Method for continuously efficiently extracting parthenolide from southern magnolia leaves

A technology of parthenolide and Magnolia grandiflora is applied in the field of extracting active ingredients to achieve the effects of high content of active ingredients, reduced loss and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

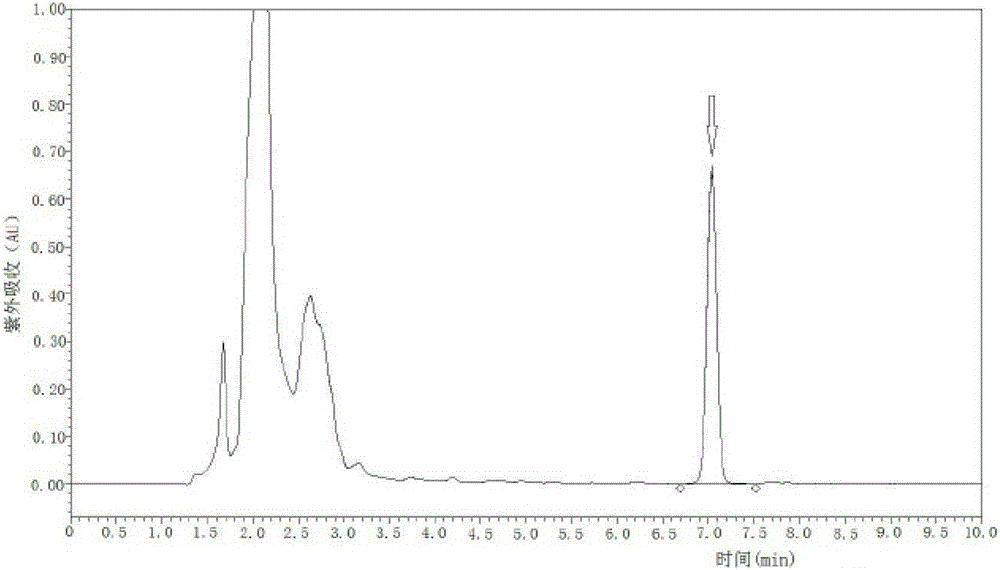

Embodiment 1

[0042] Take 4 extraction tanks in series. Take by weighing 50kg Guangyulan fresh leaves and beating broken, leaf slurry is divided into 4 parts, each part 12.5kg, is placed in 25L volume concentration respectively in the methanol of 90%, cold immersion 20h under normal temperature, this 4 parts after cold immersion Put the leaf pulp into the four extraction tanks respectively, add 100L of methanol with a volume concentration of 90% to the first extraction tank, heat it to 65°C-70°C, keep the temperature, and extract the extract from the first extraction tank after 25 minutes. Put the liquid into the second extraction tank, heat it to 65°C-70°C, and maintain the temperature. After 25 minutes, extract the extract from the second extraction tank into the third extraction tank, heat it to 65°C-70°C, and maintain the temperature After 25 minutes, extract the extract from the third extraction tank into the fourth extraction tank, heat it to 65°C-70°C, and keep the temperature for 25...

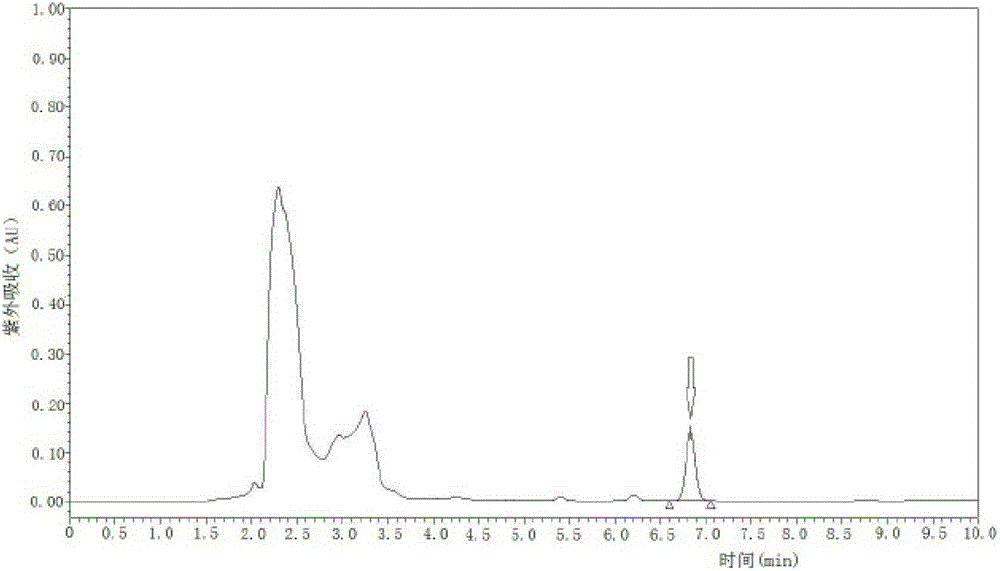

Embodiment 2

[0046] Take 5 extraction tanks in series. Take by weighing 50kg Magnolia magnate fresh leaves and make a pulp and break it, and the leaf slurry is divided into 5 parts, each part of 10kg, and placed in 20L of ethanol with a volume concentration of 95%, cold soaking at normal temperature for 12h, and 5 parts of leaves after cold soaking Put the slurry into the five extraction tanks respectively, add 80L of ethanol with a volume concentration of 95% to the first extraction tank, heat to 65°C-70°C, keep the temperature, and extract the extract from the first extraction tank after 30 minutes into the second extraction tank, heated to 65°C-70°C, and maintained at this temperature, after 30 minutes, extract the extract from the second extraction tank into the third extraction tank, heated to 65°C-70°C, and maintained at this temperature, After 30 minutes, extract the extract from the third extraction tank into the fourth extraction tank, heat it to 65°C-70°C, and keep the temperatur...

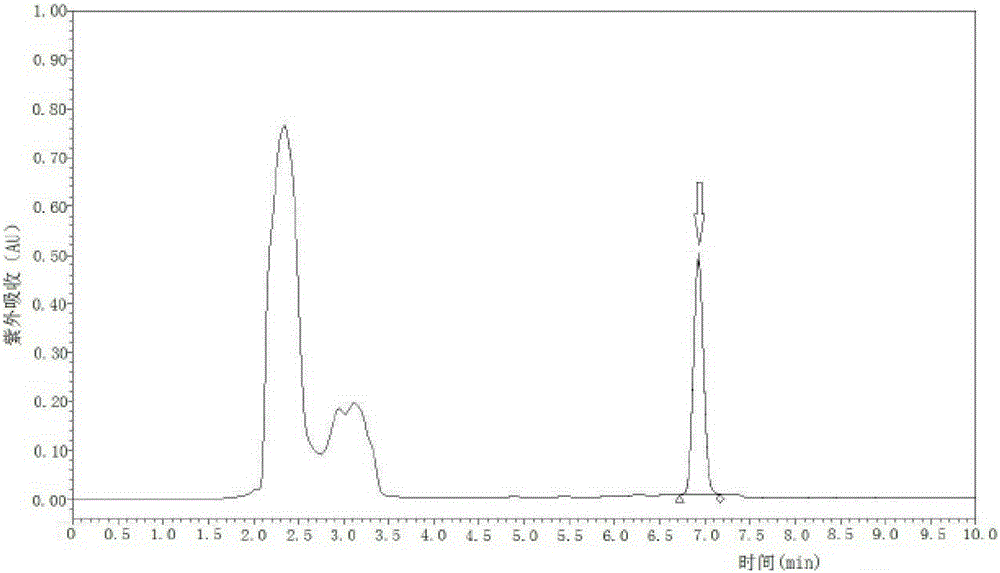

Embodiment 3

[0050]Take 3 extraction tanks in series. Take by weighing 51kg Magnolia magnanimum fresh leaves and beating broken, leaf slurry is divided into 3 parts, each part 17kg, is placed in 34L volume concentration respectively in the amyl alcohol of 80%, cold immersion 24h under normal temperature, this 3 parts after cold immersion Put the leaf pulp into the three extraction tanks respectively, add 136L amyl alcohol with a volume concentration of 80% to the first extraction tank, heat to 65°C-70°C, keep the temperature, and extract the first extraction tank after 20min Put the extract from the second extraction tank into the second extraction tank, heat to 65°C-70°C, and keep the temperature. After 20 minutes, extract the extract from the second extraction tank into the third extraction tank, heat to 65°C-70°C, and keep The temperature is 20 minutes, the obtained extract is filtered through a three-legged centrifugal bag (200 mesh), and the filtrate is taken; then 136L of amyl alcoho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com