Energy-saving waste liquid recycling device

A waste liquid recovery and recovery tank technology, applied in separation methods, organic chemistry, evaporator accessories, etc., can solve the problems of long heating time, high cost, slow speed, etc., to save operating costs, cooling and evaporation speed, full cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

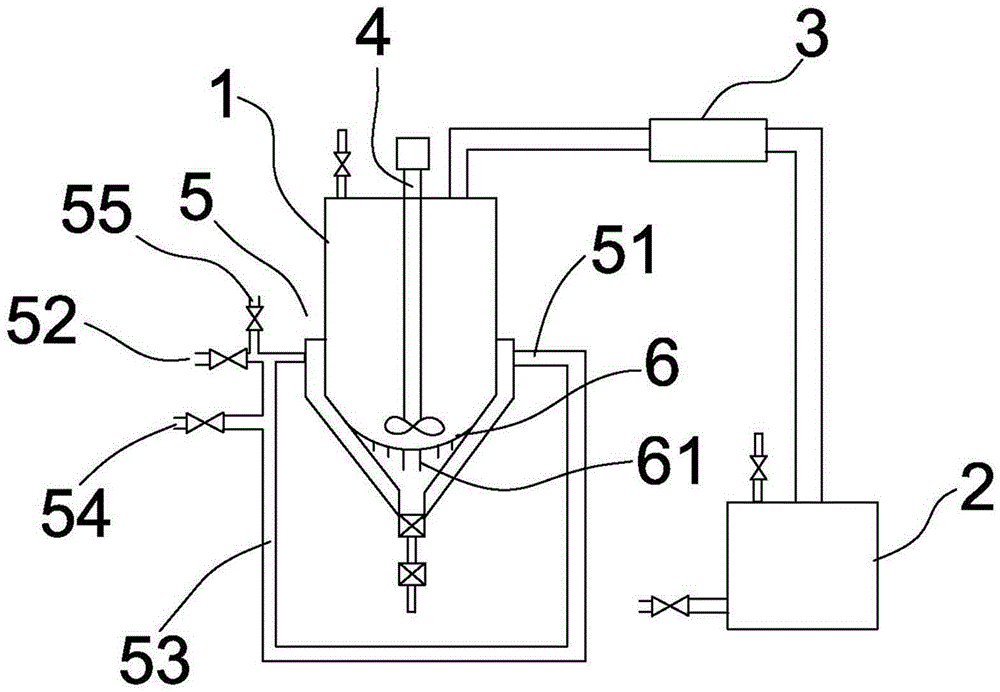

[0027] Embodiment 1: an energy-saving waste liquid recovery device, comprising a separation tank 1 and a recovery tank 2 connected to the separation tank 1, a cooling device 3 is provided between the separation tank 1 and the recovery tank 2, and the The separation tank 1 is provided with a stirring device 4 and a heating device 5, respectively. The heating device 5 is a jacket 51 arranged on the lower part of the outer surface of the separation tank 1. The jacket 51 is provided with a steam inlet 52. A steam circuit 53 is arranged on the jacket 51, and a steam outlet 54 is arranged on the steam circuit 53; a cooling gas inlet 55 is arranged at the steam inlet 52, and the steam inlet 52 and the cooling gas inlet 55 can only be selected from one another. One way to open.

Embodiment 2

[0028] Embodiment 2: an energy-saving waste liquid recovery device, comprising a separation tank 1 and a recovery tank 2 connected to the separation tank 1, a cooling device 3 is provided between the separation tank 1 and the recovery tank 2, and the The separation tank 1 is provided with a stirring device 4 and a heating device 5, respectively. The heating device 5 is a jacket 51 arranged on the lower part of the outer surface of the separation tank 1. The jacket 51 is provided with a steam inlet 52. A steam circuit 53 is arranged on the jacket 51, and a steam outlet 54 is arranged on the steam circuit 53; a cooling gas inlet 55 is arranged at the steam inlet 52, and the steam inlet 52 and the cooling gas inlet 55 can only be selected from one another. One way to open.

[0029] The stirring device 4 in the separation tank 1 is provided with a heat conduction part 6 connected to the inner wall of the separation tank 1. The heat conduction part 6 is a mesh curved downward on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap