Blocky sandwich cake forming machine

A molding machine and sandwich technology, which is applied to dough molding machinery or equipment, dough slitting machinery, baking, etc., can solve the problems of low production efficiency and low degree of automation, achieve reasonable structure, improve the degree of automation and production efficiency , to ensure the effect of forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

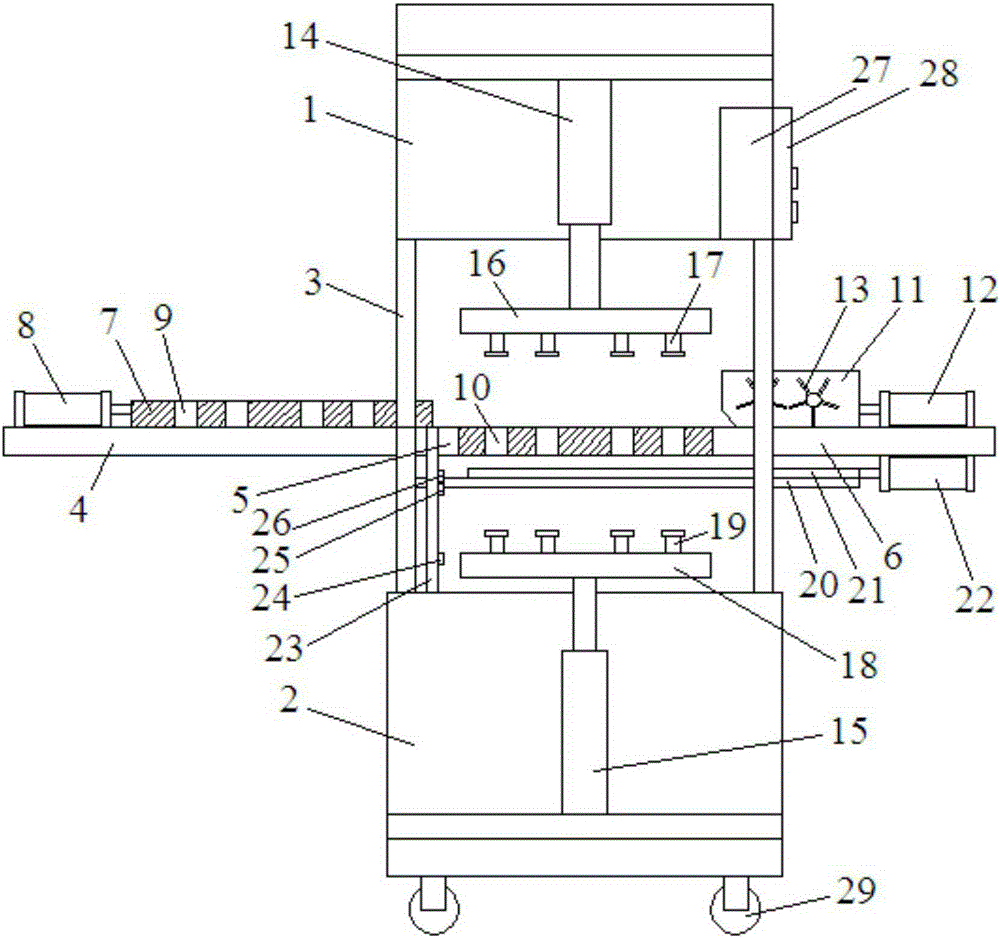

[0015] see figure 1 , a block sandwich pastry forming machine, including upper and lower boxes 1,2, the upper and lower boxes 1,2 are respectively connected by a plurality of connecting columns 3 around each other, the inner sides of the plurality of connecting columns 3 The front, middle and rear workbenches 4, 5 and 6 are respectively fixedly connected with each other. The front workbench 4 is respectively provided with a slide block 7 which can slide along its surface and a front cylinder 8 which drives the 7 slide block to move back and forth. 7 are respectively provided with a plurality of core grooves 9, and the middle workbench 5 is respectively provided with a plurality of forming grooves 10 corresponding to the plurality of core grooves 9, and the rear workbench 6 is respectively provided with a powder box which can slide along its surface 11 and the rear cylinder 12 that drives the powder box 11 to move back and forth. A plurality of stirring mechanisms 13 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com