Recovering and manufacturing process for polyurethane shoe materials and polyurethane-shoe-material injection-molding feeding mechanism for recovering and manufacturing process

A technology of feeding mechanism and manufacturing process, which is applied in the direction of coating, etc., can solve the problems of high recycling cost, hard shoe material quality, waste of resources, etc., and achieve the effect of low recycling cost, increased softness and bright surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A kind of recycling manufacturing process of polyurethane shoe material of the present invention is realized through the following steps:

[0027] 1. Crushing: Pour polyurethane shoe material waste into a powerful crusher for crushing to obtain granular waste with a particle size of 10-12mm. The optimal particle size of this particle waste is 10mm;

[0028] 2. Stirring: Pour the granular waste from step 1 into a heated low-speed mixer, and add rosin powder and additives for stirring. The stirring time is 80-100 minutes, and the stirring temperature is 100-110°C. The optimum temperature for this stirring is The temperature is 109°C, and the polyurethane injection plastic can be obtained; among them, the best stirring time is 100 minutes, and after stirring for 100 minutes, the stirring material has a rough feeling when grasped by hand, and it is dry and free of moisture;

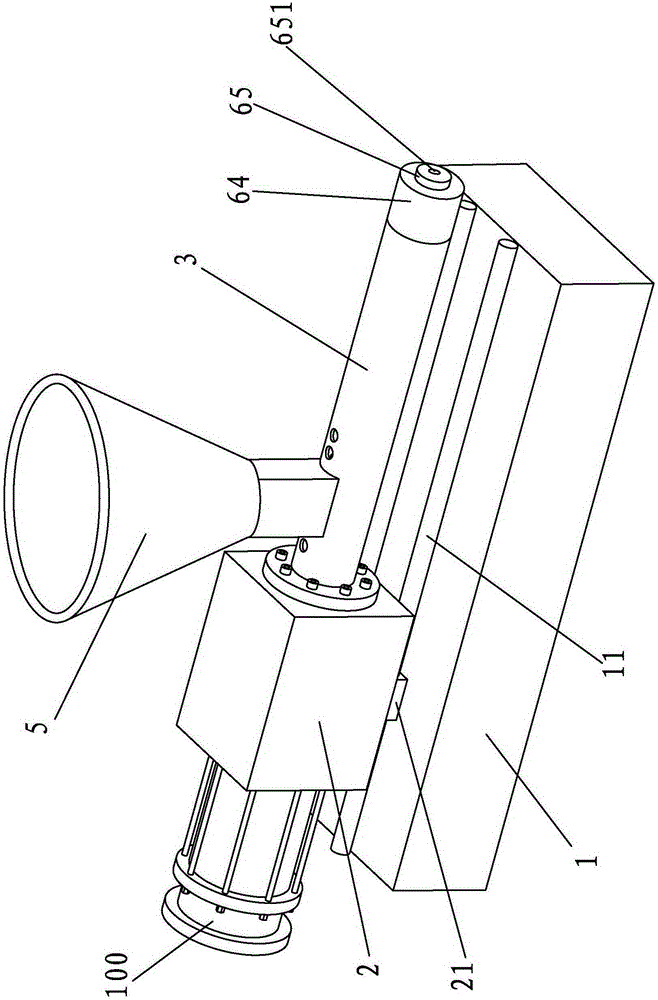

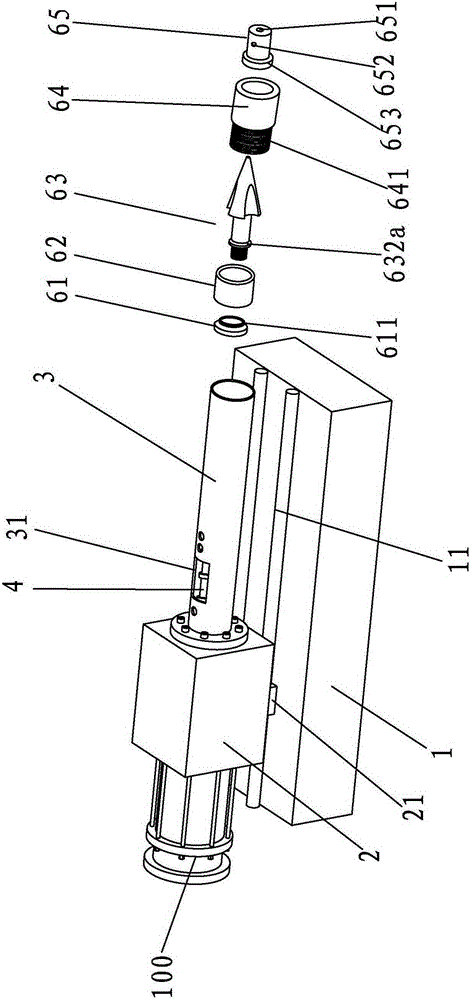

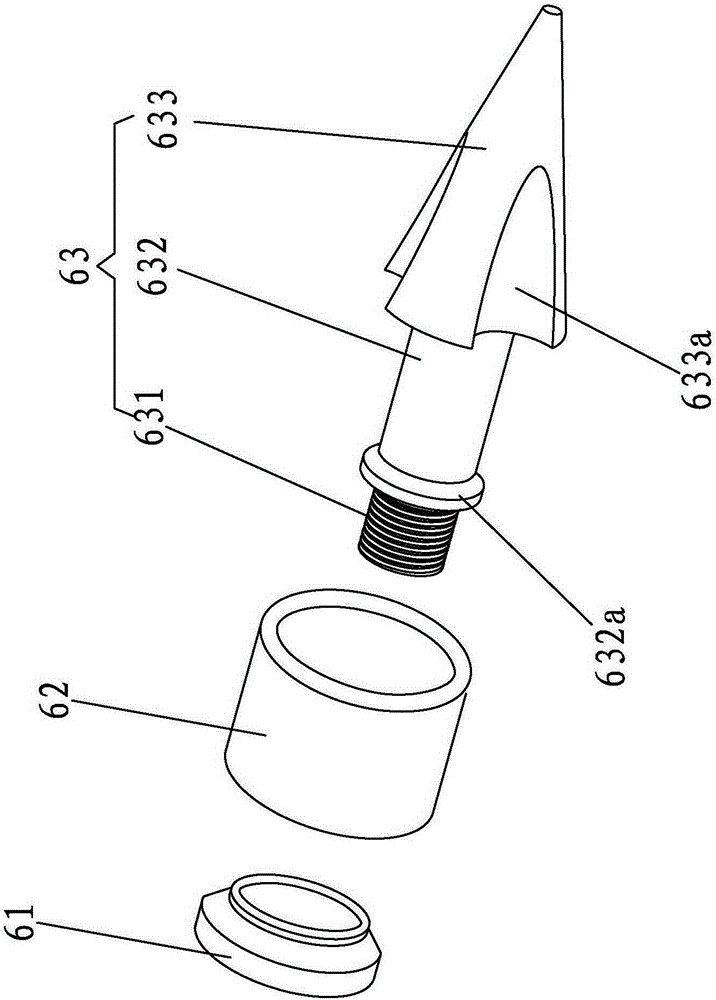

[0029] 3. Injection molding: Injection molding the polyurethane injection material in step 2 throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com