Transmission system based on magnetic powder double-clutch design

A dual clutch and transmission technology, applied in clutches, mechanical equipment, components with teeth, etc., can solve the problems of small number of gears and small variation range, and achieve the effect of improving safety and good experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

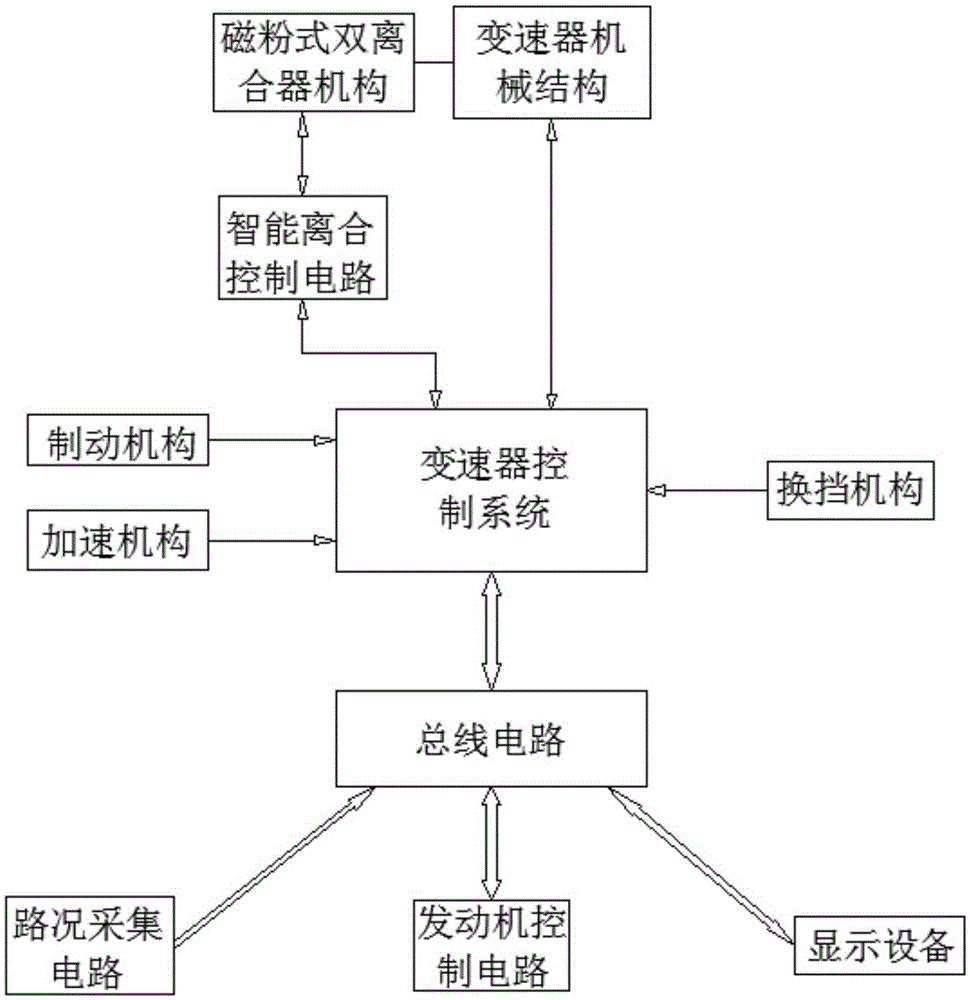

[0046] A transmission system based on magnetic powder dual clutch design, which adopts an intelligent control mode to control the automatic magnetic powder dual clutch mechanism, so that the driver has a better sense of experience, and can automatically perform the clutch according to different road condition information Position setting does not require the driver to switch the clutch position by himself, thereby improving driving safety, comfort and fuel economy; using the excitation current on-off control of the magnetic powder dual clutch to realize the switch between the working and non-working states of the magnetic powder dual clutch ; Use the linear increase and linear decrease of the excitation current of the magnetic powder dual clutch to complete the switching process of the magnetic powder dual clutch transmission torque, such as figure 1 As shown, the following structure is specially set up: including a transmission control system, a road condition acquisition circ...

Embodiment 2

[0051] This embodiment is further optimized on the basis of the above-mentioned embodiments, further in order to better realize the present invention, can meet the needs of different drivers, and can manually perform gear selection operations, such as figure 1 As shown, the following structure is particularly provided: a shifting mechanism is also included, and the shifting mechanism is connected to the transmission control system.

Embodiment 3

[0053] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, the braking operation can be performed in time to avoid collisions, such as figure 1 As shown, the following structure is particularly provided: a brake mechanism is also included, and the brake mechanism is connected to the transmission control system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com