Manufacturing method for novel lightweight high-strength protective armor plate

An armor plate and high-strength technology, which is applied in the field of preparation of new lightweight and high-strength protective armor plates, can solve problems such as strict equipment weight requirements, and achieve the effect of increasing payload, improving long-distance delivery capability, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

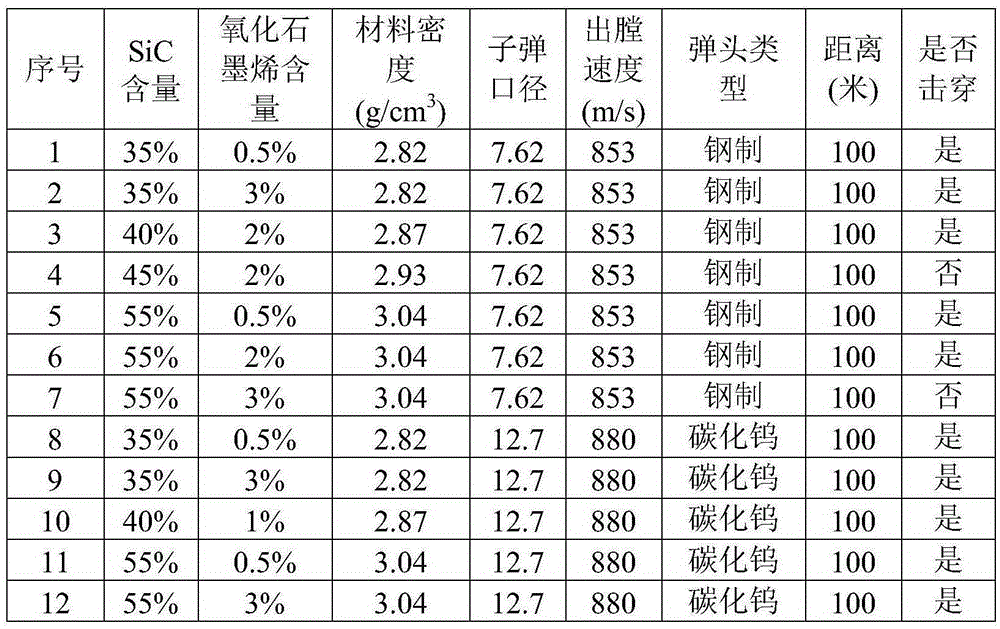

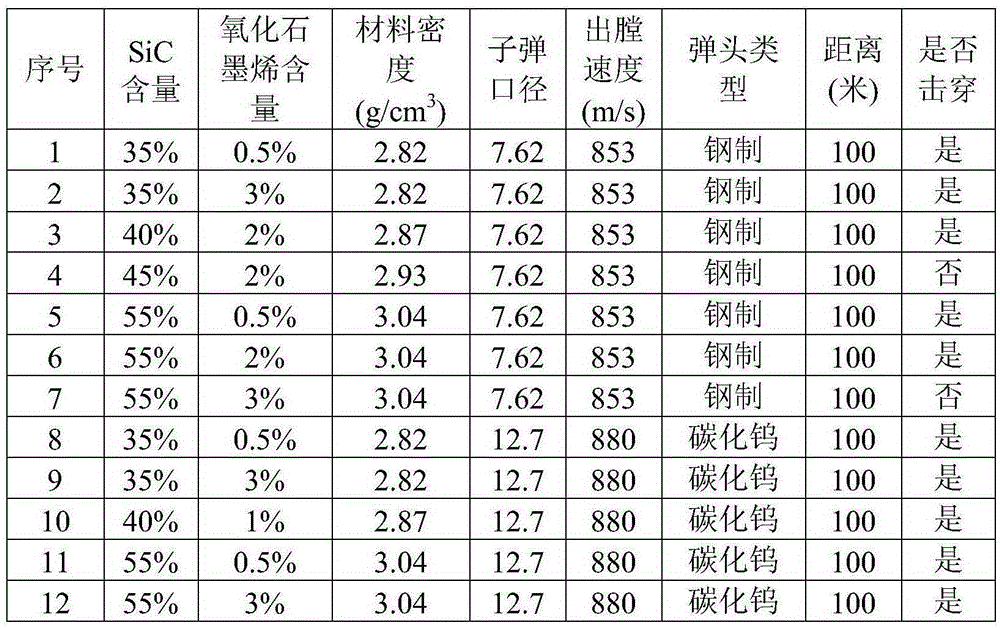

[0031] A new type of light-weight and high-strength protective armor plate preparation method, mixing graphene oxide, SiC and aluminum alloy powder, and then preparing a high-damping superhard bulletproof sandwich layer through thermophysical sintering, and using two or four layers of different thicknesses and materials The metal is thermally diffused and connected to the bulletproof sandwich layer, and finally forms a three-layer or five-layer sandwich biscuit composite structure with a density lower than 3.1g / cm 3 Lightweight and high-strength protective armor plate.

[0032] The preparation steps are as follows:

[0033] (1) V-type mixing equipment with a mass percentage of 0.5% to 3% graphene oxide, 35% to 55% SiC, and aluminum alloy powder with the remaining mass fraction at a speed of 10 to 30 rpm In the process, add ethanol solution at a volume ratio of 10:1, carry out wet mixing, and mix for 4 to 14 hours; then dry the mixed powder prepared by wet mixing, and put it i...

Embodiment 1

[0036] Example 1: 2mm thick LF21 aluminum alloy-24mm thick high damping superhard bulletproof sandwich layer-2mm thick LF21 aluminum alloy, two-layer structure, the ratio of the thickness of the high damping superhard bulletproof sandwich layer to the thickness of the unilateral sandwich metal plate is 3 : 1; thermal diffusion conditions: the pressure is 90MPa, and the time is 2 hours.

Embodiment 2

[0037] Embodiment 2: Using 2mm thick LF21 aluminum alloy-24mm thick high damping superhard bulletproof sandwich layer-2mm thick LF21 aluminum alloy, two-layer structure, the ratio of the thickness of the high damping superhard bulletproof sandwich layer to the thickness of the unilateral sandwich metal plate is 3 : 1; thermal diffusion conditions: the pressure is 300MPa, and the time is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com