Light guide plate of PS material and with projection structures

A light guide plate and material technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of complex processing technology of light guide plate, uneven light output, and difficult processing of groove structure, so as to improve the brightness of light source, uniform light output, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

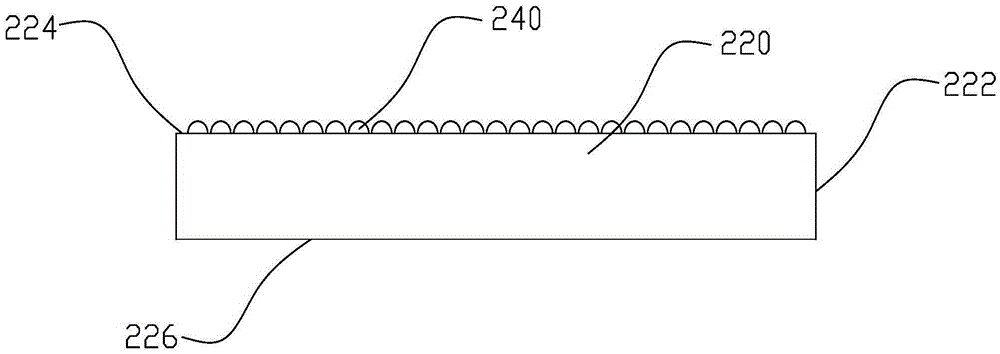

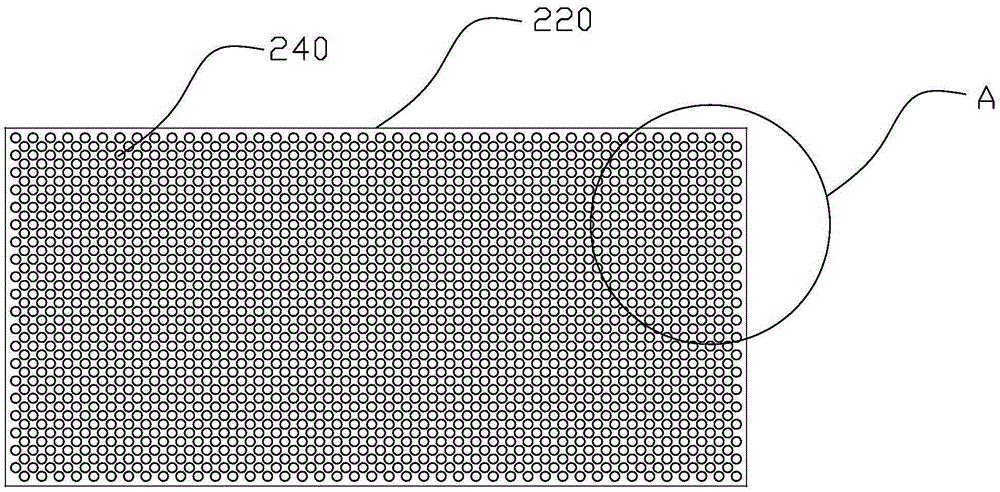

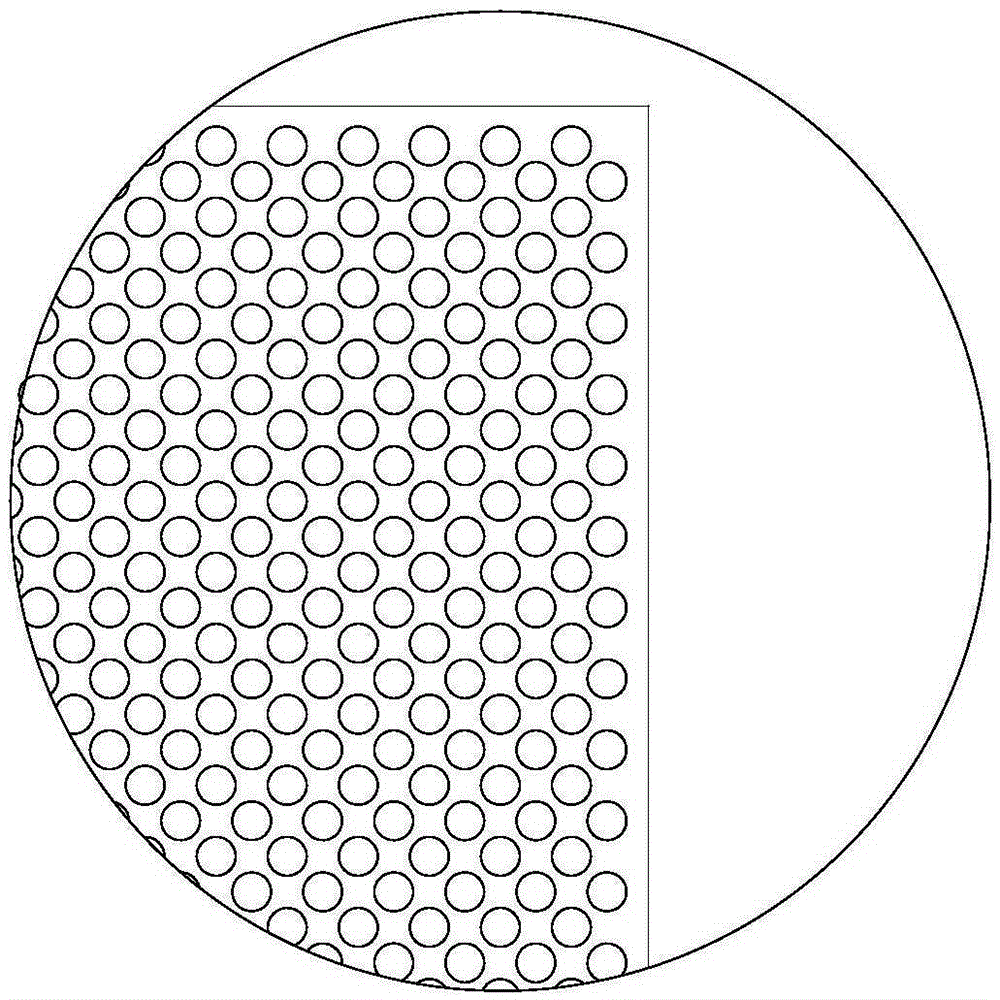

[0024] The light exit surface 224 is provided with a plurality of spherical protrusions 240 that are staggered and equally spaced and have the same structure. The material of the spherical protrusions 240 is PS material. The diameter and height of the spherical protrusions 240 should be moderate, and the light guide plate body 220 should be too large. Thickness affects the light transmittance. If it is too small, it will affect the scattering effect of the light guide plate body 220 on the light beam 300. After measurement, it is found that when the light guide plate body 220 is made of PS, the diameter of the spherical protrusion 240 is 240-265um and the height is 175- 200um is the best; in addition, the distance between adjacent spherical protrusions 240 is 295-330um, which is too large to affect the scattering effect of the light guide plate beam 300, and too small will cause mutual interference. In this embodiment, the diameter of the spherical protrusions 240 is 240um, the ...

Embodiment 2

[0027] The structure of this embodiment is the same as that of embodiment 1, but the difference is: the diameter of the spherical protrusion 240 is 252.5um, the height of the spherical protrusion 240 is 187.5um, and the distance between adjacent spherical protrusions 240 in each row and column It is 312.5um, and the thickness of the light guide plate body 220 is 2.5mm.

Embodiment 3

[0029] The structure of this embodiment is the same as that of embodiment 1, but the difference is that the diameter of the spherical protrusion 240 is 265um, the height of the spherical protrusion 240 is 200um, and the distance between adjacent spherical protrusions 240 in each row and column is 330um. , The thickness of the light guide plate body 220 is 3.0 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com