High-performance crosslinked ethylene and tetrafluoroethene copolymer insulated cable and preparation method thereof

A technology of cross-linked ethylene and tetrafluoroethylene, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of performance constraints of aerospace products, difficult insulation, mechanical properties and chemical stability, etc., to achieve tensile strength Effects of increased strength, excellent insulation, and reduced outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

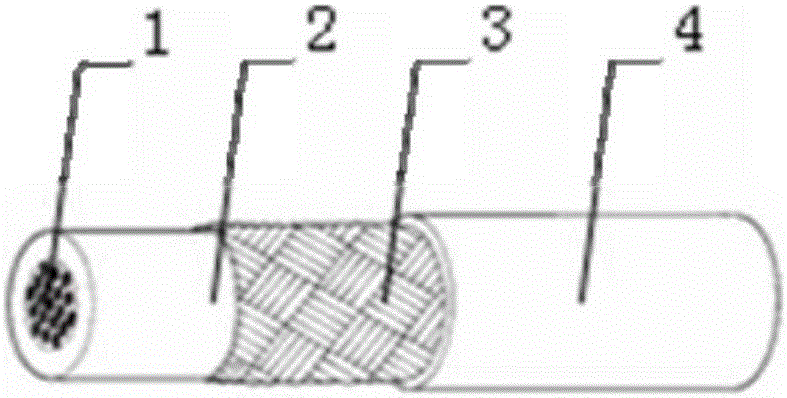

[0024] The present invention also provides a method for preparing the above-mentioned high-performance cross-linked ethylene-tetrafluoroethylene copolymer insulated cable, comprising:

[0025] 1) extruding the cross-linked ethylene-tetrafluoroethylene copolymer on the outside of the wire 1 to form an insulating sleeve 2;

[0026] 2) The silver-plated aramid yarn is paralleled and woven on the outside of the insulating sleeve 2 to form a shielding sleeve 3;

[0027] 3) Extrude the cross-linked ethylene-tetrafluoroethylene copolymer on the outside of the shielding sheath 3 to form a sheath 4 .

[0028] In the above preparation method, the specific preparation method of silver-plated aramid fiber can be any conventional method in the art, but in order to further improve the insulation, mechanical properties, radiation resistance and vacuum environment of the insulated cable made Chemical stability, preferably, before step 2), the method also includes: soaking the aramid fiber in...

Embodiment 1

[0031] 1) Soak the aramid fiber in a hydrochloric acid solution with a concentration of 55% by weight, then take it out and plate a silver layer with a thickness of 1.0 μm on the outer surface of the aramid fiber to obtain a silver-plated aramid fiber.

[0032] 2) Twisting the centers of multiple strands of silver-plated copper wires in the same direction to form a conductor 1;

[0033] 3) Extruding the cross-linked ethylene-tetrafluoroethylene copolymer on the outside of the wire 1 to form an insulating sleeve 2 with a thickness of 0.15mm;

[0034] 4) The silver-plated aramid yarn is paralleled and woven on the outside of the insulating sleeve 2 to form a shielding sleeve 3 with a thickness of 0.05 mm;

[0035] 5) Extrude the cross-linked ethylene-tetrafluoroethylene copolymer on the outside of the shielding sheath 3 to form a sheath 4 with a thickness of 0.20 mm to obtain an insulated cable A1; wherein, the area of the diameter section of the insulated cable is used as a b...

Embodiment 2

[0037] 1) Soak the aramid fiber in a sulfuric acid solution with a concentration of 60% by weight, then take it out and plate a silver layer with a thickness of 1.5 μm on the outer surface of the aramid fiber to obtain a silver-plated aramid fiber.

[0038] 2) Twisting the centers of multiple strands of silver-plated copper wires in the same direction to form a conductor 1;

[0039] 3) Extruding the cross-linked ethylene-tetrafluoroethylene copolymer on the outside of the wire 1 to form an insulating sleeve 2 with a thickness of 0.18 mm;

[0040] 4) The silver-plated aramid yarn is paralleled and woven on the outside of the insulating sleeve 2 to form a shielding sleeve 3 with a thickness of 0.08mm;

[0041] 5) Extrude the cross-linked ethylene-tetrafluoroethylene copolymer on the outside of the shielding sheath 3 to form a sheath 4 with a thickness of 0.22 mm to obtain the insulated cable A2; wherein, the area of the diameter section of the insulated cable is used as a benc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com