Sloping roof structure

A sloping roof and sloping surface technology, applied in the field of machinery, can solve the problems of complex cold bridge and gutter joints, failure to consider climatic characteristics, etc., and achieve the effects of low material cost, good thermal insulation effect, and good fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

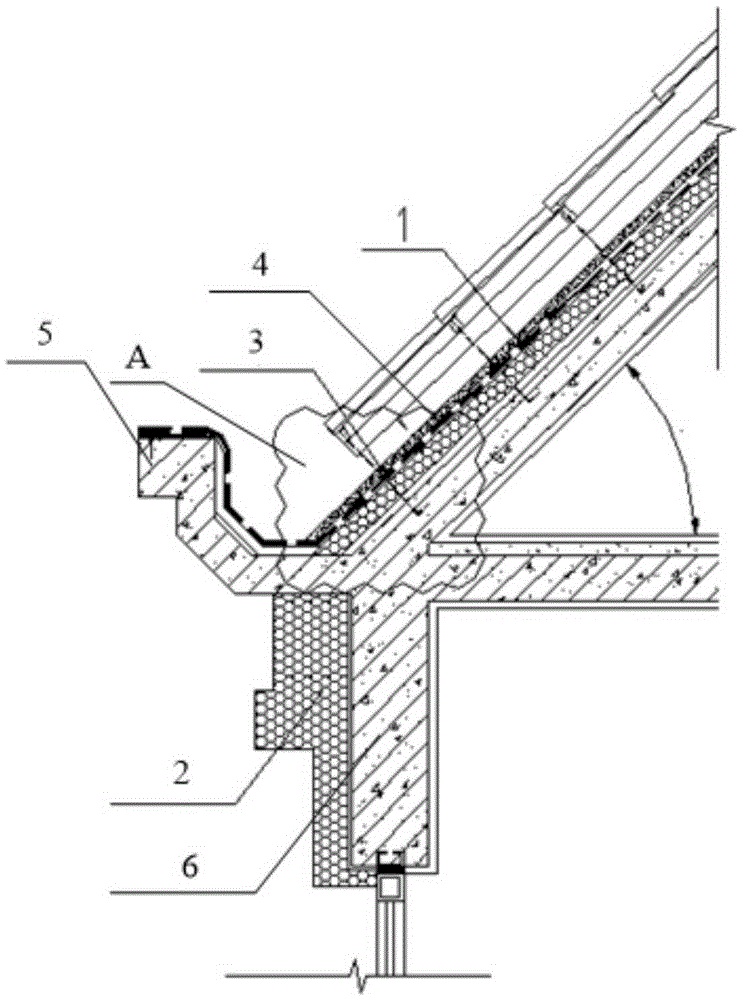

[0021] The application will be described in further detail below in conjunction with the accompanying drawings.

[0022] The present application provides a sloping roof structure, the sloping roof structure comprising: a sloping surface main body, the sloping surface main body has a first insulation layer 1, wherein the material of the first insulation layer 1 is graphite polystyrene insulation Plate (SEPS); gutter node 5, the gutter node 5 is set outside the lower edge of the slope main body, wherein the slope main body is flat and has no convexity near the connection with the gutter node 5 flat.

[0023] Further, the gutter node 5 includes a bottom groove and an outer groove, the bottom groove is in contact with the lower edge of the slope main body, and the gutter node 5 is integrally connected with the slope main body.

[0024] The sloping roof structure of this application uses graphite polystyrene foamed plastic board (SEPS) as the first insulation layer 1, wherein the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com