Intelligent integrated testing device and method of low-temperature insulated gas cylinder valve

An integrated test and low temperature insulation technology, applied in the field of intelligent integrated test device for low temperature insulation gas cylinder valves, can solve the problem of inability to provide accurate information for valve development or judgment of quality, inability to monitor valve changes in detail, and large human errors and other issues to achieve the effect of compact structure, convenient access, and reduced manpower and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

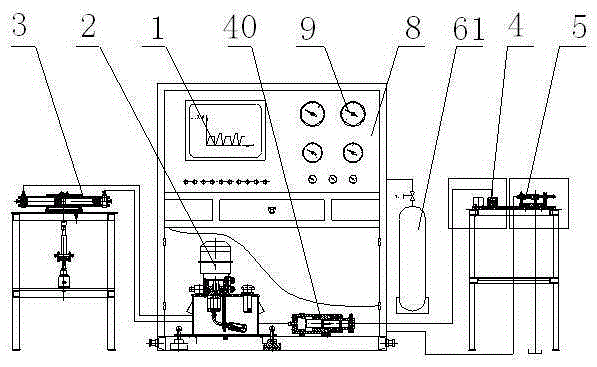

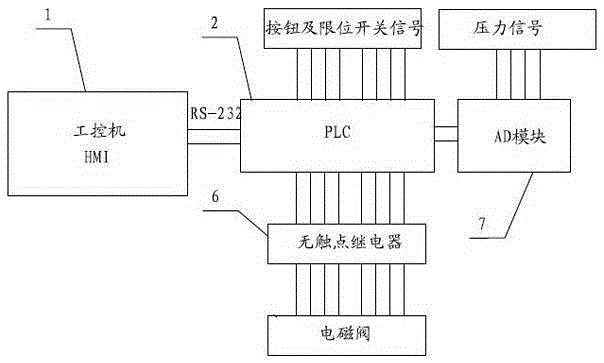

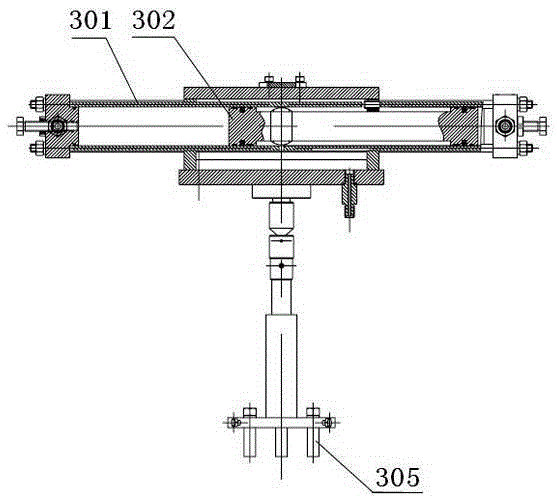

[0028] Such as figure 1 , figure 2 As shown, the intelligent integrated test device for the valve of the cryogenic insulating gas cylinder of the present invention includes an industrial computer 1, the industrial computer 1 is connected to the PLC control system 2 through the RS232 serial communication interface, and the input end of the PLC control system 2 is connected to the stop valve life test unit 3 , shell pressure test unit 4, the automatic / manual switching button and limit switch signal of the valve action performance test unit 5, the output end of the PLC control system 2 is connected to the stop valve life test unit 3, the shell via the non-contact relay 6 Body pressure test unit 4, solenoid valve coil of valve action performance test unit 5, the pressure sensor signal of the globe valve life test unit 3, shell pressure test unit 4, and valve action performance test unit 5 is passed through the A / D module 7 Connect PLC control system 2. The industrial computer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com