A Long Back Shank Large Diameter Internal Gear Broach

A technology of internal gear and large diameter, which is applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc. It can solve problems such as safety production accidents, broach breakage, and broach scrapping to achieve safety Guarantee, reduce the use of materials, and reduce the effect of tool manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

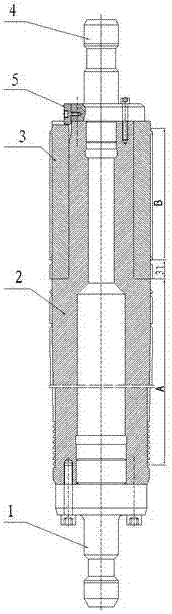

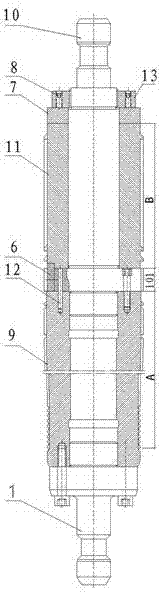

[0012] Such as figure 2 As shown, the large-diameter internal gear broach with long back handle of the present invention is an assembled structure, consisting of a front handle 1, a rough broach body 9 (hollow type), an extended back handle 10, a fine-drawing and expanding gear sleeve 11, and a cylindrical pin 12. Flat key 6, spacer 7, compression nut 13, set screw 8, etc. are assembled through precision machining. The rough broach body 9 is in the form of a single-diameter through hole and a straight cylinder with uniform wall thickness and an outer circle with equal tooth rise changes, which improves the heat treatment process performance. The front handle 1 and the extended rear handle 10 are bolted to the two ends of the rough broaching tool body 9 respectively, wherein the extended rear handle 10 and the rough broaching tool body 9 are limited in the circumferential direction by cylindrical pins 12, so that the extended rear handle 10 The guide tooth 101 of the belt is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com