Method for determining thermal-conduction resistance of metal foam porous medium

A technology of metal foam and porous media, which is applied in the field of measuring the thermal conductivity of metal foam porous media, can solve the problems of inaccurate thermal conductivity and complex thermal conduction process, and achieve the effect of high accuracy and fast measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

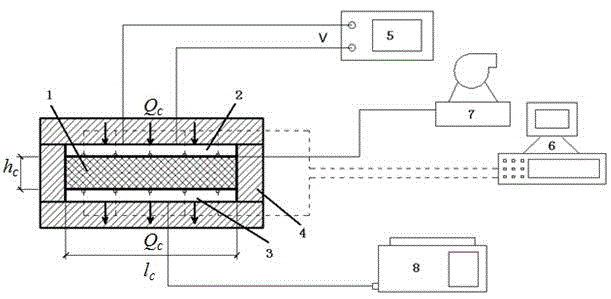

[0011] The experimental system includes metal foam porous medium 1 to be tested, heating plate 2, cooling plate 3, thermal insulation material 4, regulated power supply 5, data acquisition and processing system 6, vacuum system 7 and cooling module 8. The metal foam porous medium 1 is arranged with a heating plate 2 and a cooling plate 3 respectively. The upper and lower outer surfaces of the heating plate 2 and the cooling plate 3 in contact with the environment, and the other four surfaces of the test section are all made of high thermal insulation materials 4 Make a seal. The heating plate 2 is connected with a voltage-stabilized power supply 5, and is energized and heated by the voltage-stabilized power supply 5. The cooling plate 3 is connected to the cooling module 8 . The vacuum system 7 is connected with the metal foam porous medium 1 . A plurality of thermocouples are respectively arranged between the metal foam porous medium 1 and the heating plate 2 and the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com