Track board with periodic structure characteristics and track board damping system

A technology of periodic structure and vibration reduction system, applied in the field of rail transit, can solve the problems of increasing the vertical dynamic displacement of the rail surface, the safety of train operation, the influence of comfort, and the influence of the safe operation of the upper vehicle, so as to achieve high comprehensive vibration reduction. Effects of performance, reduced safety and stability hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

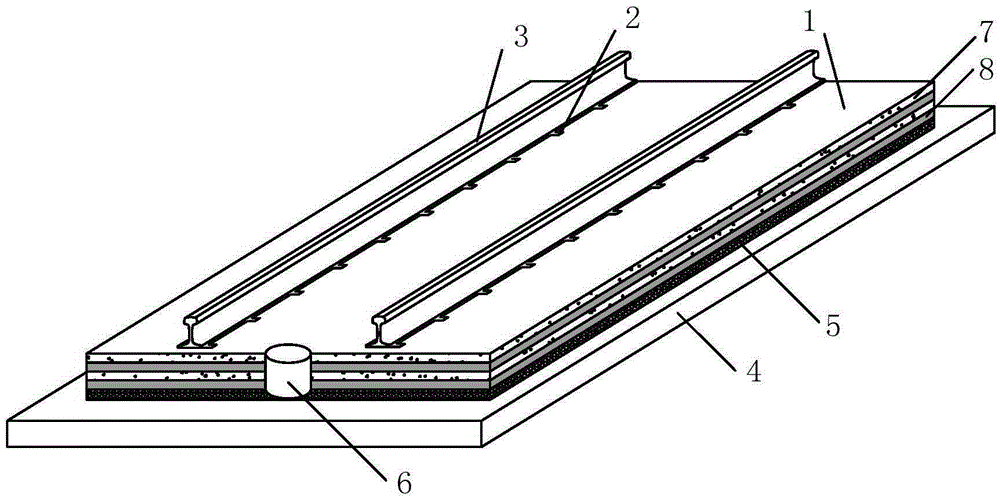

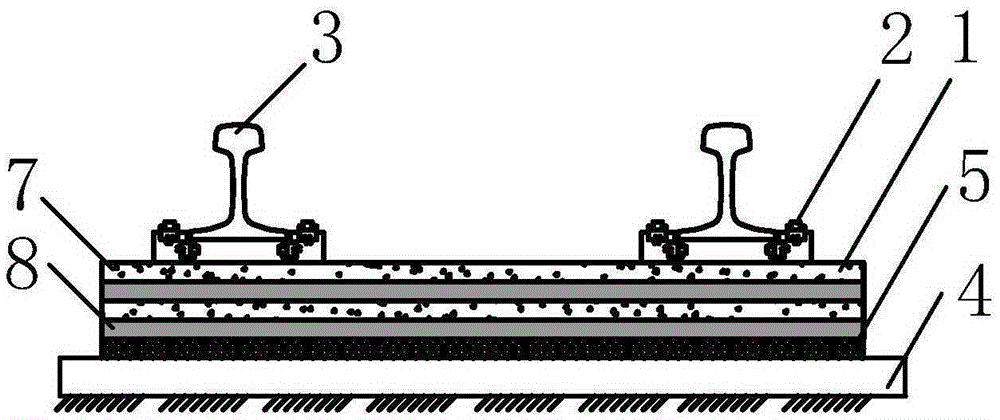

[0034] Embodiment 1: The track plate 1 is provided with several layered interval periodic substructures within the thickness range, the track plate 1 includes a first period substructure 7 and a second period substructure 8, and the first period substructure 7 and the second period substructure The structural dimensions of the substructure 8 are the same or similar, but the constituent materials are different. As preferred, the materials of the first period substructure 7 and the second period substructure 8 can be concrete, rubber and metal, etc., such as Figure 1-Figure 2 shown.

[0035] The thickness dimension design of the first period substructure 7 and the second period substructure 8 of the track plate 1 should consider the factors such as track height and vibration damping effect, as a preference, take the first period substructure 7 and the second period substructure 8 The thickness dimension is consistent with the vibration wavelength of interest, and the vibration ...

Embodiment 2

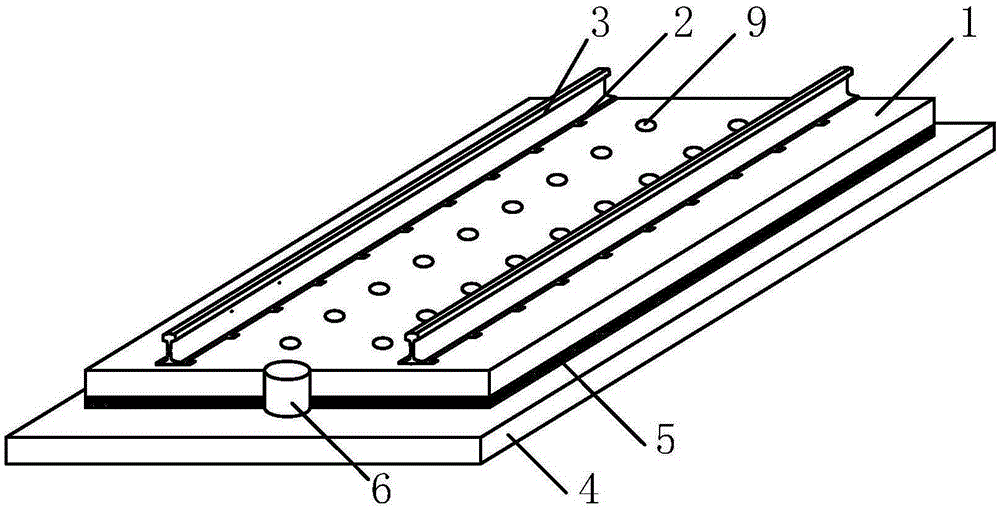

[0039] Embodiment 2: The periodic track plate 1 can also be provided with some periodic slave structures in the length direction, the width direction, or the length direction and the width direction at the same time, and these periodic slave structures include holes 9 and filling bodies 10, and the These holes must have the same structure size, the same regular distribution, and equal spacing in all directions. At the same time, it is also possible to consider setting some columns or cones and filling bodies 10 of other shapes in these holes 9, and then connect with the periodic track plate 1 Folded into a whole, presenting a certain periodical arrangement at equal intervals in the lengthwise direction and the widthwise direction, such as Figure 3-Figure 5 shown. Preferably, in addition to the form of the columnar periodic slave structure 9, a conical periodic slave structure can also be used, either a forward cone or an inverted cone, which has a good vibration damping effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com