Method for processing multiple kinds of tea with spring tea

A technology for tea processing and processing technology, which is applied in the field of processing various types of tea, can solve the problems of waste of tea green resources and low economic benefits, and achieve the effects of improving tea quality, improving competitiveness, and improving comprehensive utilization benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

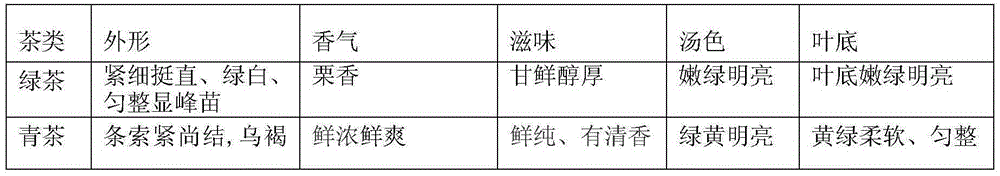

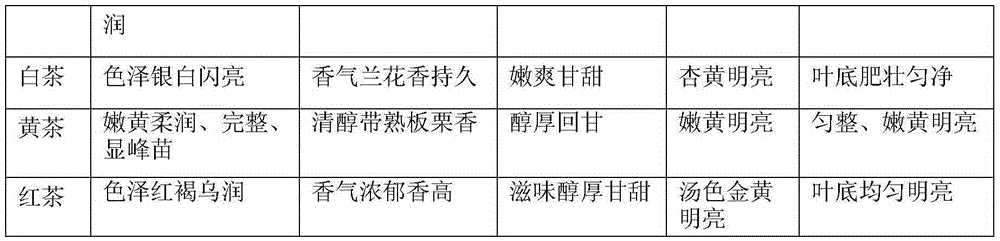

[0025] The method of processing multiple types of tea with fresh leaves of tea trees in spring refers to picking single buds, one bud and one leaf, or one bud with 1-2 leaves in spring to be used as raw materials for processing green tea, white tea, yellow tea, and high-grade black tea; picking A bud with 3-4 leaves or a pair of clipped leaves are used as the raw material for processing green tea or special black tea. The specific processing technology is as follows:

[0026] The processing technology of green tea is: pick single bud or one bud and one fresh leaf; spread the fresh leaf raw materials evenly on the withering machine, the thickness of spreading is 1cm, the withering temperature is 18°C, and the withering time is 5 hours, until the surface of the withered leaves loses Gloss, leaf quality becomes soft, leaf color is dark green, and the smell of grass gradually turns to fragrance or floral fragrance; the withered leaves are killed at a temperature of 300°C for 2.5 m...

Embodiment 2

[0032] The method of processing multiple types of tea with fresh leaves of tea trees in spring refers to picking single buds, one bud and one leaf, or one bud with 1-2 leaves in spring to be used as raw materials for processing green tea, white tea, yellow tea, and high-grade black tea; picking A bud with 3-4 leaves or a pair of clipped leaves are used as the raw material for processing green tea or special black tea. The specific processing technology is as follows:

[0033] The processing technology of green tea is: pick single bud or one bud and one fresh leaf; spread the fresh leaf raw materials evenly on the withering machine with a thickness of 1.5cm, the withering temperature is 22°C, and the withering time is 6 hours, until the surface of the withered leaves Loss of luster, leaf quality becomes soft, dark green leaf color, grassy smell gradually turns to fragrance or floral fragrance; withering leaves are killed at a temperature of 350°C for 2 minutes, and the color of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com