Cake forming machine

A technology for forming machines and pastries, which is applied to dough forming machinery or equipment, dough slitting machinery, baking, etc., can solve the problems of low degree of automation and low production efficiency, and improve the degree of automation, production efficiency, structure, etc. Reasonable and ensure the effect of forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

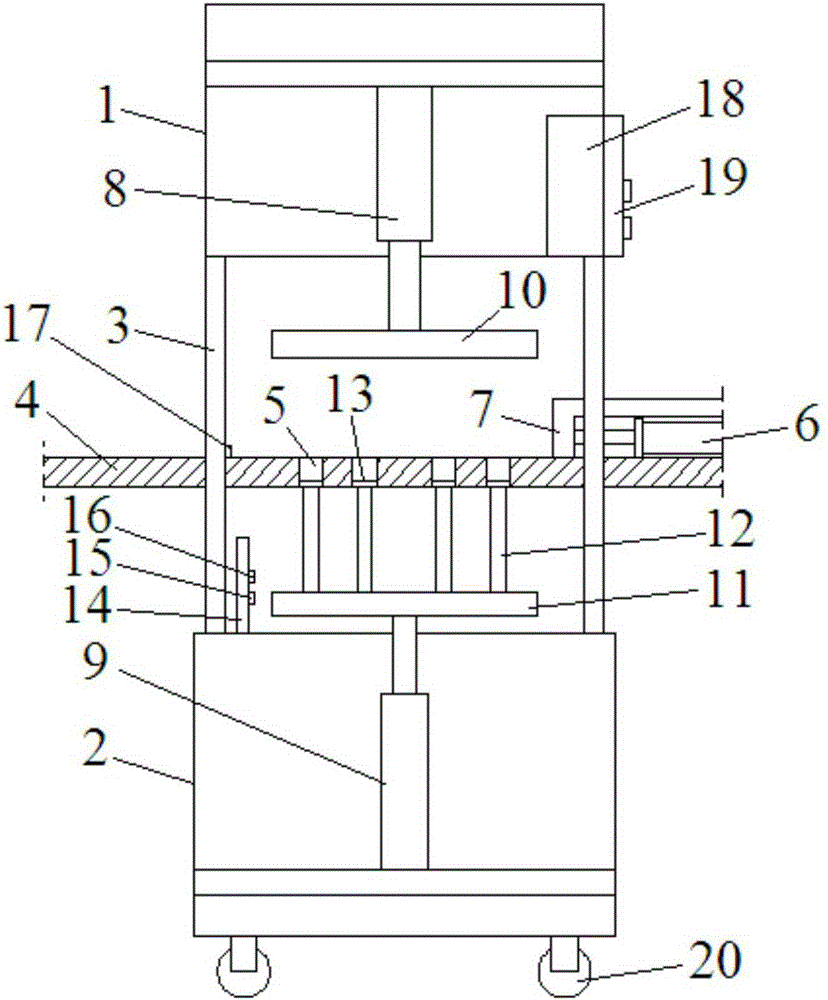

[0015] see figure 1 , a pastry forming machine, comprising upper and lower boxes 1, 2, the upper and lower boxes 1, 2 are respectively connected by a plurality of connecting columns 3 around each other, and the inner sides of the plurality of connecting columns 3 are fixed A workbench 4 is connected, and a plurality of forming grooves 5 are respectively arranged on the workbench 4. A cylinder 6 is installed behind the plurality of forming grooves 5 on the workbench 4. The piston rod of the cylinder 6 extends forward and is fixedly connected with a push plate. 7; Upper and lower hydraulic cylinders 8 and 9 are respectively installed in the upper and lower boxes 1 and 2, the piston rod of the upper hydraulic cylinder 8 extends downward to the top of the workbench 4 and is fixedly connected with a pressure plate 10, and the lower hydraulic cylinder 9 The piston rod extends upwards to the bottom of the workbench 4 and is fixedly connected with a bearing plate 11. A plurality of ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com