Conductor line, current collector, and conductor line system

A technology for sliding wires and current collectors, which is applied in the direction of current collectors, current collectors, power collectors, etc., to achieve the effects of material saving, compact structure, and simplified manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

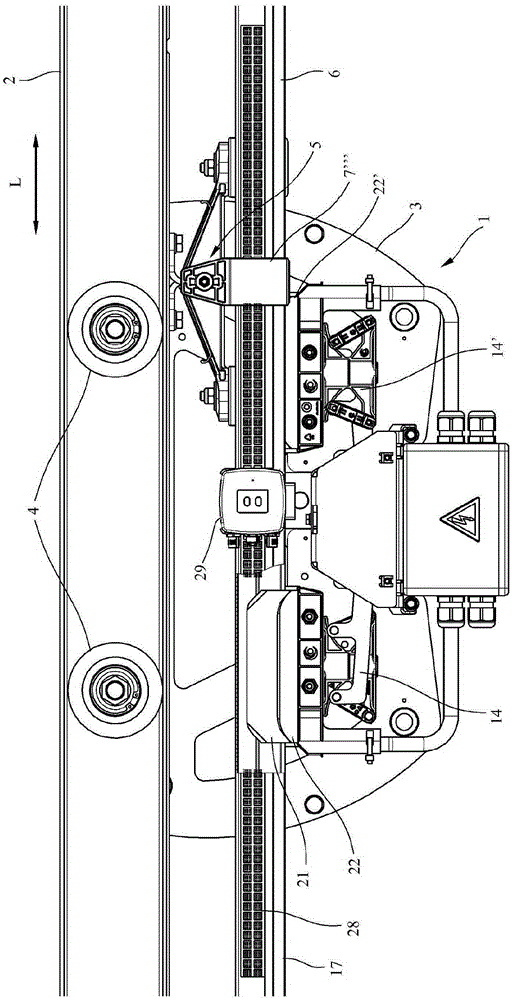

[0034] figure 1 A side plan view of a portion of a conductor line system 1 according to the invention is shown, which has a substantially double U-shaped rail 2 . The current collectors 3 of electrical loads (not shown) are movable on the rail 2 in the longitudinal direction L with impellers 4 . The current collector 3 is used to power an electrical load movable along the track 2, such as a container crane.

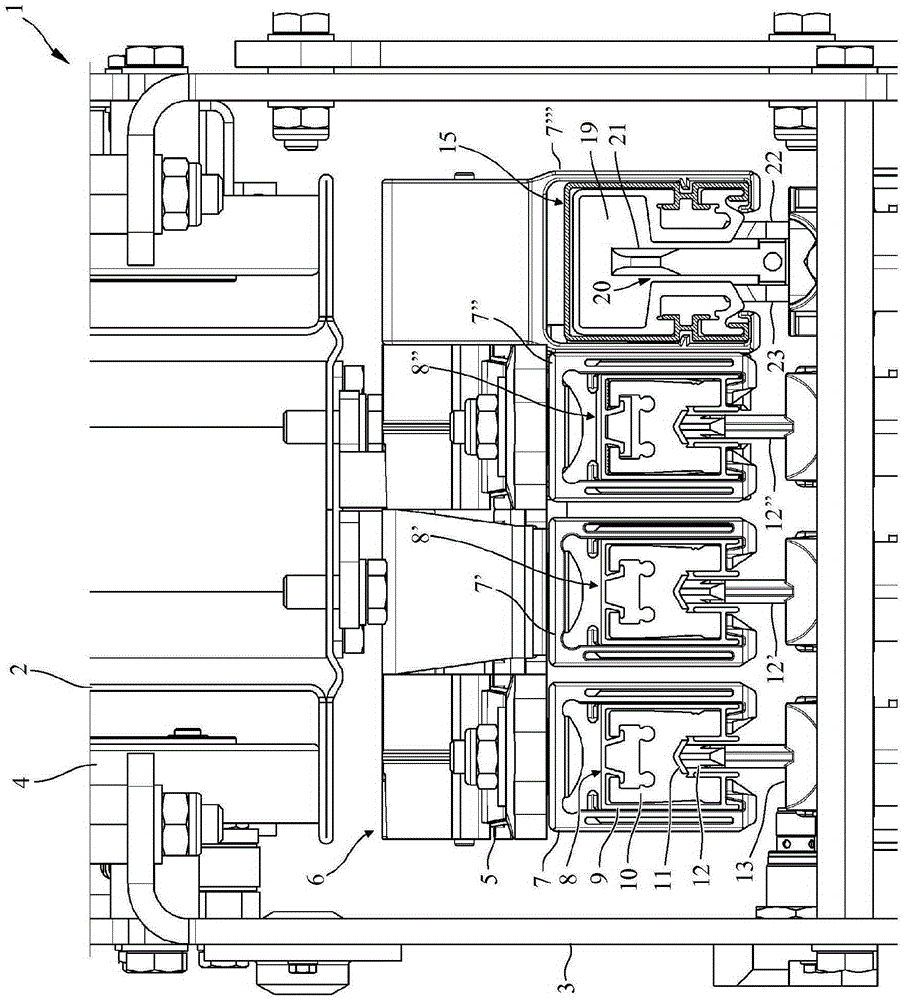

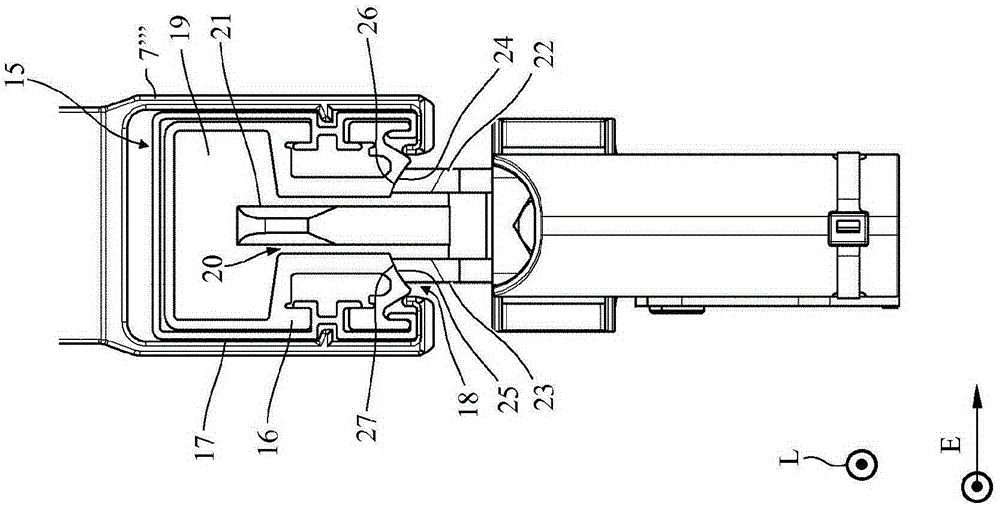

[0035] On the underside of the rail 2 , a conductor conductor 6 according to the invention is mounted suspended downward by means of conductor conductor holders 5 arranged at a distance from one another in the longitudinal direction L of the rail 2 . Sliding wire 6 is here Figures 2 to 5 Three conductor bundle holding structures 7, 7' and 7" arranged next to each other for holding elongated phase conductor bundles 8, 8' and 8" are clearly recognizable. Since the phase conductor bundles 8' and 8" are constructed identically to the phase conductor bundle 8, the descript...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com