Electrochemical battery and preparation method thereof

An electrochemical and battery technology, applied in the field of electrochemical batteries, can solve problems such as packaging failure, and achieve the effect of solving drop and improving packaging reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

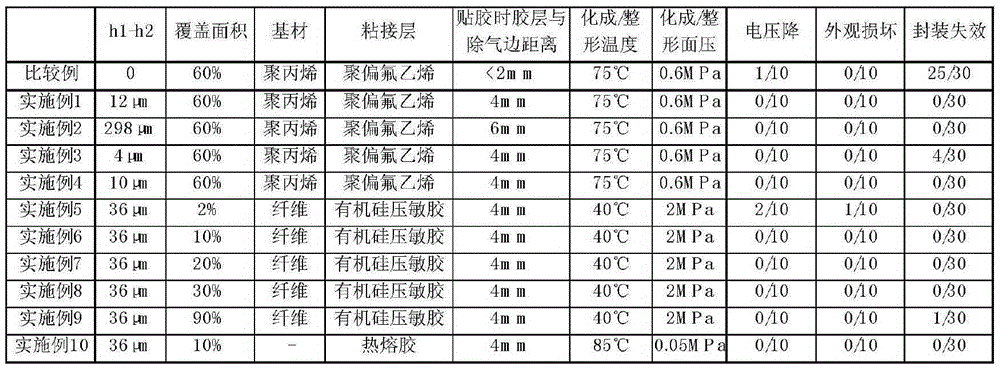

Examples

Embodiment 1

[0034] Embodiment 1, different from the comparative example, the present embodiment comprises the following steps:

[0035]Bare cell preparation: select a separator with a thickness of 12 μm, and wind it together with the above-mentioned positive electrode sheet and negative electrode sheet, and control the negative electrode current collector, positive electrode coating, negative electrode coating, and separator at the end of the bare cell during winding. The same surface B1; the positive current collector ends on the other surface B2 of the bare cell, and the last edge of the bare cell bypassed by the positive current collector before the end is the degassing packaging edge, and the distance between the closing line and the degassing packaging edge is 4mm ;

[0036] Adhesive layer setting: select polypropylene as the base material and polyvinylidene fluoride as the adhesive layer, paste it on the surface of the positive electrode collector side of the bare cell, and the area...

Embodiment 2

[0038] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0039] Bare cell preparation: select a separator with a thickness of 12 μm, wind it together with the above-mentioned positive electrode sheet and negative electrode sheet, and control the positive electrode collector and separator to end on the same surface B1 of the bare cell during winding; the negative electrode collector, Double-sided positive coating layer and double-sided negative coating finish on the other surface B2 of the bare cell, and the last bare cell that is bypassed before the negative current collector, double-sided positive coating layer and double-sided negative coating are finished The edge is the edge of the degassing package, and the distance between the end line and the edge of the degassing package is 6mm;

[0040] Adhesive layer setting: Choose polypropylene as the base material and polyvinylidene fluoride as the adhesive tape, stick it on the surface of ...

Embodiment 3

[0042] Embodiment 3, different from Embodiment 1, this embodiment includes the following steps:

[0043] Positive electrode sheet preparation: select an aluminum foil with a thickness of 4 μm as the current collector, coat the positive electrode slurry on its surface, and obtain a positive electrode diaphragm with a thickness of 75 μm coated on one side after cold pressing;

[0044] The rest are the same as in Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com