Braking power generating mechanism based on air compression

A technology of braking power generation and air compression, applied in the direction of brake disc, brake type, electric braking system, etc., it can solve the waste of thermal energy consumption, recover braking energy, and the braking torque of the motor cannot meet the braking force demand of the whole vehicle, etc. problem, to achieve the effect of increasing the energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

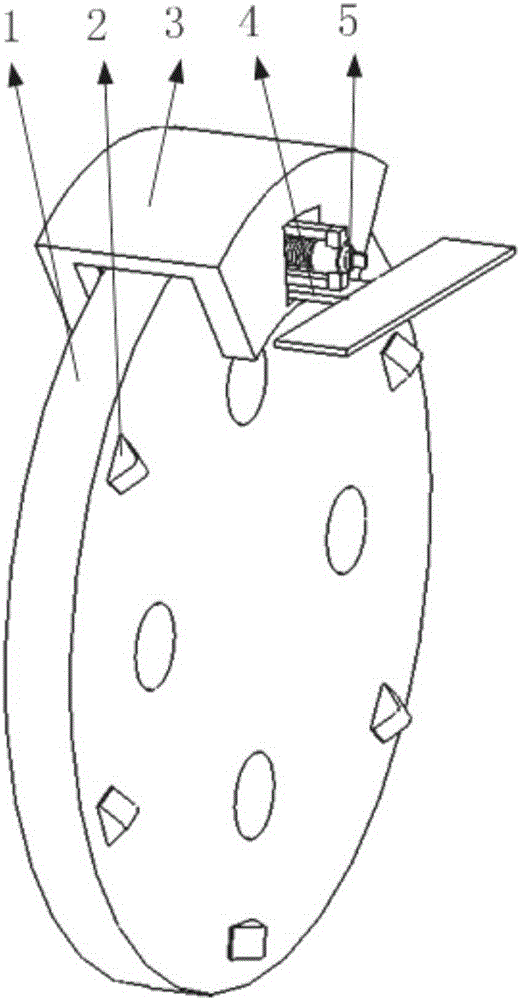

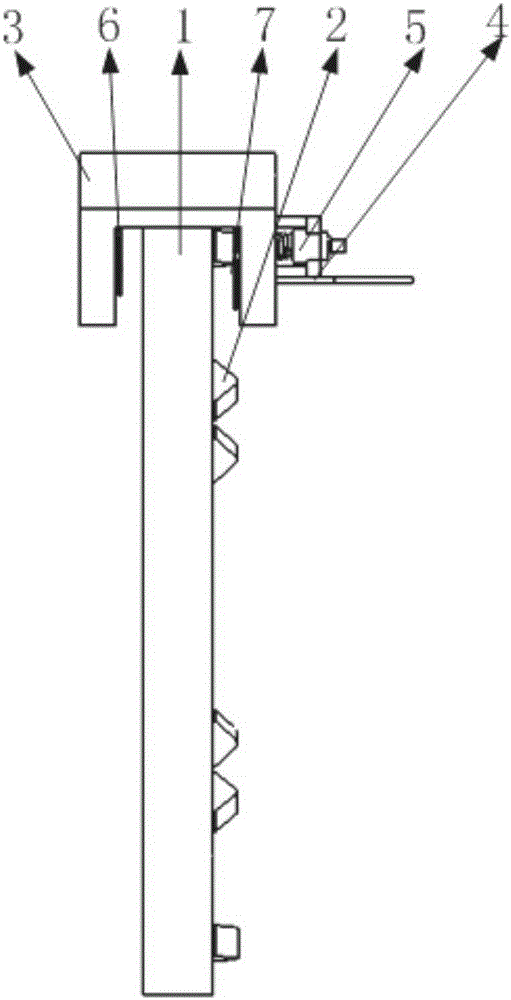

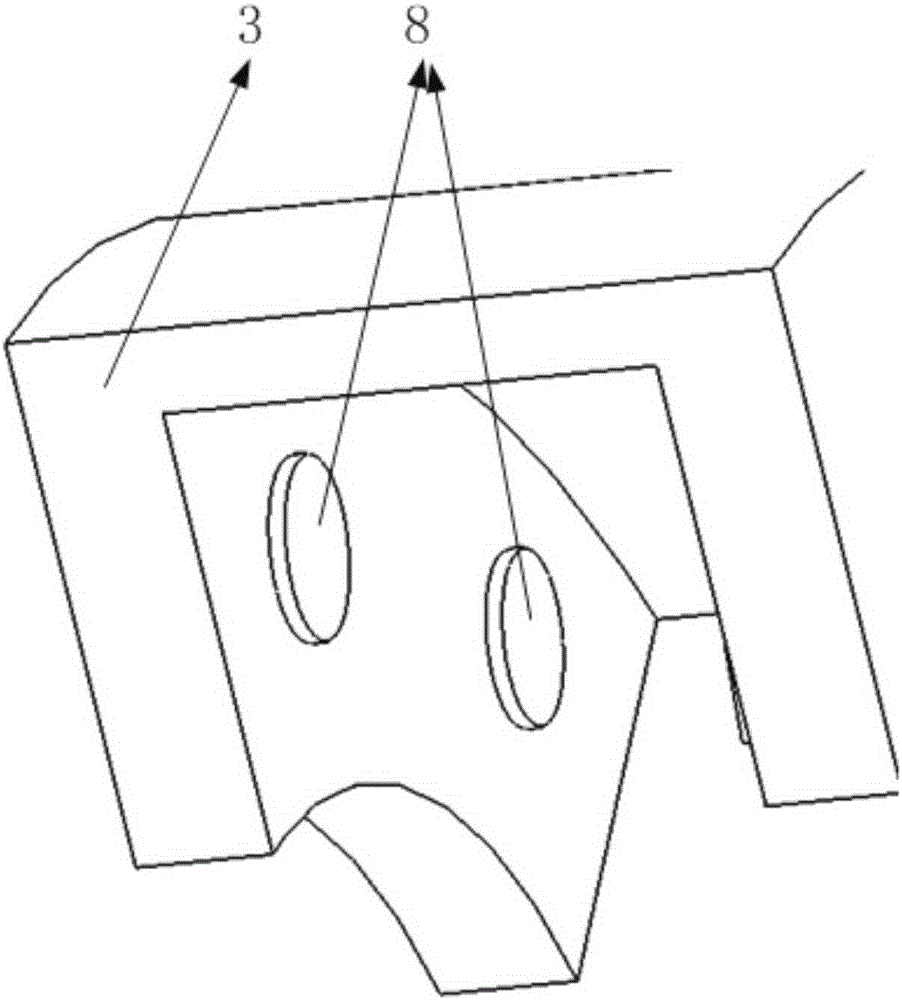

[0043] Such as figure 1 , 2 , 9, 17, 18, 19, 20, it includes brake disc, brake disc protrusion, brake mechanism support, first support plate, braking energy mechanical conversion mechanism, first brake pad bracket, second brake pad Bracket, first brake hydraulic column, second brake hydraulic column, bracket transition piece, second support plate, generator, generator support, air motor, third support plate, first compression cylinder, tie rod fourth support, second Compression cylinder, third compression cylinder, gas tank, gas tank support, tie rod third support, air motor shaft, tie rod second support, compression piston, tie rod first support, tie rod, gas tank air inlet, air tank outlet, Third compression cylinder air outlet, third compression cylinder air inlet, second compression cylinder air outlet, second compression cylinder air inlet, first compression cylinder air outlet, first compression cylinder air inlet, air motor air inlet , Air motor vent, air motor support, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com