Self-cleaning sanitary tool for DLC

A sanitary ware and self-cleaning technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as difficult formation of plasma, deposition, irregular shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

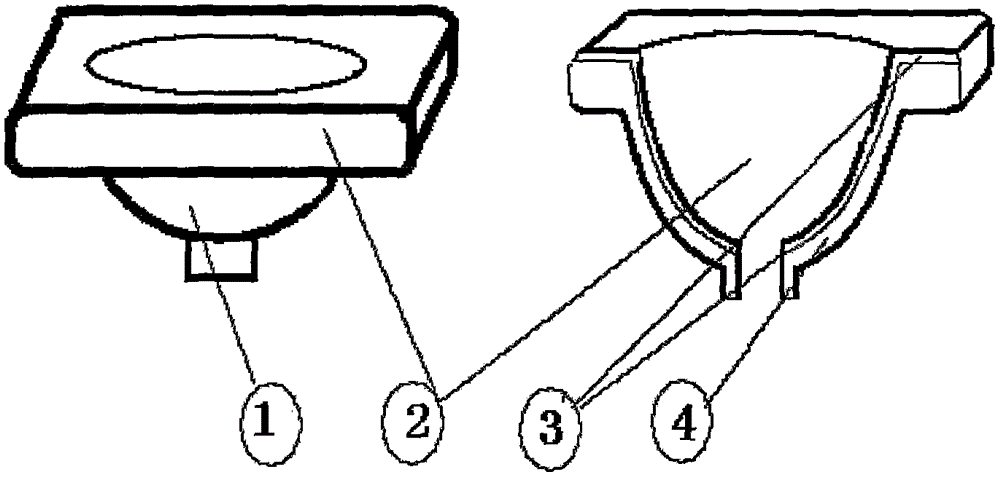

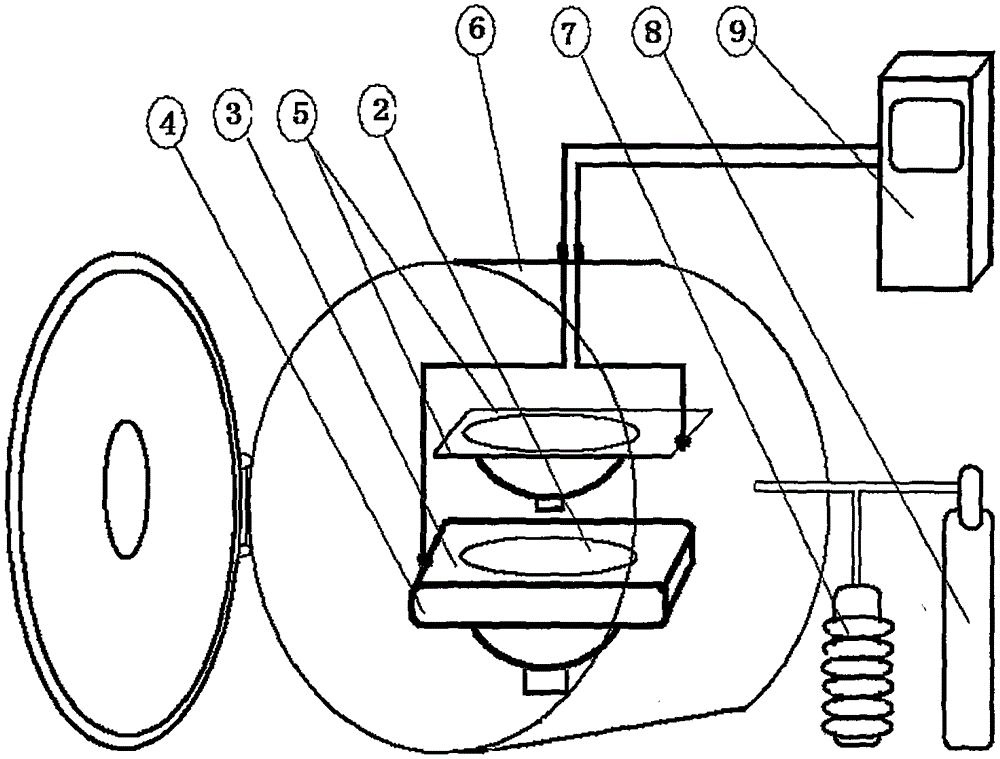

[0009] The optimal solution is to use magnetron sputtering technology to coat a metal aluminum film (3) with a thickness of about 0.5 microns on the surface of the sanitary ware (4), and then put the sanitary ware (4) into the vacuum plasma vapor phase chemical deposition diamond-like film ( 2) Just below the special-shaped electrode (5) in the vacuum chamber (6) of the equipment, connect the negative pole of the high-frequency bias power supply to the metal aluminum film (3) on the surface of the sanitary ware (4), and the special-shaped electrode (5) is connected to the sanitary ware (4) The conductive film (3) on the surface of the sanitary ware (4) together constitutes a plasma electric field. The vacuum plasma vapor phase chemical deposition diamond-like film (2) device is started, and the diamond-like film (2) is deposited on the surface of the conductive film (3) on the surface of the sanitary ware (4). You can get the DLC self-cleaning sanitary ware.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com