High-fluidity high-low-temperature-resistance PC/TPEE alloy material and preparation method thereof

A technology of low temperature resistance and high flow, applied in the field of PC/TPEE alloy, can solve the problems of poor low temperature resistance, poor processing fluidity, low impact, etc., achieve high mechanical strength and aging resistance, excellent low temperature resistance, easy to form processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

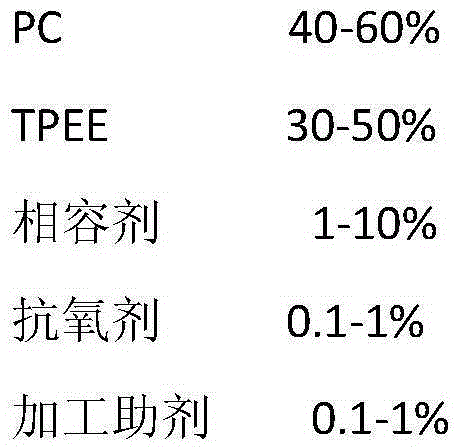

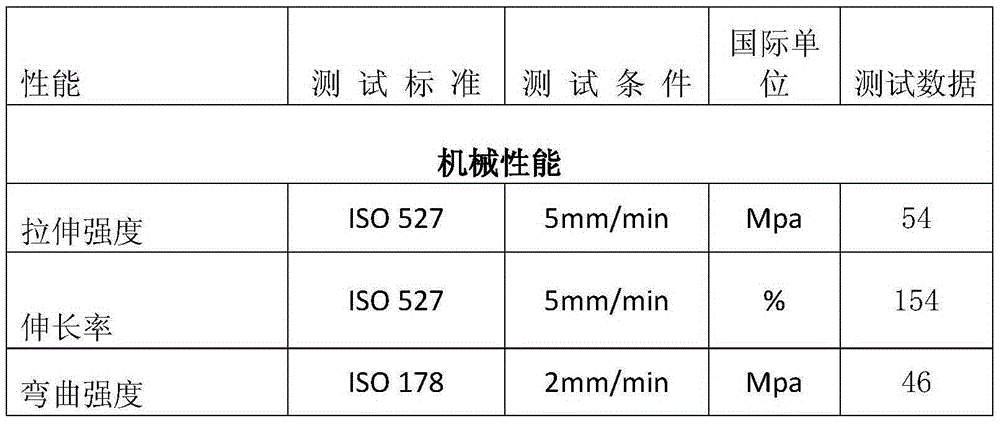

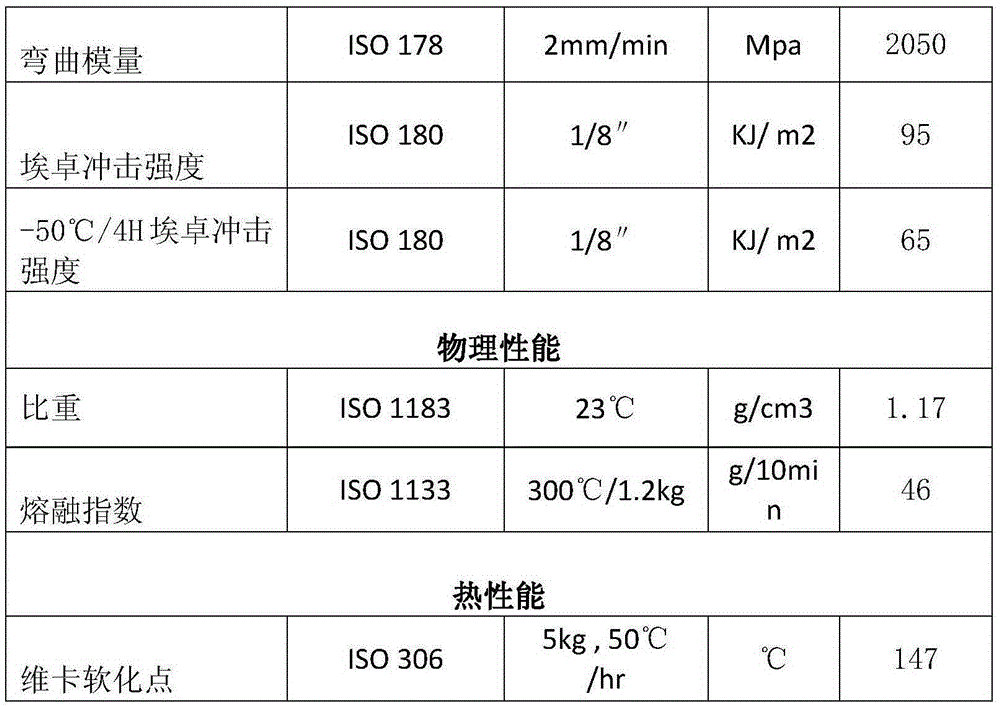

[0025] A PC / TPEE alloy material with high fluidity and low temperature resistance, comprising the following raw materials by weight

[0026] PC (Chi Mei) 40

[0027] TPEE (Changchun, Taiwan) 50

[0028] Compatibilizer 9

[0029] Antioxidant 0.3

[0030] Processing aid (high temperature resistant lubricant PETS) 0.7

[0031] The compatibilizer is ABS-g-MAH;

[0032] The antioxidants were selected from antioxidant 1076 (β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate) and antioxidant 168 (tri[2.4-di-tert-butyl Phenyl] phosphite) mixture, the mass ratio is 1:1.

[0033] The preparation method for preparing the above-mentioned PC / TPEE alloy material with high flow and high low temperature resistance is: according to the above-mentioned ingredients and proportioning and mixing uniformly, use a CTE35 twin-screw extruder for production, which contains 9 standard temperature control zones. Extrusion production process parameters: the temperature of zone 1 is 200°C,...

Embodiment 2

[0040] A PC / TPEE alloy material with high fluidity and low temperature resistance, comprising the following raw materials by weight:

[0041] PC (Idemitsu) 60

[0042] TPEE (Changchun, Taiwan) 33

[0043] Compatibilizer (ABS-g-MAH)6

[0044] Antioxidant (antioxidant 1076+antioxidant 168=2:1) 0.6

[0045] Processing aid (lubricant PETS) 0.4

[0046] The antioxidants were selected from antioxidant 1076 (β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate) and antioxidant 168 (tri[2.4-di-tert-butyl Phenyl] phosphite) mixture, the mass ratio is 2:1.

[0047] A preparation method of PC / TPEE alloy material with high fluidity and low temperature resistance is as follows: according to the above-mentioned ingredients and proportions, mix uniformly, and use CTE35 twin-screw extruder for production, which contains 9 stages of standard temperature control Area:

[0048] Extrusion production process parameters: the temperature of Zone 1 is 200°C, the temperature of Zone 2 ...

Embodiment 3

[0054] A PC / TPEE alloy material with high fluidity and low temperature resistance, comprising the following raw materials by weight:

[0055] PC (Idemitsu) 50

[0056] TPEE (Changchun, Taiwan) 44

[0057] Compatibilizer 5

[0058] Antioxidant (1076+168=1:1) 0.5

[0059] Processing aid (lubricant PETS) 0.5

[0060] The compatibilizer is styrene-acrylonitrile-glycidyl methacrylate copolymer

[0061] The antioxidant is selected from antioxidant 1076 (β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate)

[0062] The preparation method for preparing the above-mentioned PC / TPEE alloy material with high flow and high low temperature resistance is: according to the above-mentioned ingredients and proportioning and mixing uniformly, use a CTE35 twin-screw extruder for production, which contains 9 standard temperature control zones:

[0063] Extrusion production process parameters: the temperature of Zone 1 is 200°C, the temperature of Zone 2 is 235°C, the temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com