Modular breaker

A circuit breaker, modular technology, applied in the direction of circuit, protection switch parts, electrical components, etc., can solve the problems of installation and maintenance inconvenience, achieve the effect of convenient maintenance, improve work efficiency, and avoid damage caused by killing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

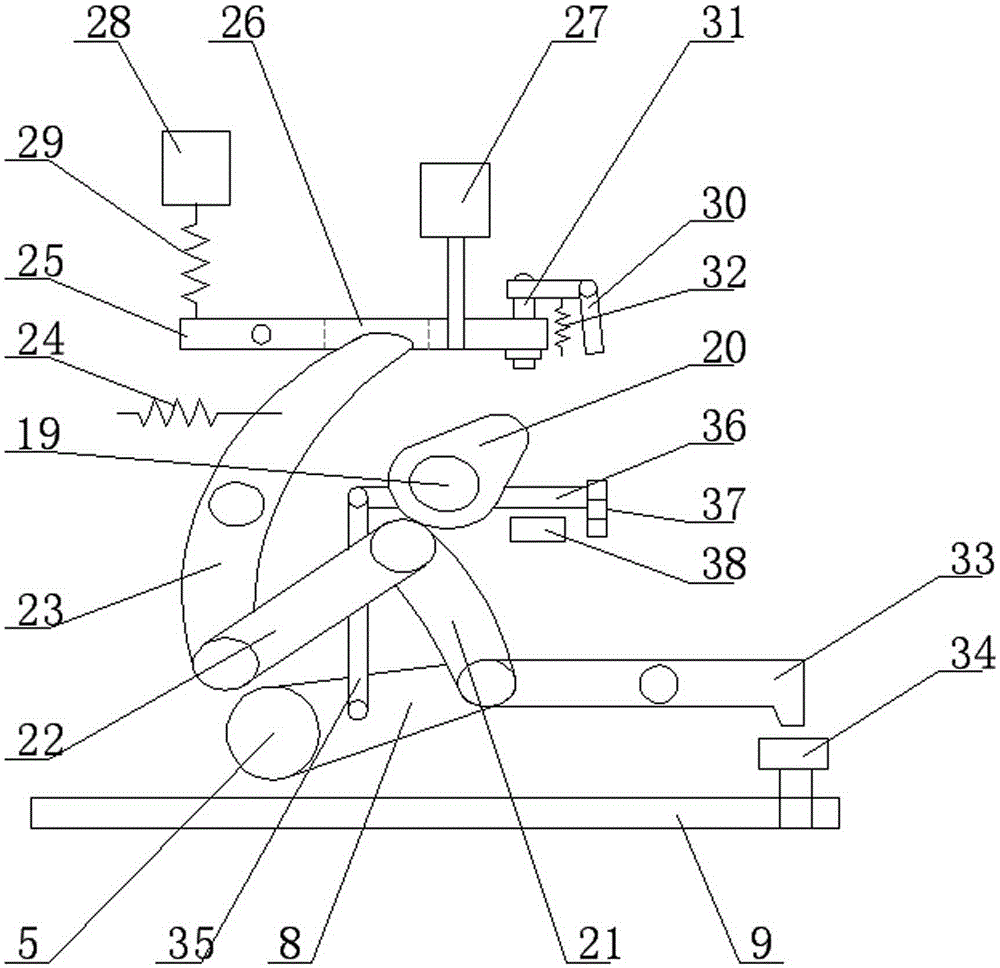

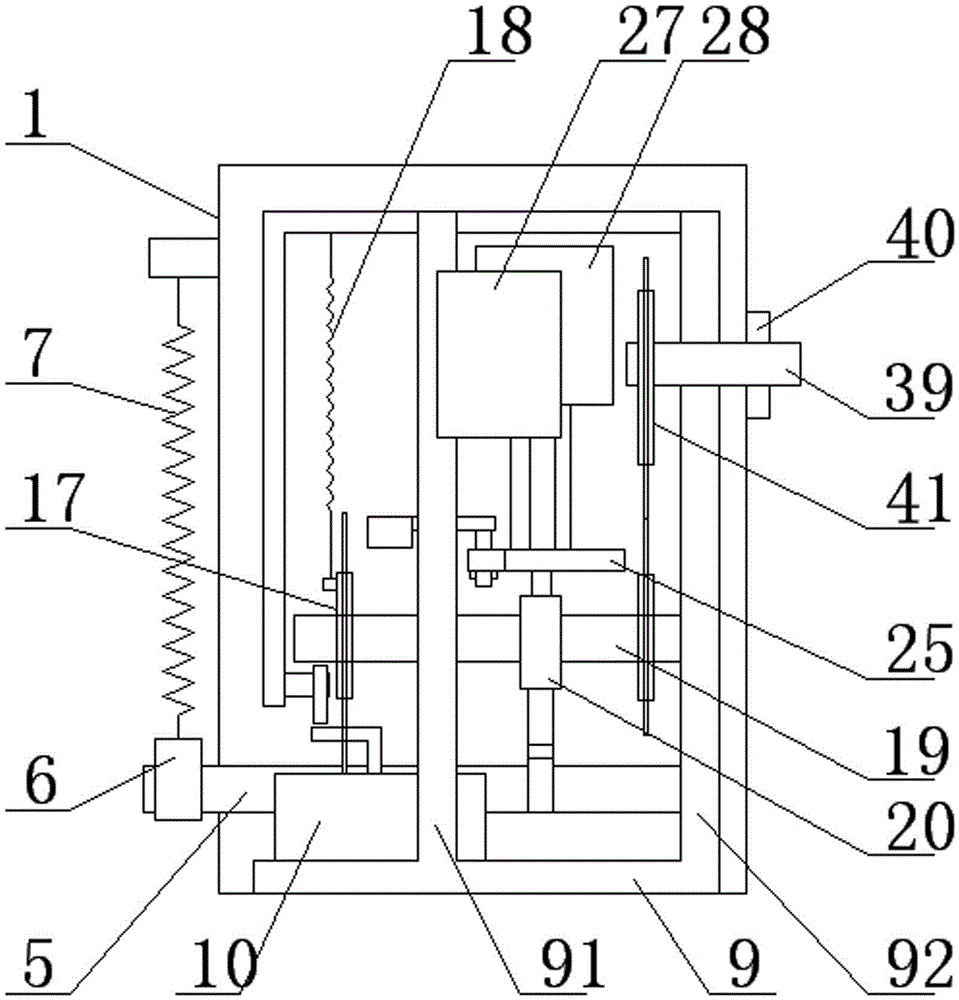

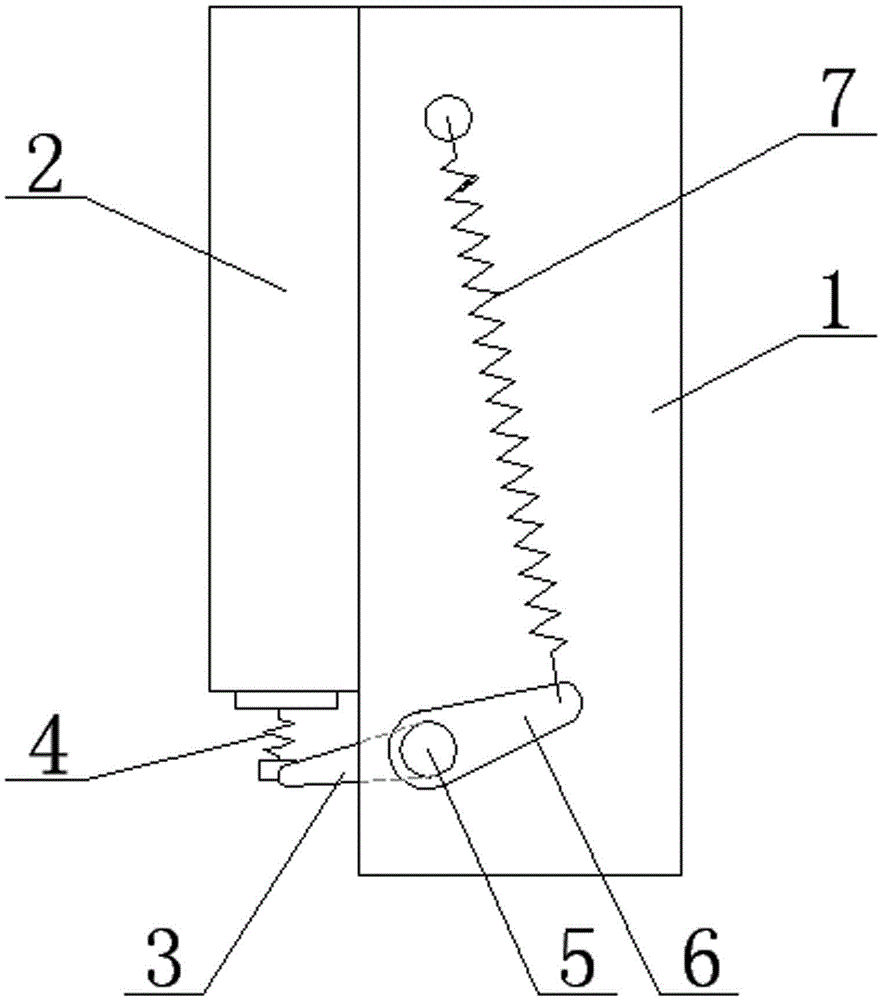

[0030] Figure 1-4As shown, a modular circuit breaker includes an insulating cabinet 1, a vacuum tube 2, an on-off toggle arm 3, an overtravel spring 4, a main shaft 5, an opening toggle arm 6, an opening tension spring 7, a closing toggle arm 8, and a mechanism Bottom plate 9, mechanism left and right vertical plates 91, 92, motor 10, input shaft 11, driving half clutch 12, clutch spring 13, driven half clutch 14, clutch lever 15, auxiliary switch 16, sprocket group 17, closing Tension spring 18, closing shaft 19, cam 20, closing plate 21, driving plate 22, sector plate 23, return spring 24, tripping plate 25, roller groove 26, electric tripping device 27, undervoltage tripping Device 28, undervoltage spring 29, gate opening plate 30, gate opening lever 31, gate opening reset spring 32, check lever 33, check adjustment screw 34, display pull rod 35, display lever 36, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com