Preparation method of E0-grade melamine modified urea formaldehyde resin

A technology of melamine and urea-formaldehyde resin, which is applied in the field of urea-formaldehyde resin production, can solve the problems of high free formaldehyde, bonding strength, poor storage stability and water solubility, and achieve the effects of reducing formaldehyde release, increasing viscosity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

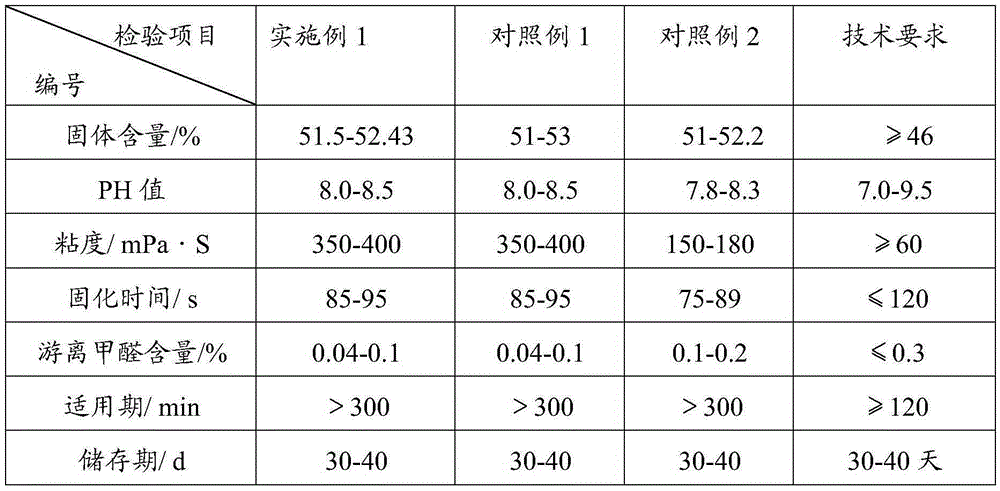

Image

Examples

Embodiment 1

[0036] 1. Raw material formula of urea-formaldehyde resin:

[0037] Raw material components

Parts by weight of each component (Kg)

formaldehyde

542.13

The first batch of urea

182.96

The second batch of urea

83.24

The third batch of urea

166.48

19.81

5.37

Appropriate amount

Appropriate amount

[0038] 2. The specific reaction steps are as follows:

[0039] To produce 1000 kg of E0 grade melamine-modified urea-formaldehyde resin, add 542.13Kg of formaldehyde solution and 5.37Kg of polyvinyl alcohol with a weight fraction of 37% to the reactor, heat the reactor with steam, and adjust the temperature of the reactor. When the temperature of the reaction solution reaches 60 °C, react for 10 minutes to obtain the first reaction solution.

[0040]Adjust the pH=8.0 of the first reaction solution described in the section wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com