A sodium hydroxide standardization device directly connected to a translationally-moved pedestal in a sulfur determinator

A sodium hydroxide and calibration device technology, which is applied in the direction of chemical analysis by combustion, analysis by making materials undergo chemical reactions, and material analysis by observing the impact on chemical indicators, can solve problems such as high labor intensity, Achieve smooth movement, improve calibration accuracy, improve calibration efficiency and calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

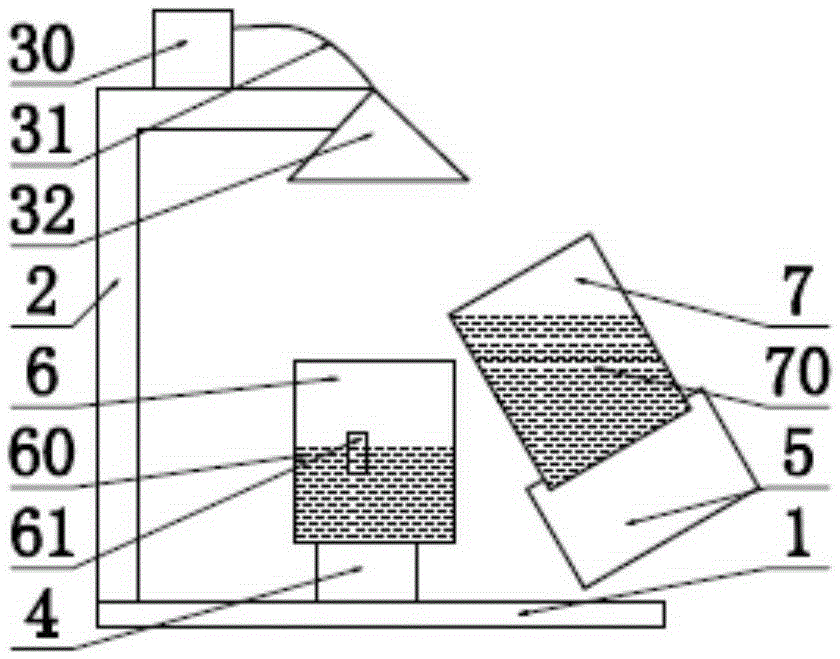

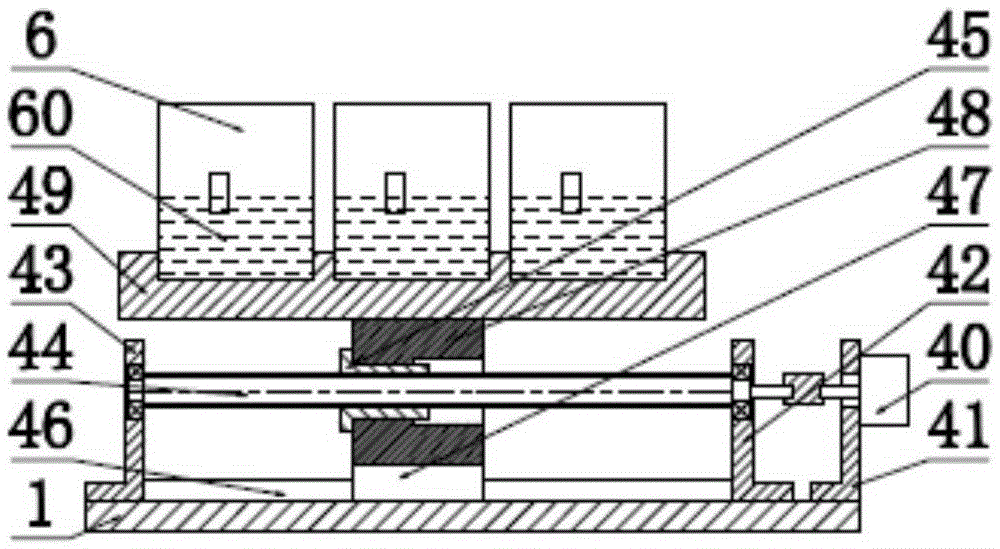

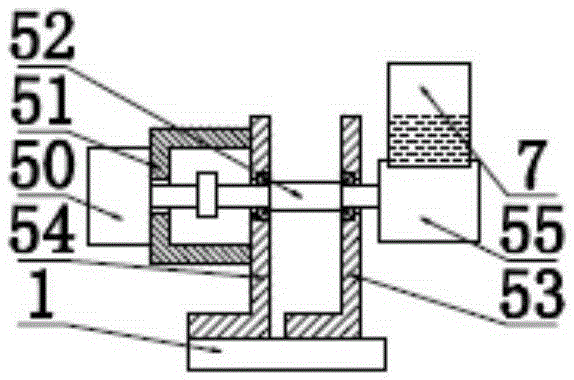

[0016] combine figure 1 , figure 2 and image 3 , the sodium hydroxide calibration device directly connected to the translational base in the sulfur determination meter of the present invention includes an L bracket 2 installed on the bottom plate 1, a beaker translation module 4 and a measuring cylinder tilting module 5, and is installed on the L bracket 2 PC 30 and high-definition camera 32, beaker 6, measuring cylinder 7, sulfuric acid solution 60 and PH test paper 61 installed in the beaker 6, sodium hydroxide solution 70 installed in the measuring cylinder 7; PC 30 passes through the signal line 31 Connect with high-definition camera 32.

[0017] combine figure 1 , figure 2 and image 3 , the beaker translation module 4 includes the second lead screw bracket 43, the linear guide rail 46, the first lead screw support 42 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com