Mechanical device for automatic pouring of cutting fluid

A mechanical device and automatic pouring technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of high brittleness, low production efficiency, and easy omission of alloy drill bits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

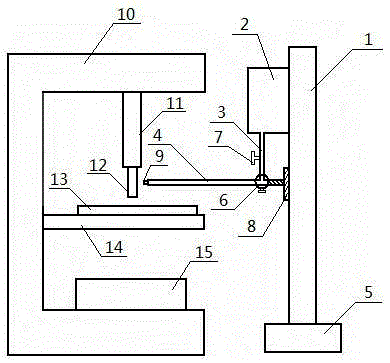

[0016] figure 1 It is a structural schematic diagram of a mechanical device for automatically pouring cutting fluid in an embodiment of the present invention; the mechanical device is made of stainless steel, and it consists of a bracket 1, a liquid storage tank 2, a telescopic branch pipe 3, a movable support arm 4, a drip nozzle 9 and a support seat 5, the liquid storage tank 2 is fixedly installed on the upper end of the bracket 1, the telescopic branch pipe 3 is located below the liquid storage tank 2 and connected to the liquid storage tank 2, the movable support arm 4 and the telescopic branch pipe 3 connected, one end of which is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com