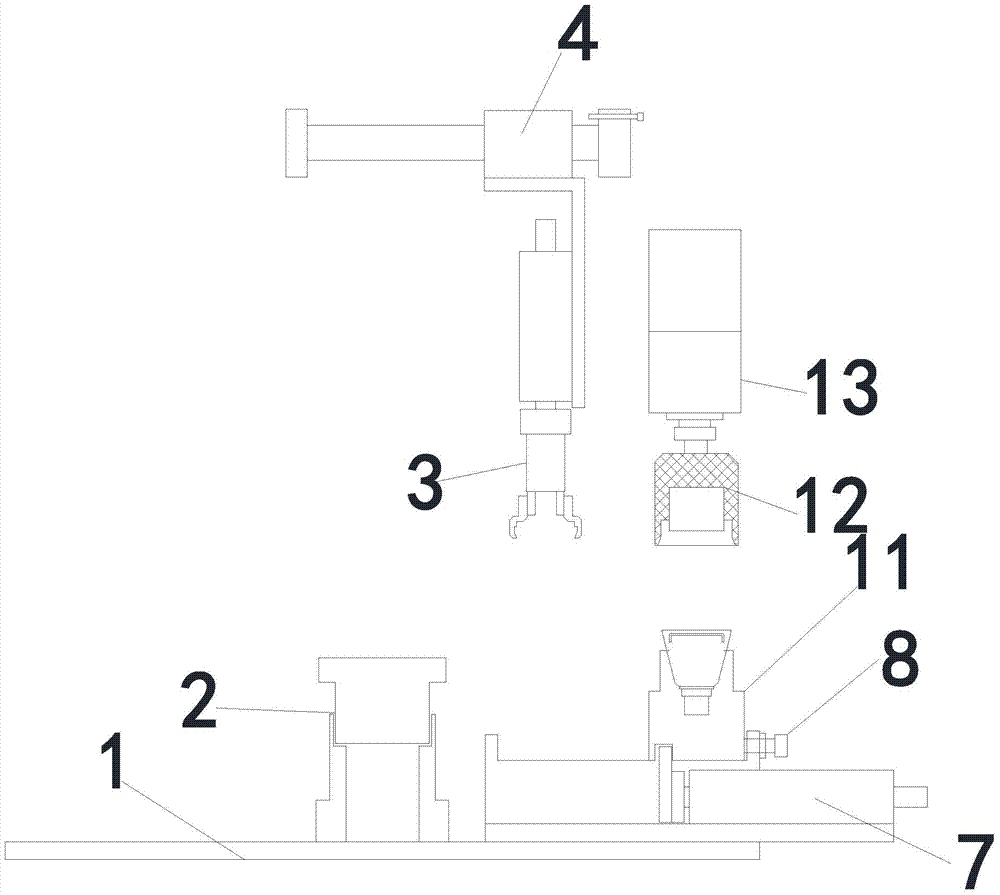

[0039] Such as Figure 1~2 As shown, a pressing device suitable for heat sinks of LED lamps includes an automatic conveyor belt, on which several carriers are arranged, and an execution cylinder is installed on the side plate of the automatic conveyor belt to block and release the carriers. There is a manipulator, and the manipulator is connected with the cylinder of the slide table. The end of the cylinder of the slide table is provided with a first limit screw. There is a second limit screw, and a position sensor is installed on the side of the moving cylinder. The telescopic end of the moving cylinder is connected to the short plate. The head of the short plate goes deep into the groove under the supporting fixture. Tool, the lower pressure fixture is connected with the force cylinder.

[0040] The carrier in this embodiment is a five-connected carrier; the slide cylinder is connected to the manipulator through the manipulator connecting plate.

[0041] This embodiment al...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 lies in that the length of the head of the short plate in this embodiment is 12 mm, and the depth of the groove is 12.5 mm.

Embodiment 3

[0061] The difference between this embodiment and Embodiment 1 is that the length of the head of the short board in this embodiment is 10mm, and the depth of the groove is 10.5mm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com