High-performance cement mortar board built-in lightweight ecological material T-shaped thermal insulation and load-bearing blocks

A cement mortar and ecological material technology, applied in building materials and other directions, can solve the problems of poor fire resistance, durability, impact resistance, complicated construction procedures, and high comprehensive cost, and achieves prevention of cold bridges, saving of leveling and plastering, and good thermal insulation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

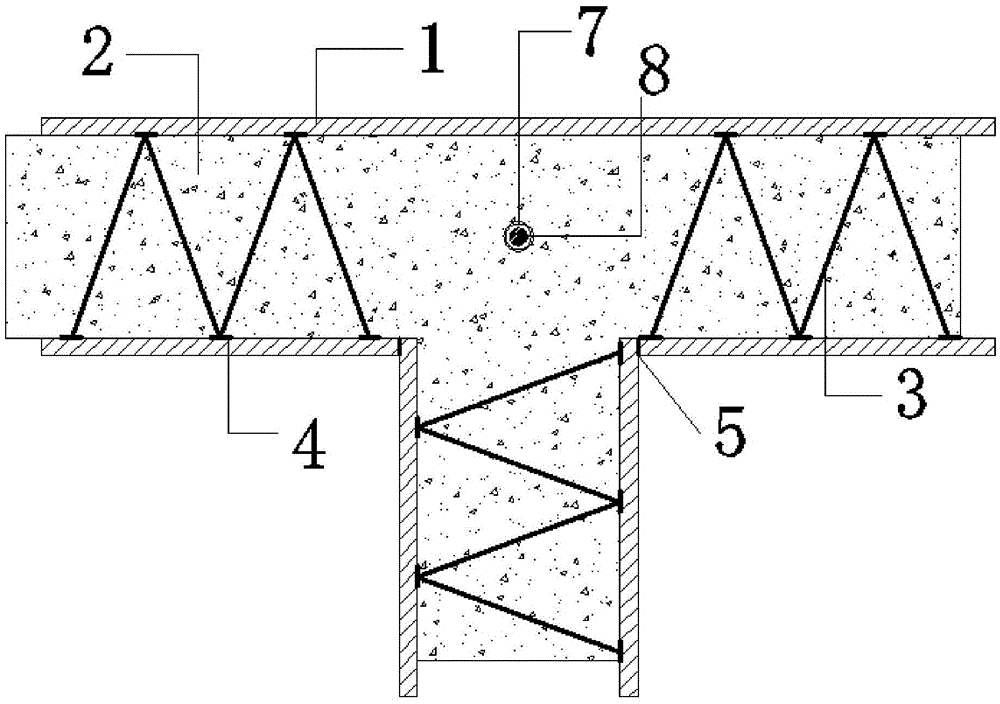

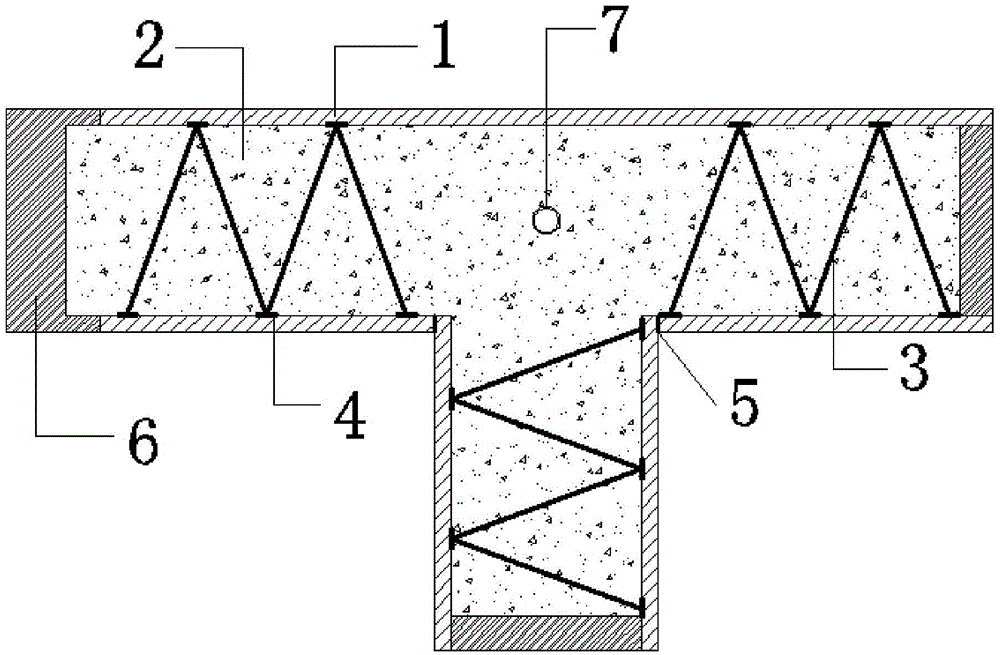

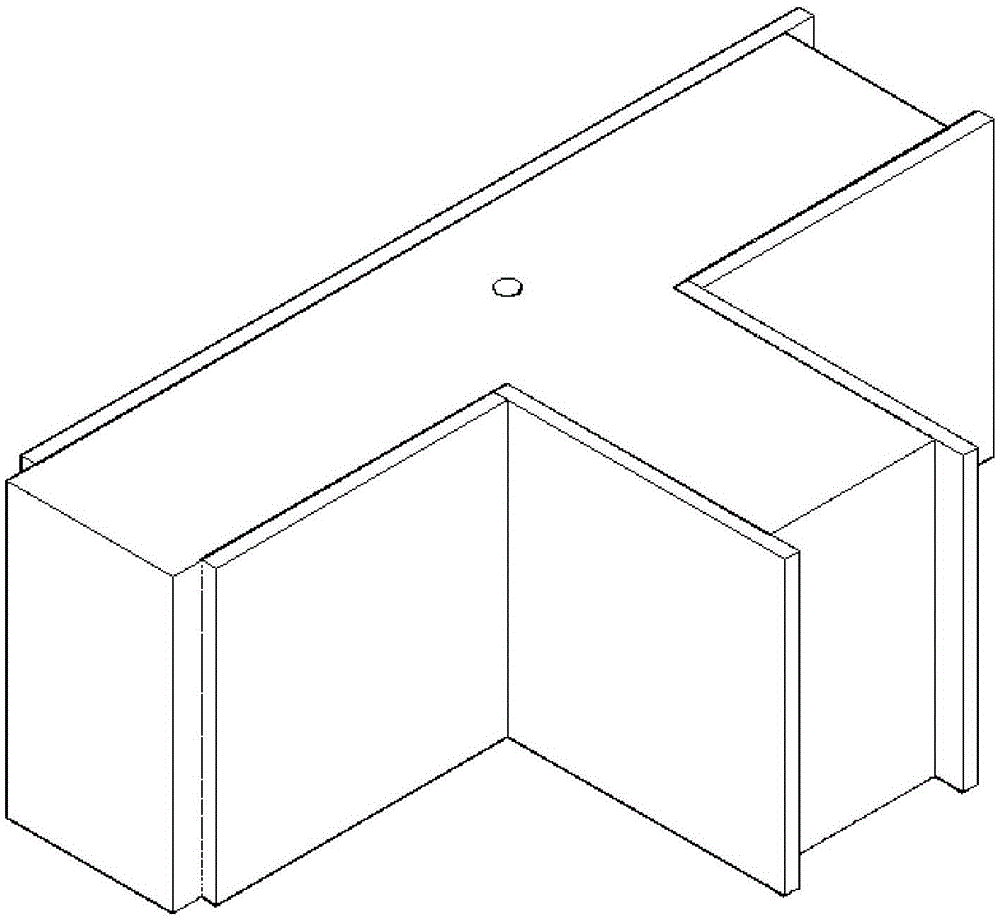

[0015] Schematic diagram of the structure of T-shaped thermal insulation and load-bearing blocks built in high-performance cement mortar boards with light ecological materials figure 1 , figure 2 , image 3 , Figure 4 shown. Steel wire mesh mortar boards 1 are pasted on the periphery of the block except for the ends; the inside of the block is filled with lightweight ecological materials 2; steel trusses or other connectors 3 are set between the mortar boards 1 on both sides of the block, A prefabricated embedded part 4 is arranged on the board 1, and the steel truss 3 is welded to the prefabricated embedded part 4, and the steel mesh mortar board 1 is bonded with a high-strength polymer mortar 5; a round hole 7 is reserved at the intersection of the T-shaped blocks, Pass a vertical tie bar 8 through, and the production sequence is as follows,

[0016] S1 selects HPB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com