Power semiconductor module for integrating magnetic core of current sensor

A power semiconductor and integrated current technology, applied in the field of power semiconductor modules, can solve the problems of high cost, cumbersome dismantling of lines, slow response speed, etc., and achieve the effect of reducing subsequent use costs, realizing normal use, and increasing integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

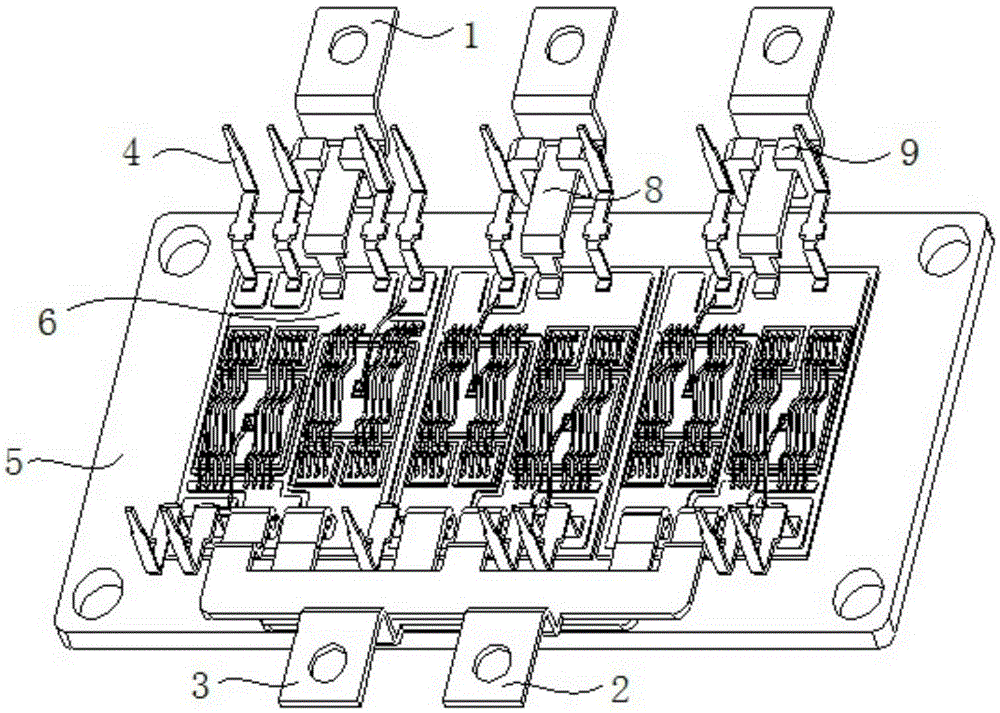

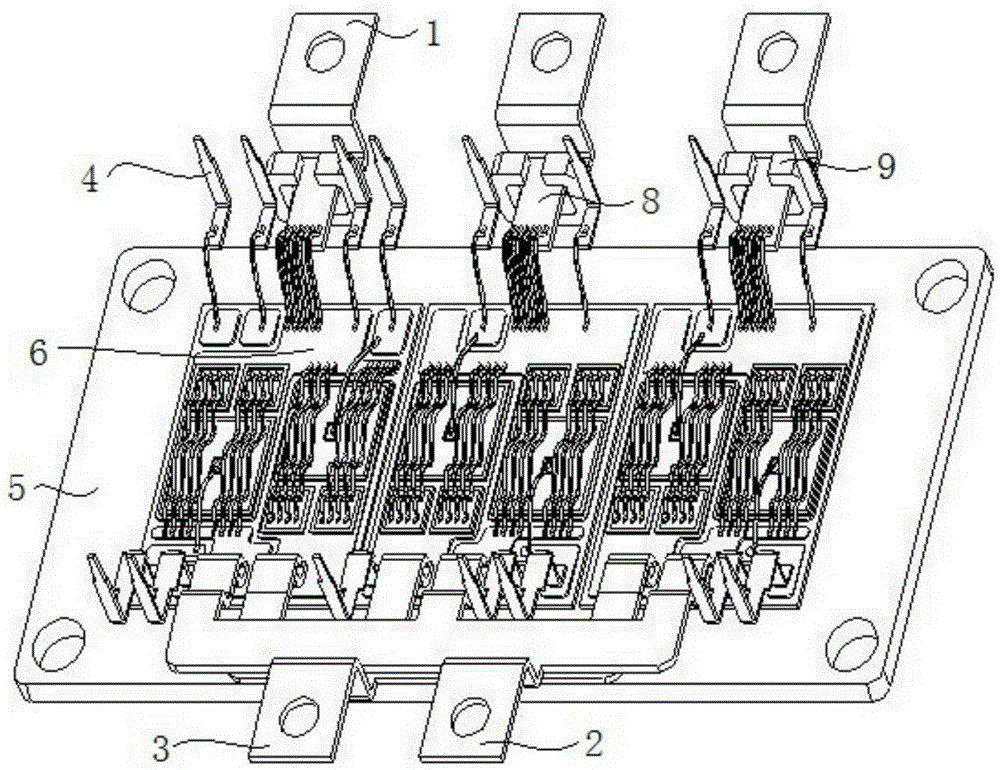

[0017] Such as figure 1 As shown, a power semiconductor module with an integrated current sensor magnetic core includes an output electrode 1, a negative electrode 2, a positive electrode 3, a sampling control terminal 4, a bottom plate 5, a ceramic substrate 6, and a housing 7. The output electrode 1 is connected to An output electrode arm 8 arranged parallel to the direction of the bottom plate 5, the output electrode arm 8 is connected to the ceramic substrate 6, a sensor core 9 is set on the output electrode arm 8, and the sensor core 9 is an open-loop Hall current sensor core. Each phase of the AC output electrode 1 passes through a sensor core 9 . The sensor core 9 has an upwardly facing core opening.

[0018] Such as Figure 5 As shown, when current sampling is required, a matching Hall element 11 is inserted into the opening of the magnetic core, and the pin of the Hall element 11 faces upward.

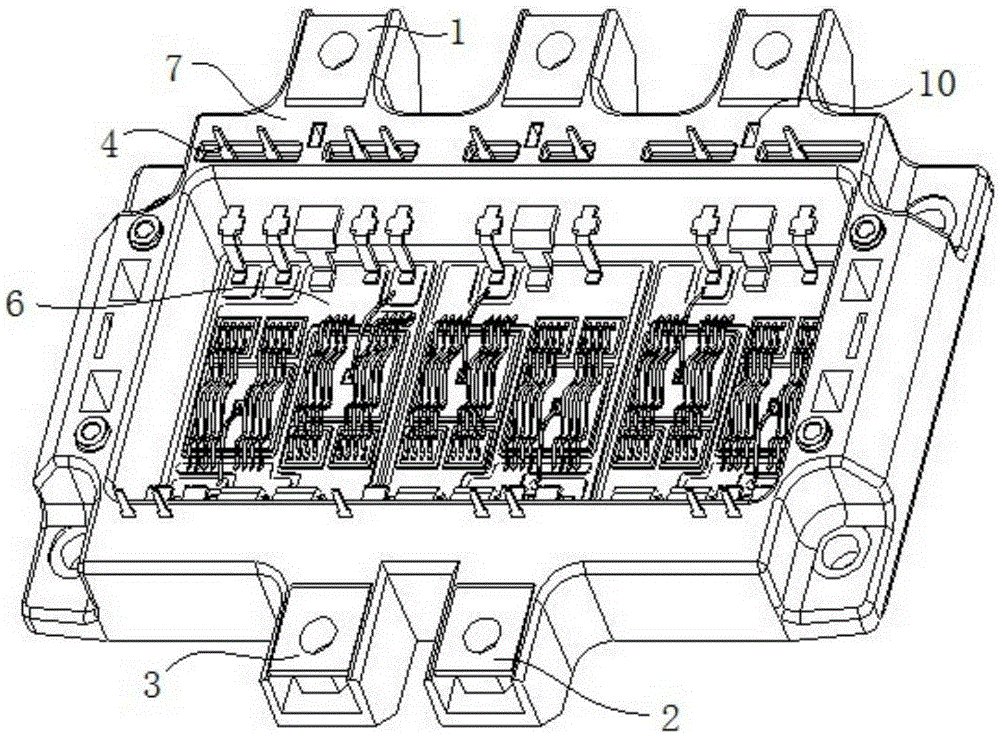

[0019] Such as image 3 As shown, in order to cooperate with the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com