Processing technology for processing fasteners

A processing technology and fastener technology, applied in the processing technology field of processing fasteners, can solve the problems of many workers and low work efficiency, and achieve the effects of saving labor, improving work efficiency and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing:

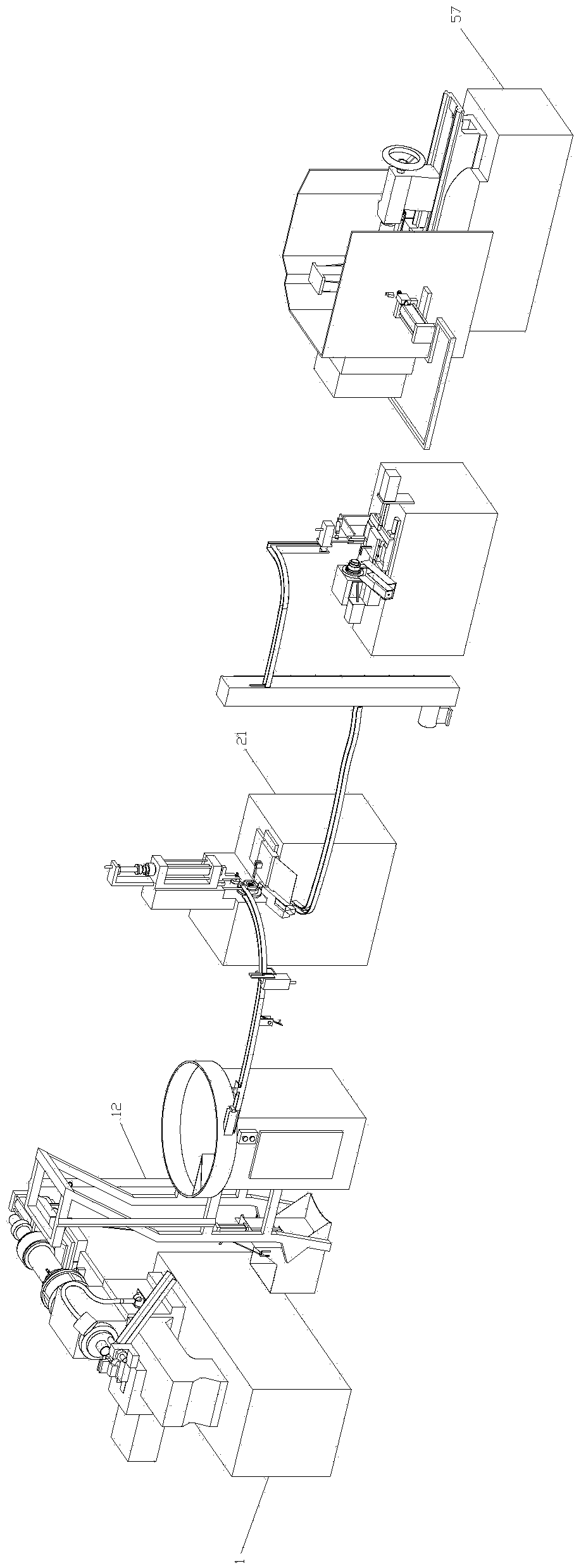

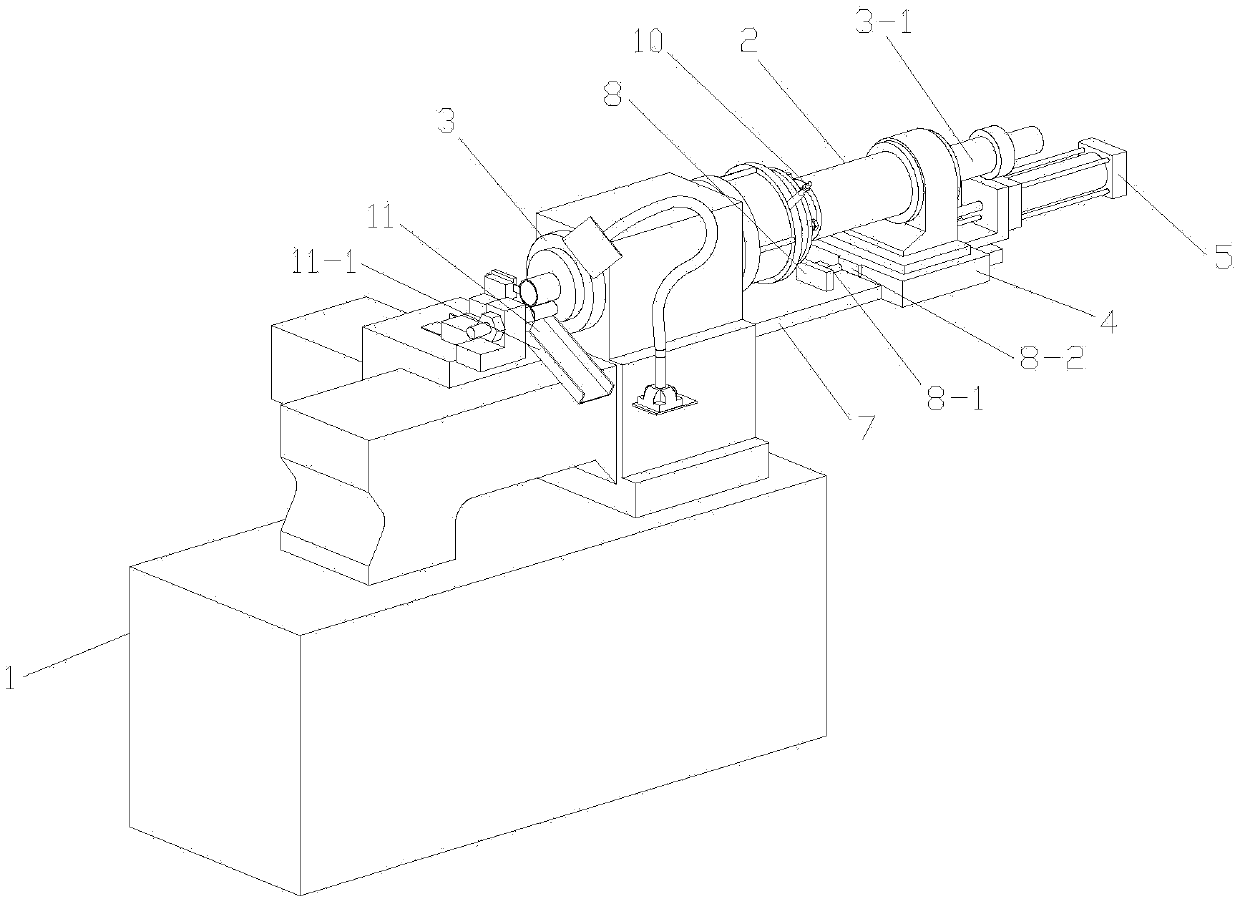

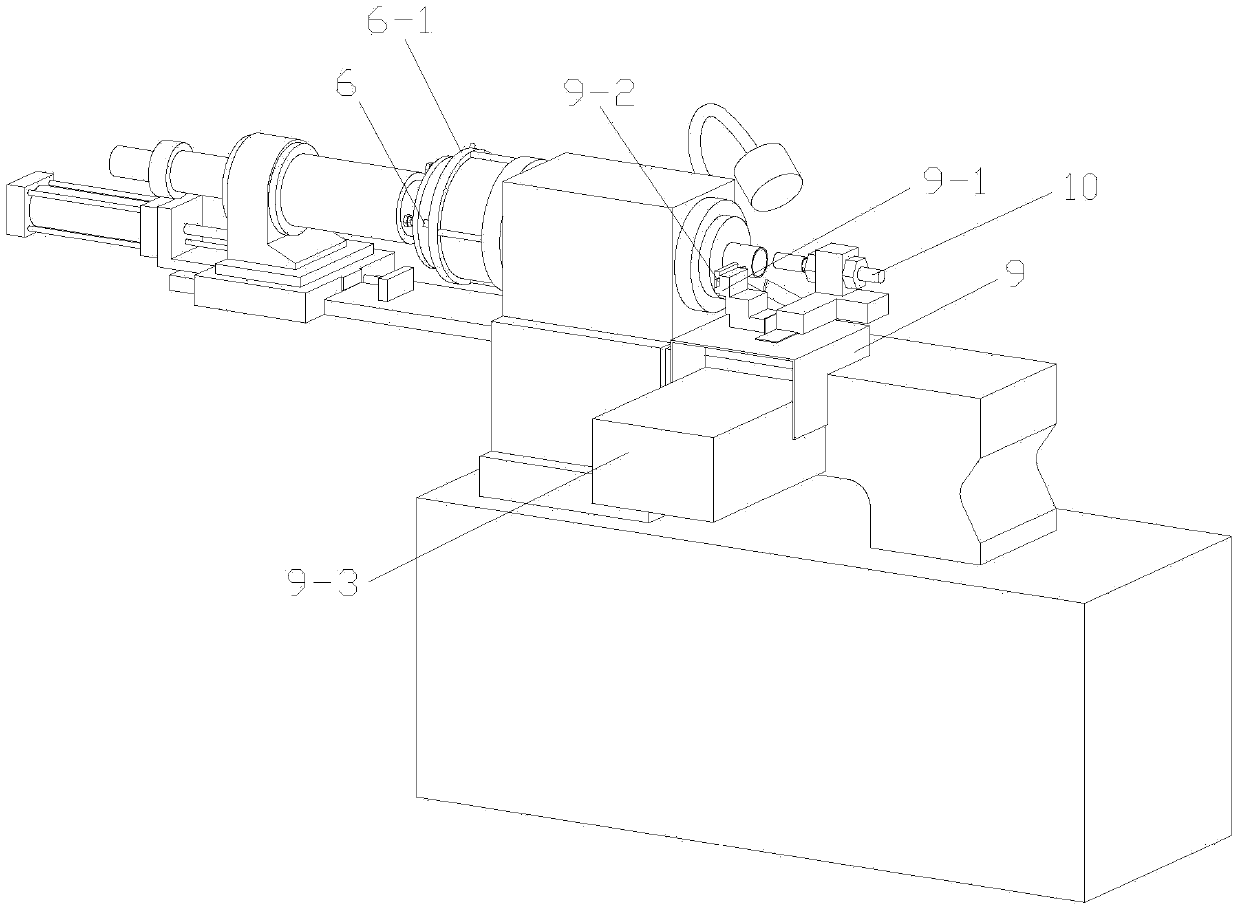

[0049] Refer to attached Figure 1-25 : This processing technology for processing fasteners, its processing steps are as follows:

[0050] (1) Install the long tube into the automatic pushing and cutting bed in the assembly line system, and fix it with a pneumatic chuck;

[0051] (2) Start the automatic pushing and cutting bed, and cut the long pipe into several fasteners through the cutting knife;

[0052] (3) The cut fasteners fall into the blanking plate and slide into the hopper of the pulling machine through the blanking plate;

[0053] (4) After the fasteners in the hopper reach a certain amount, start the pulling machine, pull the fasteners in the hopper to a suitable working height, and then send them to the feeding barrel;

[0054] (5) The fasteners in the feeding barrel are sent to the fastener processing machine through the first feeding channel;

[0055] (6) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com