Pneumatic fixing clamp

A fixed fixture, pneumatic technology, applied in the field of tooling fixtures, can solve the problems of reducing production efficiency, easy to produce deviation in size, unfavorable production, etc., to achieve the effects of improving stability, improving qualification rate, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

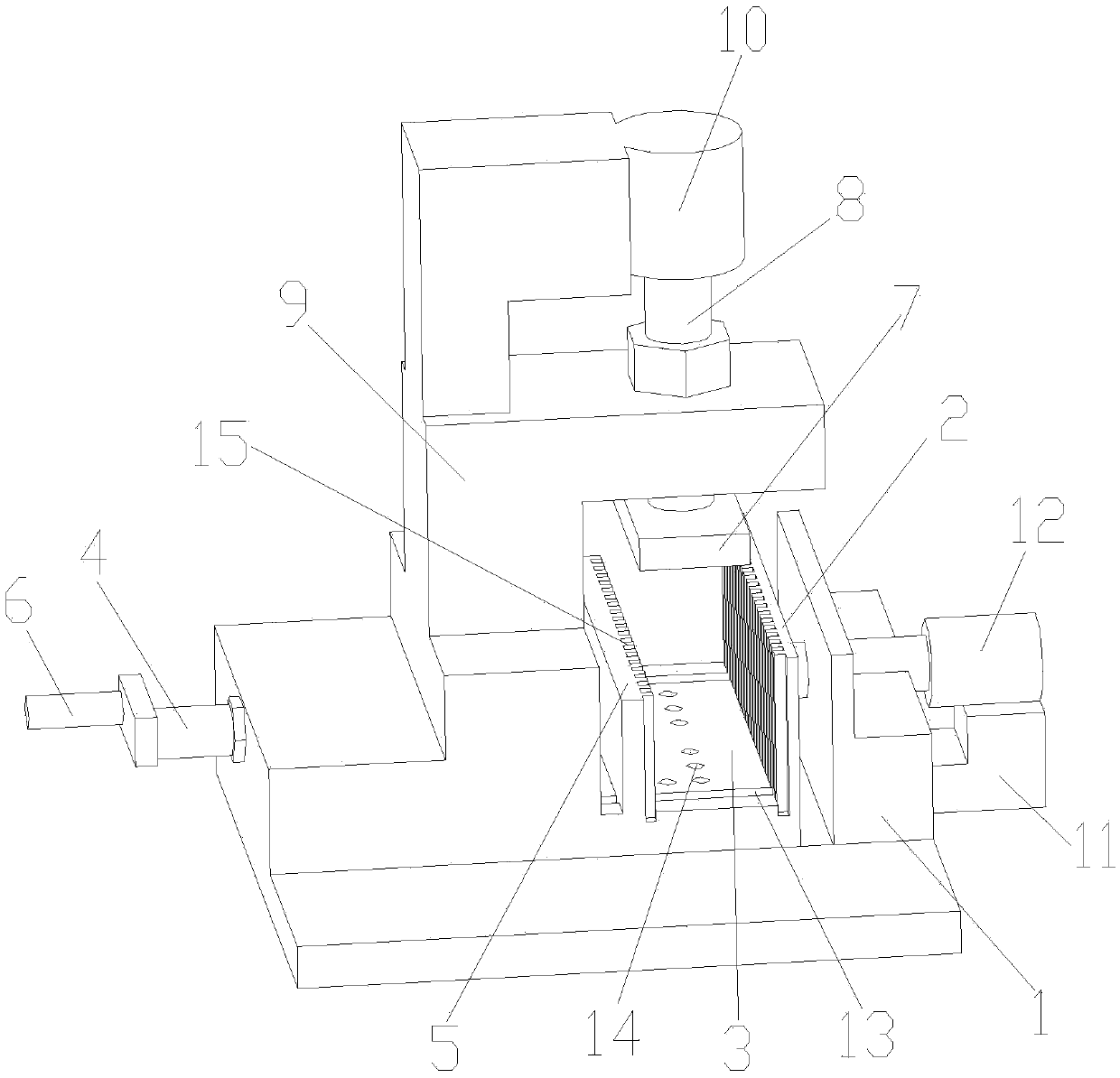

[0013] The present invention is described below in conjunction with accompanying drawing.

[0014] as attached figure 1 Shown is a pneumatic fixing fixture of the present invention, including a base 1 and a fixed baffle 2; an installation groove 3 is provided between the base 1 and the fixed baffle 2; The clamping block 5; the other end of the screw 4 protrudes from the base 1, and is connected with a screw handle 6; a pressing block 7 is arranged above the installation groove 3; the pressing block 7 is arranged on one end of the pressing rod 8 It is fixed on the fixed frame 9; the other end of the pressure rod 8 is connected with a downward pressure cylinder 10; one side of the base 1 is provided with a compression cylinder 12 through a support seat 11; the piston rod of the compression cylinder 12 passes through The base 1 is connected to the fixed baffle 2; the installation groove 3 is provided with a chute 13; the installation groove 3 is provided with a drainage hole 14;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com