Low-frequency electromagnetism-based defect detecting device

A defect detection, low-frequency technology, applied in the direction of material magnetic variables, etc., can solve the problems of lack of systematic research, not widely used, slow detection speed, etc., to achieve the effect of overcoming the skin effect, convenient operation, and improving the detection depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

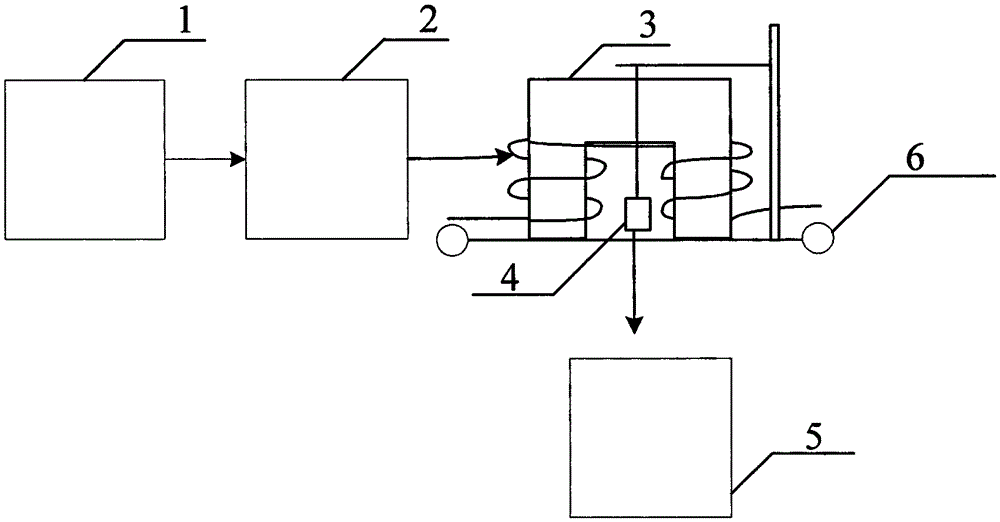

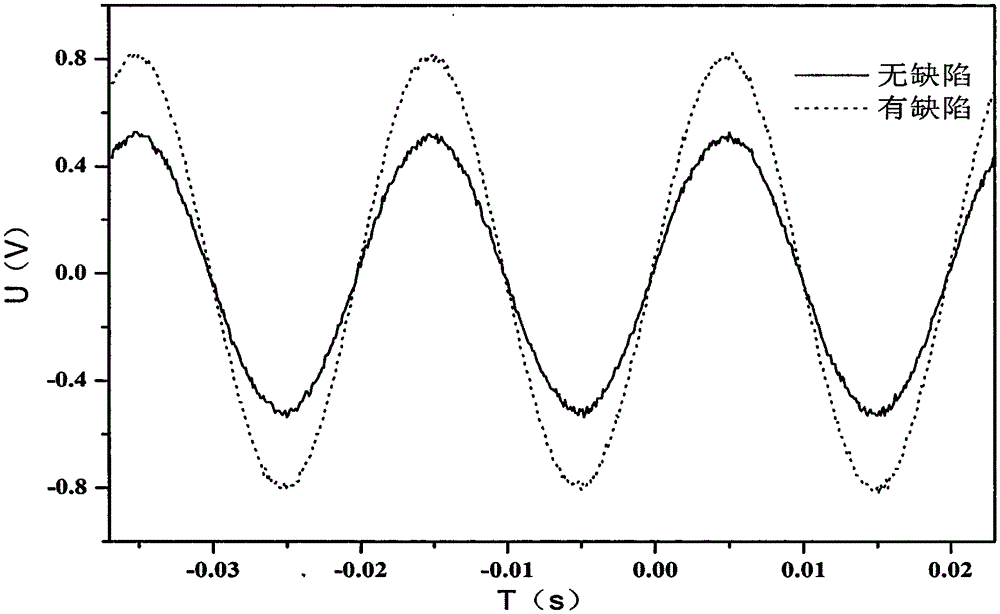

[0013] See attached figure 1 , a defect detection device based on low-frequency electromagnetics, consisting of a signal generator (1), a power amplifier (2), an excitation coil (3), a Hall element (4), an oscilloscope (5) and a bracket (6); the signal The generator (1) generates a low-frequency sinusoidal signal of 1-100 Hz. After being amplified by the power amplifier (2), the signal will generate a magnetic field after passing through the exciting coil (3) placed on the bracket (6), and the defect will cause the magnetic field to change. , the Hall element (4) can sense this magnetic field change and display it through the oscilloscope (5).

[0014] The frequency of the sinusoidal signal generated by the signal generator (1) is 1-100Hz. The excitation coil (3) uses U-shaped manganese zinc ferrite as the magnetic core, which is composed of two coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com